In the bustling world of manufacturing, where precision and efficiency are paramount, even the slightest deviation can ripple through production, affecting quality, cost, and delivery times. Ensuring every step of your production line operates at its peak isn’t just good practice; it’s essential for sustained success and competitive advantage. That’s where a systematic approach to evaluating your processes truly shines.

Imagine having a clear, structured way to review your operations, pinpointing areas of strength and identifying opportunities for improvement. This proactive approach helps prevent costly errors before they occur and fosters a culture of continuous enhancement. The backbone of such an approach is a well-designed tool, and a robust manufacturing process audit checklist template is exactly that. It’s not just a document; it’s a strategic asset for operational excellence.

Why a Manufacturing Process Audit is Crucial for Your Business

A manufacturing process audit is essentially a health check for your production system. It’s a systematic, independent examination to determine whether activities and related results comply with planned arrangements and whether these arrangements are implemented effectively and are suitable to achieve objectives. Think of it as an ongoing commitment to perfection, or at least, continuous improvement.

The benefits of regularly conducting these audits are numerous and far-reaching. They help in identifying bottlenecks that slow down production, ensure adherence to quality standards, reduce waste in terms of materials and time, and guarantee compliance with industry regulations and safety protocols. Without a structured audit, issues might linger unnoticed, gradually eroding efficiency and increasing operational risks.

Moreover, these audits are incredibly proactive. They don’t just react to problems; they uncover potential issues before they escalate into major disruptions. By systematically reviewing each stage of your manufacturing process, you gain invaluable insights that drive informed decision-making and strategic improvements. It’s about building resilience and agility into your operations.

