In the bustling world of construction, manufacturing, logistics, or even just a busy office, equipment is the backbone of daily operations. From heavy machinery to simpler tools, keeping these assets in top working order isn’t just a good idea, it’s absolutely critical for safety, efficiency, and longevity. Ignoring the tell-tale signs of wear and tear or potential malfunction can lead to costly downtime, expensive repairs, and, most importantly, dangerous accidents.

That’s where a structured approach comes in, offering peace of mind and proactive management. Imagine having a simple, systematic way to ensure everything is running smoothly before a busy day even begins. This isn’t just a dream; it’s a tangible reality made possible by a well-designed daily equipment inspection checklist template. It’s your first line of defense, a routine safeguard that empowers your team to identify issues early, prevent failures, and maintain a safer, more productive environment.

Why a Daily Equipment Inspection Checklist Template is a Game-Changer

Adopting a daily equipment inspection checklist template transforms reactive maintenance into proactive asset management. It’s not merely a piece of paper or a digital form; it’s a strategic tool that embeds safety and efficiency into your daily workflow. Think about it: a small investment of time each morning can save hours of repairs, thousands in replacement costs, and potentially even lives. This template acts as a standardized guide, ensuring that every critical point is checked, every time, regardless of who is performing the inspection. It removes guesswork and introduces a level of consistency that is hard to achieve otherwise.

Enhancing Workplace Safety

The most compelling reason to implement a daily inspection routine is undoubtedly safety. Faulty equipment is a leading cause of workplace injuries and accidents. A checklist forces a systematic look at all safety-critical components, from brakes and emergency stops to guards and warning lights. By catching defects like frayed cables, loose fittings, or leaking fluids before operation, you significantly reduce the risk of incidents. This proactive approach fosters a culture of safety, making every operator aware of their responsibility in preventing harm.

Extending Equipment Lifespan and Reducing Downtime

Regular inspections help in identifying minor issues before they escalate into major problems. A slightly worn component, a low fluid level, or an unusual noise can be flagged and addressed promptly. This preventive maintenance approach extends the overall lifespan of your equipment, delaying the need for costly replacements. Furthermore, by nipping problems in the bud, you drastically reduce unexpected breakdowns, which are notorious for causing significant operational downtime and disrupting project schedules. Consistency is key here; a daily equipment inspection checklist template ensures that no critical check is ever missed.

Boosting Operational Efficiency and Compliance

When equipment is well-maintained and operating optimally, your team can work more efficiently. There are fewer interruptions, less frustration, and a smoother flow of work. Operators can focus on their tasks with confidence, knowing their tools are reliable. Beyond efficiency, many industries are subject to strict regulatory requirements regarding equipment maintenance and safety. A detailed daily inspection record provides invaluable documentation, demonstrating compliance during audits and potentially reducing insurance premiums. It shows due diligence, protecting your organization from potential liabilities.

Crafting Your Effective Daily Equipment Inspection Checklist Template

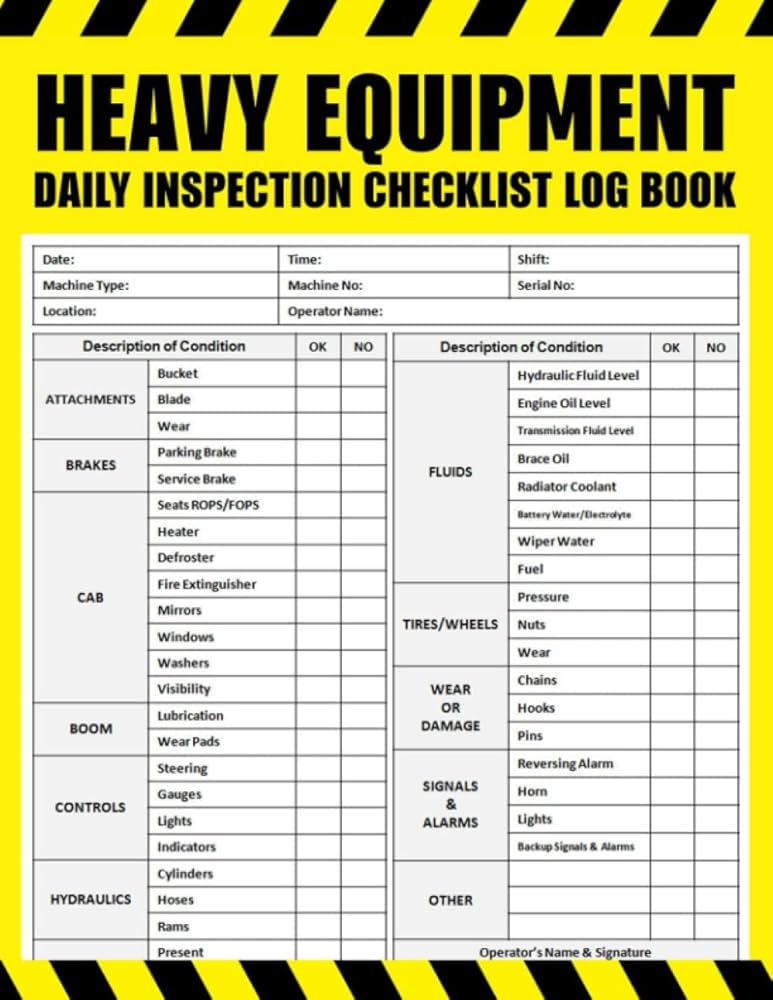

Creating an effective daily equipment inspection checklist template isn’t about simply listing a few items; it’s about tailoring it to your specific equipment, industry, and operational needs. The goal is to make it comprehensive enough to cover all critical aspects, yet simple enough to be completed quickly and consistently. Begin by categorizing your equipment types – heavy machinery will have different points than office equipment or specialized tools. Each category should then have its own specific template or a section within a broader one.

Start by identifying all safety-critical components, followed by operational and performance checks. Think about what typically goes wrong, what needs regular attention, and what could cause a major failure. It’s often helpful to involve the operators themselves in this process, as they have firsthand experience with the equipment’s nuances and common issues. Their insights can be invaluable in ensuring the checklist is practical and thorough.

Consider including the following essential elements in your template:

- Equipment Identification: Clearly state the equipment name, model, serial number, and location.

- Date and Time of Inspection: Essential for record-keeping and tracking.

- Inspector’s Name and Signature: Accountability is key.

- Specific Inspection Points: Break these down into manageable categories (e.g., "Visual Checks," "Functional Checks," "Fluid Levels").

- Pass/Fail or OK/Not OK Columns: Simple response options for quick completion.

- Notes/Actions Required Section: Space to elaborate on any issues found and what steps need to be taken.

- Follow-Up Action Confirmation: A section to confirm that issues were addressed.

Once you have a draft, test it out. Have several different operators use it for a week or two and gather their feedback. Is anything missing? Is it too long or too short? Is anything unclear? Refine the template based on these insights until it truly serves its purpose. Remember, this isn’t a static document; it should be reviewed periodically, perhaps annually, or whenever new equipment is introduced or regulations change, to ensure it remains relevant and effective.

Embracing a systematic approach to equipment checks through a well-designed template is a small change that yields massive returns. It’s about empowering your team, safeguarding your assets, and ensuring a smoother, safer operational flow every single day. By prioritizing daily inspections, you’re not just preventing problems; you’re actively building a more resilient and responsible work environment for everyone involved.