Ensuring the safe operation of heavy machinery like overhead cranes is paramount in any industrial setting. If you’re managing a facility that relies on these powerful pieces of equipment, you’re probably aware that regular maintenance and thorough inspections aren’t just good practice; they’re essential for preventing accidents, ensuring operational efficiency, and complying with safety regulations. That’s precisely why having a reliable and comprehensive overhead crane inspection checklist template is not just helpful, but absolutely critical for maintaining a secure and productive work environment.

Overhead cranes, while robust, are complex systems with numerous components that can wear down or malfunction over time. From the hooks and wire ropes to the electrical systems and structural integrity, every part plays a vital role in its safe functioning. Neglecting even a small detail during an inspection could lead to costly downtime, equipment damage, or, most importantly, serious injuries to personnel.

This article will walk you through the importance of diligent crane inspections and provide insights into what makes an effective inspection template. By understanding the key areas to focus on and adopting a systematic approach, you can significantly enhance workplace safety and extend the lifespan of your valuable lifting equipment.

The Indispensable Role of Regular Crane Inspections in Workplace Safety

The continuous safe operation of overhead cranes isn’t something that happens by chance; it’s the direct result of a proactive and rigorous inspection program. Beyond just a legal obligation, regular inspections are a foundational pillar of a robust safety culture, ensuring that potential issues are identified and addressed long before they escalate into critical failures. It’s about more than just avoiding fines; it’s about protecting lives and investments.

Imagine the stress and potential fallout from an unexpected crane malfunction. Production grinds to a halt, emergency protocols kick in, and investigations begin. All of this can be significantly mitigated, if not entirely prevented, through diligent, routine checks. These inspections provide a snapshot of the crane’s health, allowing for predictive maintenance and timely repairs, which ultimately contribute to smoother operations and greater peace of mind.

Understanding Different Inspection Frequencies

Not all inspections are created equal, nor are they performed with the same frequency. Industry standards and regulatory bodies, such as OSHA and ASME, typically categorize inspections into different levels based on their depth and timing.

