Embarking on a utility-scale solar project represents a significant investment and a commitment to sustainable energy. Ensuring the longevity, efficiency, and safety of such an endeavor hinges critically on robust quality control practices. Without a systematic approach, even minor oversights can lead to substantial financial losses, underperformance, and costly rectifications down the line. This is precisely where a well-structured utility solar quality control checklist template becomes an indispensable tool, guiding every phase of your project from initial design to final commissioning and beyond.

Poor quality control is not merely an inconvenience; it can manifest as underperforming modules, premature equipment failure, grid instability, and even safety hazards for personnel and the surrounding community. The complex interplay of electrical, mechanical, and civil engineering components within a solar farm demands a meticulous eye for detail and adherence to the highest industry standards. Overlooking critical checkpoints can compromise not only the immediate operational efficiency but also the long-term return on investment.

This article delves into the various stages of quality control essential for utility solar projects, outlining key areas where a comprehensive checklist template can make a profound difference. We’ll explore how such a template can streamline inspections, standardize procedures, and ultimately safeguard your investment, ensuring your solar farm operates at peak performance for its entire lifespan.

The Foundation of Flawless Solar Farms: A Deep Dive into Quality Control Stages

Achieving a high-quality utility-scale solar farm is not a one-time event but rather a continuous process that integrates meticulous checks and balances across every project phase. From the drawing board to the operational phase, each stage presents unique challenges and opportunities for quality assurance. A robust quality control framework ensures that potential issues are identified and addressed proactively, preventing them from escalating into costly problems.

Pre-Construction and Design Review

Before any ground is broken, the initial design and planning phase requires intense scrutiny. This involves reviewing site assessments, geotechnical surveys, environmental impact studies, and ensuring that all design specifications comply with local, national, and international codes and standards. The checklist at this stage would focus on verifying the structural integrity of proposed racking systems, electrical schematics, inverter sizing, and grid interconnection plans. It’s crucial to confirm that the chosen technology is appropriate for the site’s specific conditions and that performance projections are realistic and achievable.

Procurement and Material Verification

The quality of components directly impacts the overall performance and lifespan of a solar farm. This stage of quality control focuses on vetting suppliers, ensuring all modules, inverters, transformers, and balance-of-system (BOS) components meet stringent industry certifications (e.g., IEC, UL). Upon delivery, a comprehensive checklist guides the inspection of materials for any damage during transit, verifying serial numbers, and confirming specifications against purchase orders. Substandard materials at this stage can cripple a project before it even begins.

Installation Oversight and Field Inspections

This is arguably the most critical phase for on-site quality control. Installation oversight covers everything from foundation pouring and racking assembly to module placement and electrical wiring. Inspectors use the checklist to verify proper torque settings for structural bolts, correct module orientation and tilt, secure electrical connections, and proper trenching for cable runs. Attention to detail here prevents common issues like loose connections, incorrect polarity, or structural weaknesses that could lead to failures or reduced performance over time. Safety protocols for personnel and equipment during installation are also a paramount focus.

Commissioning and Performance Testing

Once installation is complete, the commissioning phase thoroughly tests the entire system before it goes live. This includes a series of electrical tests such as IV curve tracing for modules, insulation resistance tests, and thermal imaging to detect hot spots. Functional testing of inverters, transformers, and the SCADA monitoring system ensures all components are communicating correctly and performing as expected. The checklist guides the verification of grid synchronization, protection relay settings, and overall system functionality to meet design specifications and performance guarantees.

Post-Commissioning and Ongoing Monitoring

Quality control doesn’t end when the solar farm is operational. Continuous monitoring of performance data, regular preventative maintenance, and timely identification of anomalies are crucial for long-term asset health. The checklist here helps in establishing routines for thermal imaging inspections, module cleaning, vegetation management, and reviewing SCADA alerts. This ongoing commitment to quality ensures the solar farm maintains optimal efficiency, minimizes downtime, and extends its productive life cycle, safeguarding the initial investment for decades.

Crafting Your Own Robust Utility Solar Quality Control Checklist

While the principles of quality control remain consistent, every utility-scale solar project is unique. Factors such as site topography, specific technology choices, local environmental regulations, and grid codes necessitate a customizable approach to your quality assurance framework. A generic checklist might cover broad areas, but an effective one must be adaptable, reflecting the precise requirements and challenges of your particular project, empowering your teams to ensure adherence to the highest standards.

Developing a tailored checklist fosters a sense of ownership among project teams and allows for continuous improvement based on lessons learned from previous phases or projects. It acts as a living document, evolving with new industry best practices, technological advancements, and regulatory updates. Furthermore, a customized approach helps in training new staff, ensuring that all personnel understand the specific quality benchmarks and processes relevant to the project at hand, reducing errors and enhancing overall efficiency.

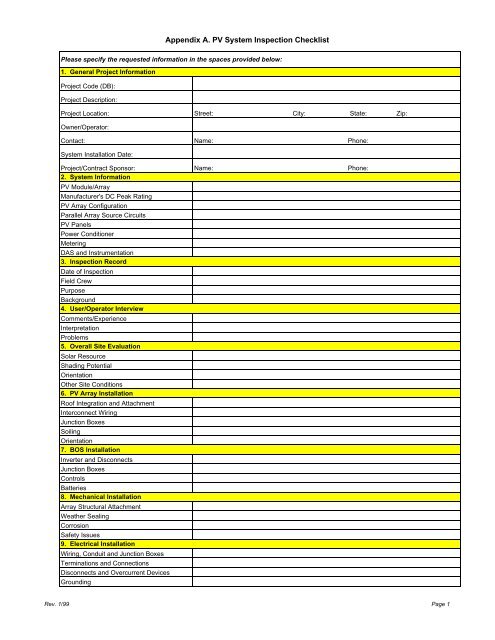

To create an effective utility solar quality control checklist template, consider these essential elements:

- Project Specifics: Include fields for project name, location, inspection date, and inspector names.

- Categorized Sections: Organize the checklist into logical phases such as Pre-Construction, Procurement, Mechanical Installation, Electrical Installation, Safety, and Commissioning.

- Detailed Checkpoints: For each category, list specific items to be inspected, accompanied by clear pass/fail criteria or conformance requirements.

- Documentation Requirements: Specify what documents (e.g., test reports, permits, material certifications) need to be reviewed or collected at each stage.

- Corrective Action Section: Provide space for noting any non-conformances, required corrective actions, responsible parties, and target completion dates.

- Sign-off and Approval: Include sections for relevant stakeholders to sign off, indicating their review and approval of the completed checks.

- References: Add columns or notes to reference relevant codes, standards, or project-specific documentation.

Implementing a well-designed and regularly updated utility solar quality control checklist template is a strategic move that underpins the success and profitability of any large-scale solar endeavor. It moves quality from an aspiration to an actionable, measurable reality, ensuring every component, connection, and process contributes to a reliable and high-performing asset for years to come.