Keeping a fleet of vehicles running smoothly is no small feat. It involves a delicate balance of managing logistics, ensuring driver safety, and, crucially, maintaining the health of each vehicle. Neglecting maintenance can lead to costly breakdowns, unexpected delays, and even dangerous situations on the road, impacting your bottom line and reputation. A proactive approach to vehicle care is not just a best practice; it is an absolute necessity for any operation relying on its fleet.

This is where a robust and well-structured fleet vehicle maintenance checklist template comes into play. It transforms a potentially overwhelming task into a systematic, manageable process. By standardizing inspections and service schedules, you ensure consistency, reduce the risk of overlooking critical issues, and extend the lifespan of your assets. Let’s explore how to build and utilize an effective system that keeps your wheels turning safely and efficiently.

The Core Components of an Effective Fleet Maintenance Schedule

An effective fleet maintenance schedule is the backbone of any successful fleet operation. It moves beyond simply reacting to problems as they arise, instead embracing a preventive approach that identifies and addresses potential issues before they escalate. This strategy not only saves money in the long run by avoiding expensive emergency repairs but also significantly improves vehicle reliability and driver safety.

At its heart, a good maintenance schedule is about consistency and thoroughness. It dictates when specific checks and services should be performed, taking into account factors like mileage, operating hours, and elapsed time. The goal is to catch wear and tear early, replace parts before they fail, and ensure all systems are functioning optimally, thereby maximizing uptime and operational efficiency for every vehicle in your fleet.