Daily Pre-Shift Checks

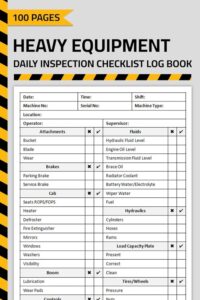

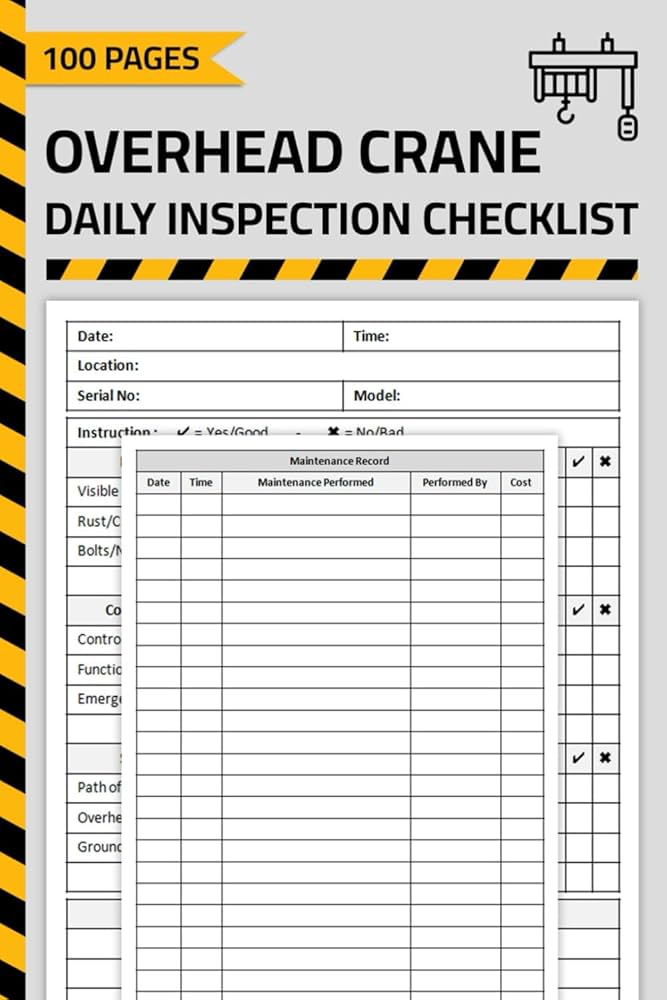

These are quick, visual inspections performed by the crane operator before each shift or daily use. They are designed to catch obvious and immediate hazards. Things like checking for obstructions, verifying control functionality, observing for unusual noises, and a quick look at the hook and hoist rope condition are typically part of this routine. It’s a fundamental step that empowers the operator to be the first line of defense against potential issues.

Frequent Inspections

More detailed than a pre-shift check, frequent inspections are generally conducted monthly to quarterly, depending on the crane’s service class and the severity of its operating conditions. These inspections delve deeper into critical components, looking for signs of wear, deformation, cracks, or damage in components like hooks, wire rope, sheaves, brakes, and limit switches. The findings from these inspections are usually documented, ensuring a continuous record of the crane’s condition.

Periodic Inspections

These are the most comprehensive inspections, typically performed annually or every 12 months, though this can vary. Periodic inspections involve a thorough examination of all crane components, including structural members, electrical systems, mechanical parts, and safety devices. Often, these inspections require the crane to be taken out of service for a short period. They often involve non-destructive testing (NDT) methods for critical load-bearing components and are usually conducted by a qualified and certified inspector. This is where an overhead crane inspection checklist template becomes an invaluable tool, ensuring no stone is left unturned and every detail is meticulously recorded.

By maintaining these different levels of inspection, you build a comprehensive safety net around your overhead crane operations. Each layer reinforces the others, contributing to a holistic approach to equipment management and workplace safety.

Building Your Own Comprehensive Inspection Checklist

When it comes to crafting an effective inspection checklist, remember that while templates provide an excellent starting point, customization is key. Every facility, every crane, and every operational environment has unique aspects that should be reflected in your inspection protocol. Think of a generic template as a robust skeleton, and your specific operational details as the muscle and sinew that bring it to life, ensuring it perfectly fits your needs.

A well-designed checklist doesn’t just list items; it guides the inspector through a systematic process, ensuring consistency and thoroughness. It should be clear, easy to understand, and provide sufficient space for detailed observations and corrective actions. The goal is not just to check boxes, but to foster a deeper understanding of the crane’s condition at every inspection point.

So, what are the essential elements you should consider incorporating into your own robust overhead crane inspection checklist template? Here’s a breakdown of key areas that should always be covered, regardless of the specific crane model or industry.

- Hoists and Ropes/Chains: Inspect for wear, fraying, broken strands, corrosion, proper lubrication, and secure attachments. Check the hoist mechanism for smooth operation and unusual noises.

- Hooks: Examine for deformation, cracks, gouges, wear on the saddle or throat, and proper latch functionality.

- Brakes: Verify brake effectiveness for hoist and travel motions, checking for proper stopping distance and smooth operation without excessive slippage.

- Runways and Rails: Look for signs of wear, damage, misalignment, cracks, and secure fastening. Ensure the area below is clear of obstructions.

- Electrical Components: Inspect wiring for damage, proper insulation, and secure connections. Check control panels, buttons, and emergency stops for functionality.

- Controls and Safety Devices: Test all control functions (hoist, traverse, travel) and verify the proper operation of limit switches, overload protection, and anti-collision systems.

- Structural Components: Examine girders, end trucks, and other load-bearing structures for cracks, deformation, corrosion, loose bolts, or weld integrity.

- Warning Devices: Ensure horns, lights, and other warning indicators are operational and clearly audible/visible.

Adopting a detailed inspection methodology, supported by a well-structured template, transforms the often-daunting task of crane maintenance into a manageable, systematic process. It empowers your team to identify and rectify potential hazards proactively, significantly reducing the likelihood of unexpected failures and promoting a consistently safe working environment. By consistently implementing these checks and meticulously documenting the findings, you not only ensure compliance with safety standards but also contribute to the extended operational life and reliability of your valuable equipment.