Every business, regardless of its size or industry, faces pivotal moments where it needs to decide whether to produce a good or service in-house or procure it from an external supplier. This isn’t just a simple cost calculation; it’s a strategic choice with far-reaching implications for your operations, finances, and even your brand reputation. That’s where a robust make or buy decision checklist template becomes an indispensable tool, guiding you through the complexities and ensuring you make the most informed choice.

Navigating this decision can feel like a maze. Should you invest in new equipment and hire more staff to handle production internally? Or would outsourcing free up valuable resources, allowing you to focus on your core competencies and accelerate growth? The right answer isn’t always obvious, and a misstep can lead to increased costs, compromised quality, or missed opportunities.

This article aims to demystify the make or buy process, providing you with a clear framework to evaluate your options. We’ll explore the critical factors that influence these decisions and outline how a structured checklist can empower you to confidently choose the path that best aligns with your business objectives.

Unpacking the Make Or Buy Dilemma: More Than Just Costs

At its heart, a make or buy decision is about resource allocation and strategic positioning. It forces you to look inward at your capabilities and outward at the market, weighing the pros and cons of internal production versus external procurement. While cost is undoubtedly a significant factor, it’s rarely the only one. You also need to consider control, quality, flexibility, and even the long-term strategic direction of your company.

Consider the ‘making’ side. When you choose to produce something internally, you gain complete control over the process, from raw material sourcing to final quality inspection. This can be crucial for proprietary technologies, maintaining specific quality standards, or protecting intellectual property. It can also lead to economies of scale if your production volume is high enough, potentially reducing unit costs over time and fostering unique in-house expertise that becomes a competitive advantage.

However, making also comes with its own set of challenges. It requires significant upfront investment in machinery, infrastructure, and skilled labor. You become responsible for managing inventory, production schedules, and potential downtime. There’s also the risk of capacity constraints, where sudden increases in demand might overwhelm your internal capabilities, or conversely, idle capacity during slower periods can become a costly burden.

Now, let’s look at the ‘buying’ perspective. Outsourcing allows you to leverage the specialized expertise, efficiency, and scale of external providers. This can translate into faster time-to-market, access to cutting-edge technology without capital investment, and increased flexibility to scale production up or down as needed. It can also free up your internal resources, allowing your team to concentrate on your core business activities where you truly excel, potentially boosting innovation and overall profitability.

Yet, buying isn’t without its own set of complexities. You inherently cede some control over the production process, potentially impacting quality consistency or intellectual property security. Relying on an external supplier introduces supply chain risks, such as delivery delays, price fluctuations, or even supplier insolvency. Furthermore, effective communication and contract management become paramount to ensure the outsourced service or product meets your exact specifications and expectations.

Ultimately, the choice hinges on a thorough, multi-faceted evaluation. It’s about understanding your company’s core competencies, market dynamics, and future goals. A superficial analysis based solely on a simple price comparison can easily lead to suboptimal outcomes, highlighting why a comprehensive approach is not just beneficial, but essential for sustainable success.

