Ensuring consistent product quality is paramount for any business aiming for long-term success and customer satisfaction. It’s not enough to simply hope for the best; a structured approach is crucial. That’s precisely where a robust product quality inspection checklist template comes into play, providing a systematic framework to catch potential issues before they escalate and reach your valuable customers.

Think of it as your quality assurance roadmap. Without one, inspections can feel haphazard, key details might be overlooked, and consistency across different batches or production runs becomes a distant dream. A well-designed checklist brings clarity, standardizes processes, and empowers your team to perform thorough, reliable checks every single time.

This guide will walk you through the essential components of creating such a powerful tool, explaining why each element matters and how to tailor it to your specific needs. By the end, you’ll have a clear understanding of how to implement an inspection system that truly elevates your product standards.

The Anatomy of an Effective Product Quality Inspection Checklist

A truly effective product quality inspection checklist isn’t just a simple list of items; it’s a meticulously crafted document that guides inspectors through every critical aspect of your product. It transforms a subjective visual assessment into an objective, repeatable process. Let’s break down the key sections you’ll want to include to ensure comprehensive coverage.

Identifying Information

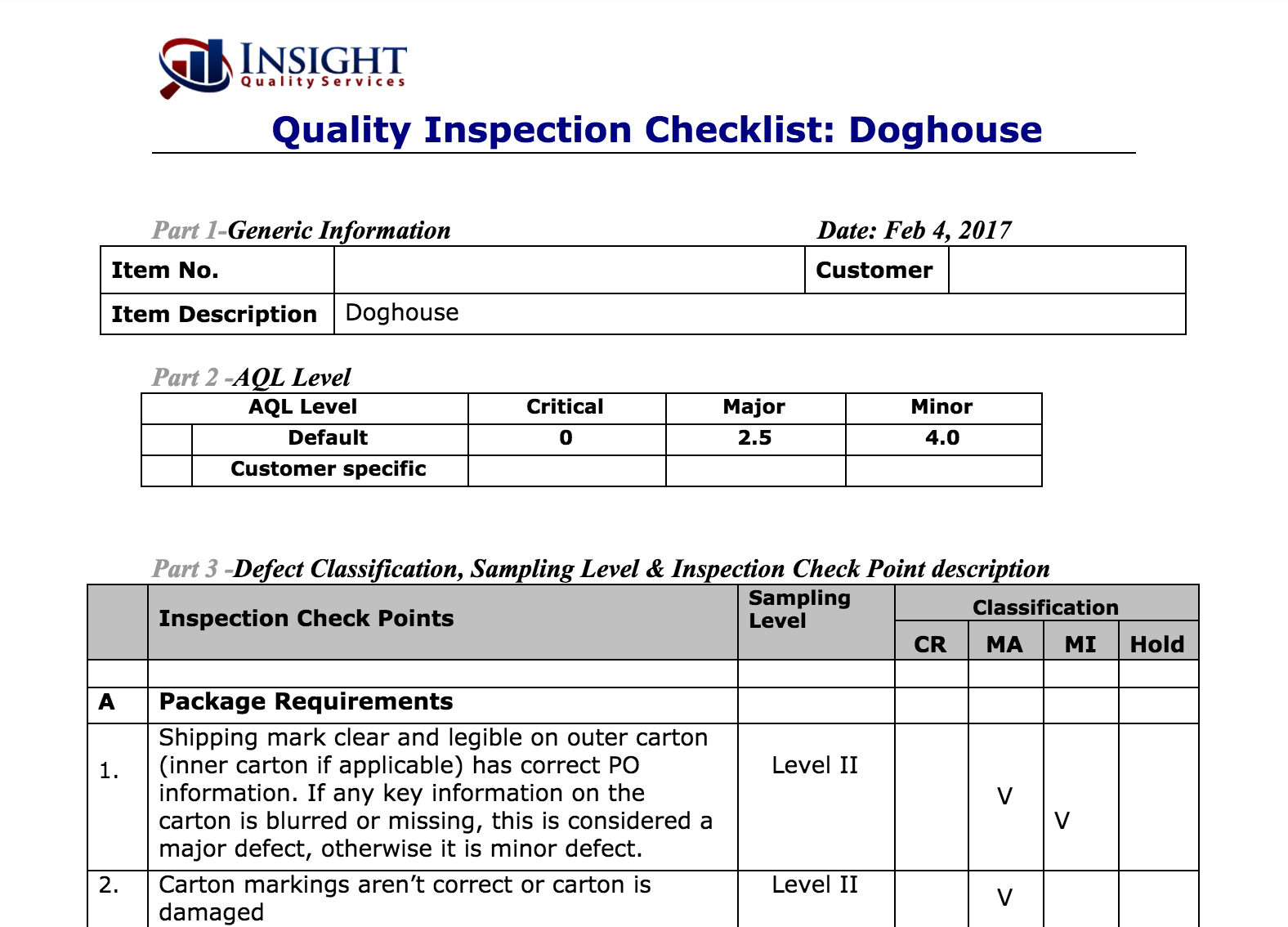

Every good checklist starts with the basics. You need to know what you’re inspecting, when, and by whom. This section typically includes the product name or SKU, batch number, date of inspection, time of inspection, and the name or ID of the inspector. This data is vital for traceability and for quickly pinpointing when and where a potential issue arose.

Key Inspection Criteria

This is the heart of your checklist. Here, you’ll detail specific aspects to be checked. These criteria should be measurable, observable, and directly related to your product’s specifications and customer expectations. For example, if it’s a physical product, you might look at dimensions, weight, color, material integrity, or packaging. For software, it could be functionality, user interface responsiveness, or data integrity.

Pass/Fail Parameters and Tolerances

For each inspection criterion, it’s crucial to define what constitutes a “pass” and what signals a “fail.” This removes ambiguity and ensures all inspectors are working with the same standards. Where applicable, specify acceptable tolerances. For instance, “Length: 10cm +/- 0.5cm” is far more useful than just “Check length.” Providing clear acceptable ranges prevents subjective interpretations and ensures consistent quality decisions.

Tools and Methods Required

Some inspections require specific tools, like calipers, multimeters, or specialized software. This section should list all necessary equipment and, if relevant, outline the specific method to be used for each check. This ensures inspectors are prepared and follow standardized testing procedures, minimizing variability in results.