Key Areas a Checklist Template Covers

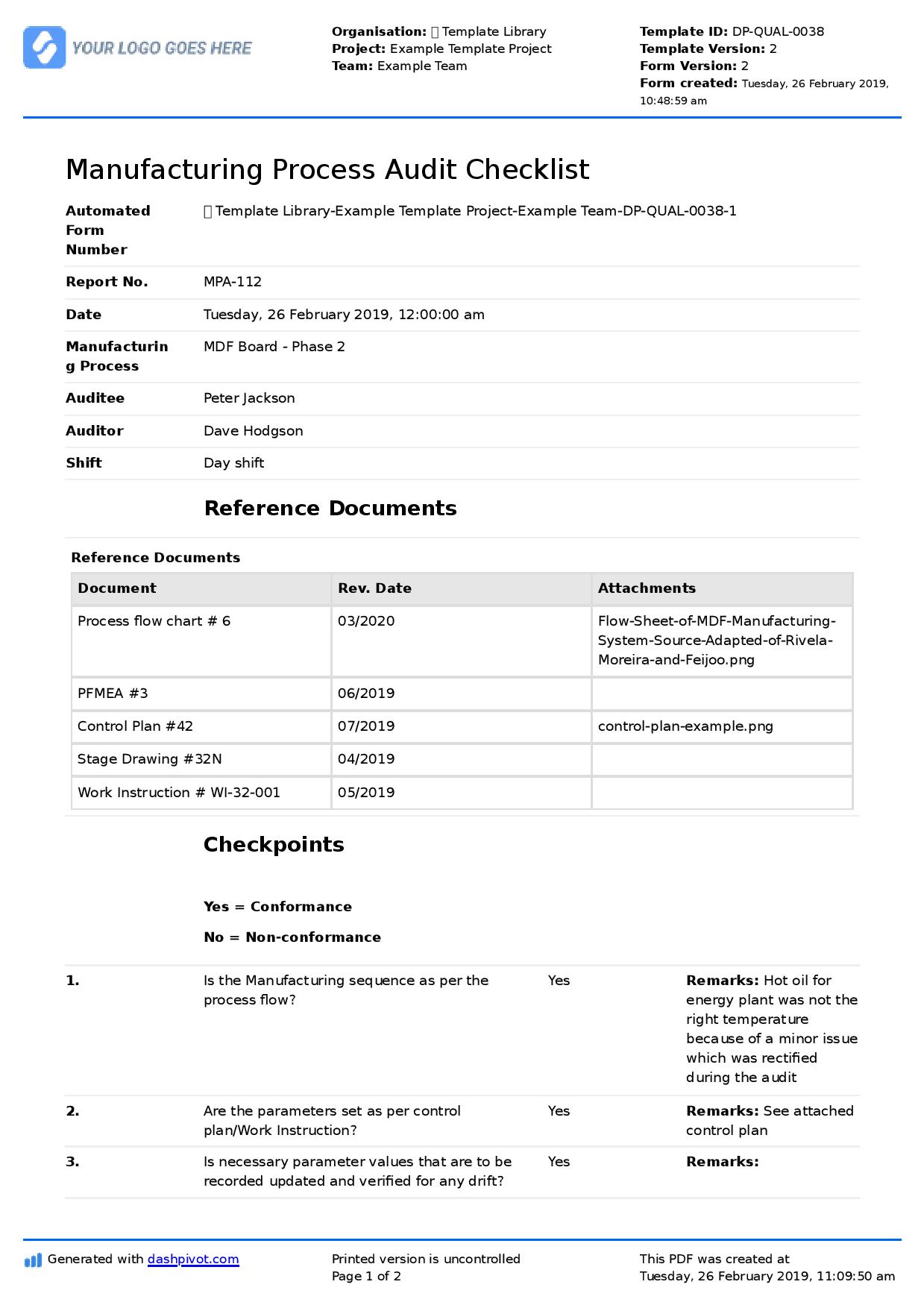

A comprehensive checklist template is designed to ensure no stone is left unturned during an audit. It breaks down the complex manufacturing environment into manageable, auditable sections, making the process less daunting and more effective. By using a structured format, you ensure consistency across audits, allowing for better tracking of progress and trends over time.

* Raw Material Inspection and Storage: Ensuring incoming materials meet specifications and are stored correctly to prevent damage or degradation.

* Production Line Operations: Verifying that machinery is set up correctly, procedures are followed, and waste is minimized.

* Equipment Maintenance and Calibration: Checking that all equipment is regularly maintained and calibrated to ensure accuracy and prevent breakdowns.

* Quality Control Points: Confirming that quality checks are performed at critical stages, and non-conforming products are handled appropriately.

* Personnel Training and Competency: Assessing whether staff are adequately trained for their roles and understand safety protocols.

* Documentation and Record Keeping: Ensuring all processes are properly documented, and records are maintained for traceability and compliance.

* Safety and Environmental Compliance: Verifying adherence to all relevant safety regulations and environmental standards.

By diligently working through each of these areas with a manufacturing process audit checklist template, you create a holistic view of your operational health, empowering your team to address weaknesses and capitalize on strengths. This systematic review is instrumental in fostering a culture of accountability and continuous improvement throughout your organization.

Building Your Effective Manufacturing Process Audit Checklist

Creating an effective manufacturing process audit checklist involves more than just listing a few questions. It requires a thoughtful approach to scope, detail, and usability. The goal is to design a tool that not only identifies problems but also facilitates actionable solutions, driving genuine improvements in your production landscape.

Start by defining the specific objectives of your audit. Are you focused on quality improvement, cost reduction, compliance, or a general operational review? The scope will dictate the level of detail and the specific areas your checklist should emphasize. Remember, a one-size-fits-all approach rarely yields the best results in the diverse world of manufacturing. Customization is key to making your checklist truly impactful.

A well-crafted checklist should feature clear, concise questions that leave no room for ambiguity. Instead of vague prompts, opt for specific inquiries that demand a definitive answer or observation. Incorporating a scoring system or a section for comments and corrective actions can greatly enhance the checklist’s utility, transforming it from a simple data collection tool into a powerful instrument for process optimization.

* Define Scope and Objectives: Clearly outline what the audit aims to achieve and which processes it will cover.

* Categorize Audit Areas: Break down the manufacturing process into logical segments for easier evaluation.

* Formulate Clear Questions: Use specific, actionable questions that can be objectively answered.

* Include Compliance Checks: Integrate regulatory and internal standard requirements directly into the checklist.

* Design for Actionable Outcomes: Ensure space for observations, findings, and recommended corrective actions.

* Review and Update Regularly: Periodically revisit and revise your template to reflect changes in processes, technology, and regulations.

The practical application of your manufacturing process audit checklist template is where its true value becomes apparent. It provides a consistent framework for auditors, whether they are internal teams or external experts, ensuring that every audit is thorough and objective. The insights gained from these audits are then used to refine processes, enhance training, and invest in technology, pushing your manufacturing capabilities to new heights.

Embracing the power of regular manufacturing process audits, guided by a comprehensive checklist template, is a strategic investment in the future of your operations. It’s about more than just finding faults; it’s about nurturing a robust, efficient, and high-quality production environment that stands the test of time and market demands. This dedication to excellence ensures your business not only meets current standards but continually strives for superior performance.