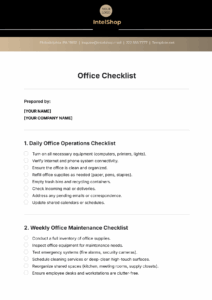

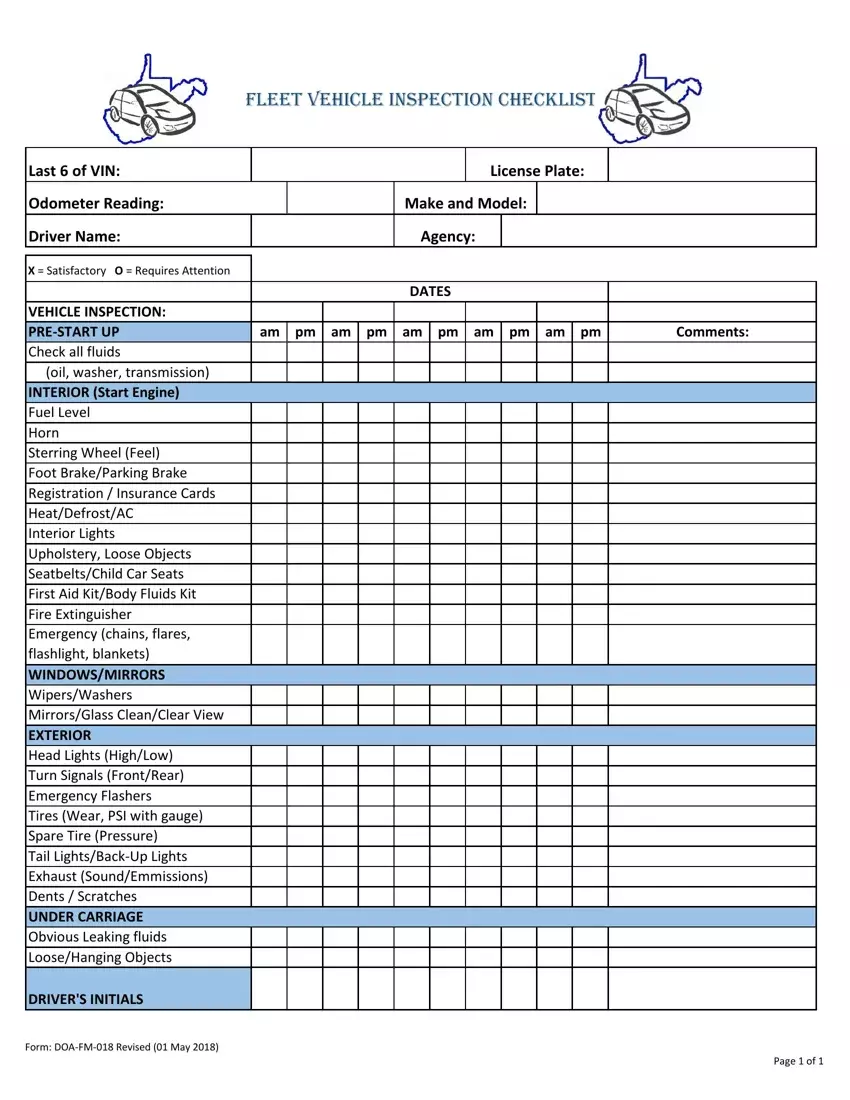

Daily Pre-Trip Inspections

The journey to a well-maintained fleet begins before the ignition is even turned. Daily pre-trip inspections are your first line of defense, empowering drivers to identify obvious issues that could impact safety or performance during their shift. These checks are quick but critical, setting the stage for a safe and productive day. Implementing a clear, easy-to-follow routine for these daily checks ensures nothing important gets missed by busy drivers.

Your daily pre-trip checklist should cover essential visual and operational checks:

- Tire condition and pressure (including spares if applicable)

- Functionality of all exterior and interior lights (headlights, brake lights, turn signals, hazard lights)

- Fluid levels (engine oil, coolant, brake fluid, windshield washer fluid)

- Brake operation (pedal feel, parking brake)

- Mirror and window cleanliness and adjustment

- Wiper blade condition and operation

- Horn functionality

- Presence and good working order of safety equipment (first aid kit, fire extinguisher, warning triangles)

Weekly and Monthly Deep Dives

Moving beyond the daily checks, your fleet maintenance schedule needs to incorporate more detailed inspections performed on a weekly or monthly basis, depending on vehicle usage and type. These deeper dives allow mechanics or trained personnel to assess components that aren’t typically part of a quick pre-trip check. This regular, thorough scrutiny helps in identifying more subtle signs of wear that could lead to significant problems if left unaddressed.

This level of inspection might involve:

- Comprehensive fluid level and condition checks (including transmission and differential fluids)

- Inspection of belts and hoses for cracks, fraying, or leaks

- Checking battery terminals for corrosion and charge level

- Inspecting exhaust systems for damage or leaks

- Reviewing suspension components for looseness or damage

- Checking brake pad and rotor wear more closely

- Lubricating chassis components as per manufacturer recommendations

By systematically working through these lists, you build a comprehensive picture of each vehicle’s health, allowing for predictive maintenance rather than reactive repairs. This foresight is invaluable for managing costs and maintaining service delivery.

Customizing Your Fleet Vehicle Maintenance Checklist Template for Success

While a generic fleet vehicle maintenance checklist template provides a solid starting point, true efficiency comes from customizing it to fit your specific operational needs. Every fleet is unique, whether it’s the types of vehicles you operate, the environments they traverse, or the demands placed upon them. A template designed for a long-haul trucking company, for instance, might not be perfectly suited for a local delivery service, and vice-versa.

Consider the diverse range of vehicles in your fleet. Are you managing light-duty vans, heavy-duty trucks, specialized equipment, or a mix of everything? Each vehicle type comes with its own set of maintenance requirements and manufacturer recommendations. The operating conditions also play a huge role; vehicles consistently driven in dusty environments, extreme temperatures, or stop-and-go city traffic will experience different wear patterns compared to those on open highways.

The key to effective customization involves a collaborative approach. Engage your drivers, technicians, and even operations managers in the process. Drivers can offer invaluable insights into recurring issues they observe or report during their daily duties. Technicians can advise on common failure points for specific vehicle models or components they frequently repair. This feedback loop ensures that your fleet vehicle maintenance checklist template is not just a theoretical document but a practical tool that reflects real-world conditions.

Regular review and refinement are also crucial. Your fleet operations aren’t static; they evolve. New vehicles might be added, routes could change, or regulatory requirements might shift. Your maintenance checklist should be a living document, updated periodically to reflect these changes. By treating your checklist as an adaptable tool, you ensure it remains relevant and maximally effective in preserving the reliability and longevity of your valuable fleet assets.

- Specific vehicle models and their manufacturer-recommended service intervals

- Operational environment (e.g., city driving, off-road, long-haul, cold weather)

- Feedback from drivers and maintenance personnel on common issues or critical checks

- Regulatory compliance and industry-specific safety standards

Implementing a detailed and tailored maintenance schedule is one of the smartest investments a fleet manager can make. It protects your assets, ensures driver safety, and maintains your operational reputation, ultimately contributing to a healthier bottom line. Embracing a proactive maintenance culture, supported by a robust checklist system, sets the stage for long-term success and seamless operations.