Defect Classification and Action Plan

It’s inevitable that defects will be found occasionally. Your checklist should include a way to classify these defects (e.g., critical, major, minor) and outline immediate next steps. Does a critical defect halt the entire batch? Does a minor defect require re-work? Having a pre-defined action plan ensures that issues are addressed promptly and correctly, preventing substandard products from reaching the market.

Sign-Off and Review

Finally, a section for sign-off by the inspector and, if necessary, by a supervisor or quality manager, adds an important layer of accountability. This also provides an opportunity for a final review of the inspection results. Regular reviews of the checklist itself are also crucial to ensure it remains relevant and effective as products or processes evolve.

Implementing and Optimizing Your Quality Inspection Process

Having a fantastic product quality inspection checklist template is one thing, but successfully integrating it into your daily operations is another. It requires training, consistency, and a commitment to continuous improvement. Start by thoroughly training all your inspection staff on how to use the checklist, ensuring they understand each criterion, the tools involved, and the implications of their findings. Regular refresher training can also be beneficial, especially as products or processes evolve.

Don’t just set it and forget it. Regularly review the effectiveness of your checklist. Are there recurring issues that aren’t being caught early enough? Are certain inspection points consistently passing without issue, perhaps indicating they could be streamlined or even automated? Gather feedback from your inspection team they are on the front lines and often have valuable insights into how to improve the process. This iterative approach ensures your quality checks remain efficient and relevant.

The real power of a well-implemented checklist extends beyond just defect detection. It fosters a culture of quality throughout your organization, providing clear expectations and accountability. Over time, the data collected from these inspections can be invaluable for identifying trends, improving manufacturing processes, and making informed decisions about product design or supplier selection. Remember, this isn’t just about avoiding bad products; it’s about consistently delivering excellence. Your product quality inpspection checklist template becomes a living document, evolving with your business to maintain the highest standards.

Ultimately, investing time and effort into creating and maintaining a robust quality inspection system pays dividends far beyond simply catching errors. It builds customer trust, reduces costly returns and rework, and strengthens your brand’s reputation for reliability. By standardizing your checks, you empower your team and safeguard your product’s integrity.

Embrace the power of a structured approach to quality control. It’s a continuous journey of refinement, but with a solid foundation like a well-crafted inspection checklist, you’re well-equipped to navigate the complexities of production and consistently deliver products that not only meet but exceed expectations.