Designing Your Essential Make Or Buy Decision Checklist

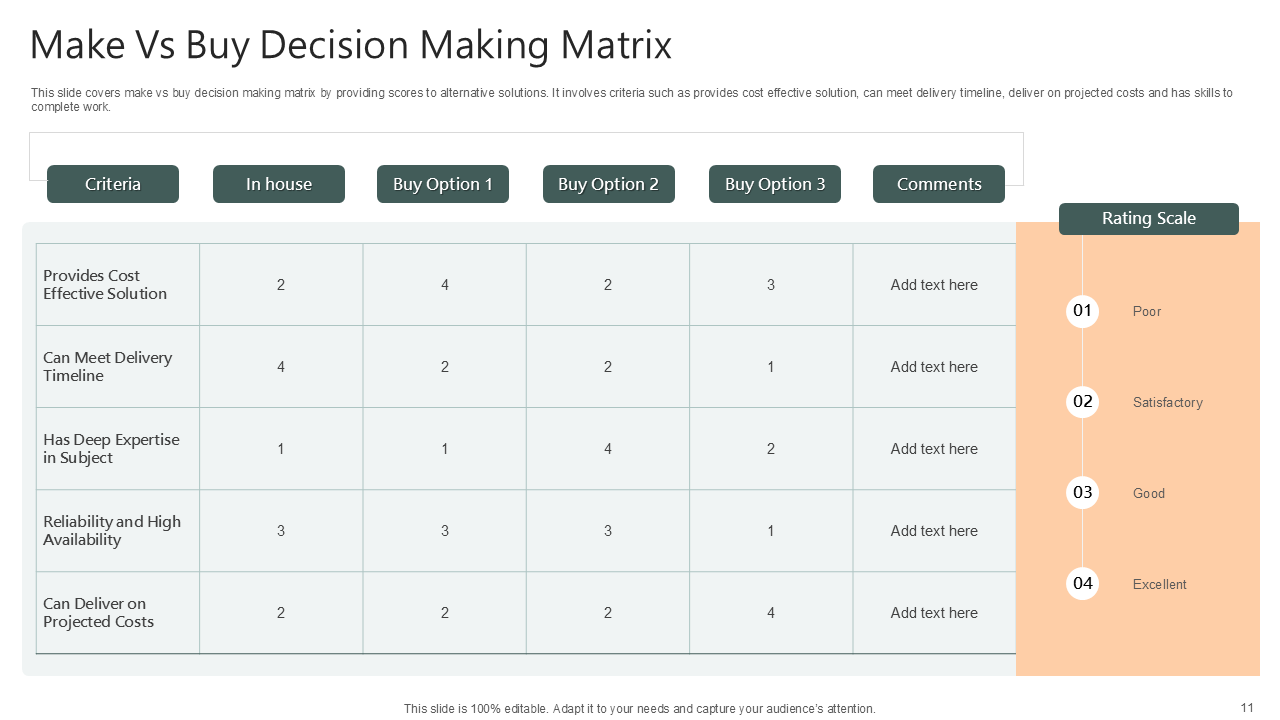

To navigate these intricate considerations, a structured approach is vital. Your make or buy decision checklist template should act as a systematic guide, ensuring no critical factor is overlooked. It helps you quantify intangible benefits and risks, fostering a more objective and defensible decision-making process within your organization.

When constructing your checklist, think broadly across several key dimensions. Here are some fundamental categories and questions to include:

- Cost Analysis

- What are the direct costs of making (labor, materials, overhead)?

- What are the indirect costs (management time, quality control, inventory holding)?

- What are the direct costs of buying (purchase price, shipping, tariffs)?

- What are the indirect costs of buying (supplier management, contract negotiation, potential communication issues)?

- What are the opportunity costs for both options (e.g., what else could internal resources be doing)?

- What is the long-term cost implication for both scenarios?

- Capacity and Capability

- Do we have the internal capacity (equipment, space, personnel) to make this?

- Do we possess the necessary expertise, skills, and technology?

- Can we meet expected demand fluctuations internally?

- Does the external supplier have the proven capacity and expertise?

- Can the external supplier reliably meet our quality and delivery requirements?

- Quality and Control

- How critical is absolute quality control for this product or service?

- Can internal production guarantee the required quality standards?

- What are the quality control mechanisms of the external supplier?

- How will we manage quality assurance with an external provider?

- Are there any intellectual property concerns with outsourcing?

- Strategic Alignment and Risk

- Is making this product or service core to our business mission and competitive advantage?

- Does outsourcing align with our long-term strategic goals?

- What are the risks associated with internal production (e.g., project delays, technological obsolescence)?

- What are the risks associated with outsourcing (e.g., supply chain disruption, dependence on a single vendor, loss of unique skills)?

- How flexible are both options to market changes and evolving needs?

Once you’ve filled out your checklist, convene relevant stakeholders from finance, operations, procurement, and even sales to review the findings. Assign scores or weights to each criterion based on its importance to your business, allowing for a quantitative comparison. This collaborative review ensures a holistic perspective and helps identify any overlooked factors, culminating in a well-reasoned decision that supports your overarching business objectives.

Embracing a systematic framework for these crucial strategic choices will undoubtedly lead to more confident and beneficial outcomes for your organization. By thoroughly evaluating every facet of the ‘make’ versus ‘buy’ equation, you empower your business to optimize resources, enhance efficiency, and build a more resilient and competitive future.

The diligence applied in completing such a comprehensive assessment goes beyond mere compliance; it becomes a cornerstone of smart business strategy. It fosters a culture of critical thinking and proactive planning, ensuring that every significant investment and operational shift is grounded in solid reasoning and contributes positively to your growth trajectory.