Bringing new equipment online is a critical phase for any operation, requiring meticulous planning and execution to ensure everything runs smoothly from day one. A well-structured new equipment commissioning checklist template is an indispensable tool that guides your team through every step, minimizing errors, enhancing safety, and optimizing performance right from the start. It transforms a potentially chaotic process into a streamlined, repeatable workflow, guaranteeing that your investment pays off without unexpected hiccups.

Without a systematic approach, the introduction of new machinery can lead to costly delays, premature wear and tear, and even safety hazards. Imagine the frustration of discovering a crucial component wasn’t properly calibrated weeks after installation, impacting productivity and requiring unscheduled downtime. This is precisely why a comprehensive commissioning process isn’t just a good idea; it’s a fundamental requirement for operational excellence and longevity.

This guide aims to demystify the commissioning process and underscore the immense value of having a robust template in place. We’ll explore the various stages involved, the key considerations at each juncture, and how a well-thought-out checklist can serve as your roadmap to a successful equipment launch, ensuring your new assets contribute positively to your bottom line from the moment they are powered on.

Understanding the Core Stages of Equipment Commissioning

The commissioning of new equipment is far more than just plugging it in and flipping a switch. It’s a systematic process that validates the equipment’s functionality, performance, and compliance with specifications before it’s integrated into live operations. This multi-faceted journey ensures that every component works in harmony and that the system as a whole meets its intended purpose. Skipping steps here can lead to cascading problems down the line, making a thorough approach absolutely essential.

Pre-Installation and Planning

Before any physical equipment arrives, a significant amount of groundwork needs to be covered. This initial phase involves reviewing technical specifications, ensuring site readiness, and coordinating with vendors. It includes checking power requirements, environmental conditions like temperature and humidity, and verifying that the installation space is clear and accessible. Adequate planning at this stage can prevent major headaches and delays later on, setting the foundation for a smooth installation.

Physical Installation and Setup

Once the equipment is on site, the next step is its physical installation. This involves unpacking, assembling, and securing the machinery according to the manufacturer’s guidelines. Critical aspects here include ensuring all mechanical connections are tight, hydraulic lines are correctly routed, and pneumatic systems are leak-free. Proper installation is fundamental to the equipment’s stability and operational integrity.

Initial Power-Up and Safety Verifications

With the physical installation complete, the equipment can be powered on for the first time. This phase is heavily focused on safety. Before energizing, all safety interlocks, emergency stop buttons, and guarding systems must be thoroughly checked to ensure they are functional and correctly installed. The initial power-up is often a controlled process, observing for any unusual noises, smells, or indications of malfunction.

Comprehensive Functional Testing

Once safely powered, the equipment undergoes functional testing. This means operating the equipment through all its intended modes and cycles without any load or materials. Testers will verify that all buttons, sensors, motors, and automated sequences respond as expected. Each individual function is tested to ensure it operates within its design parameters and communicates correctly with other integrated systems.

Performance Validation and Optimization

Following successful functional tests, the equipment is put through performance validation, often with actual production materials or under simulated operational loads. This stage aims to confirm that the equipment meets specified output, quality, and efficiency targets. Adjustments and fine-tuning may be necessary to optimize performance, calibrate sensors, and ensure the equipment operates at its peak capacity.

Documentation, Training, and Handover

The final stages involve comprehensive documentation of all test results, settings, and configurations. Operational manuals are reviewed, and maintenance schedules are established. Crucially, the operating and maintenance staff must receive thorough training on the new equipment. Once all checks are verified, and training is complete, the equipment is formally handed over for operational use, marking the successful completion of the commissioning process.

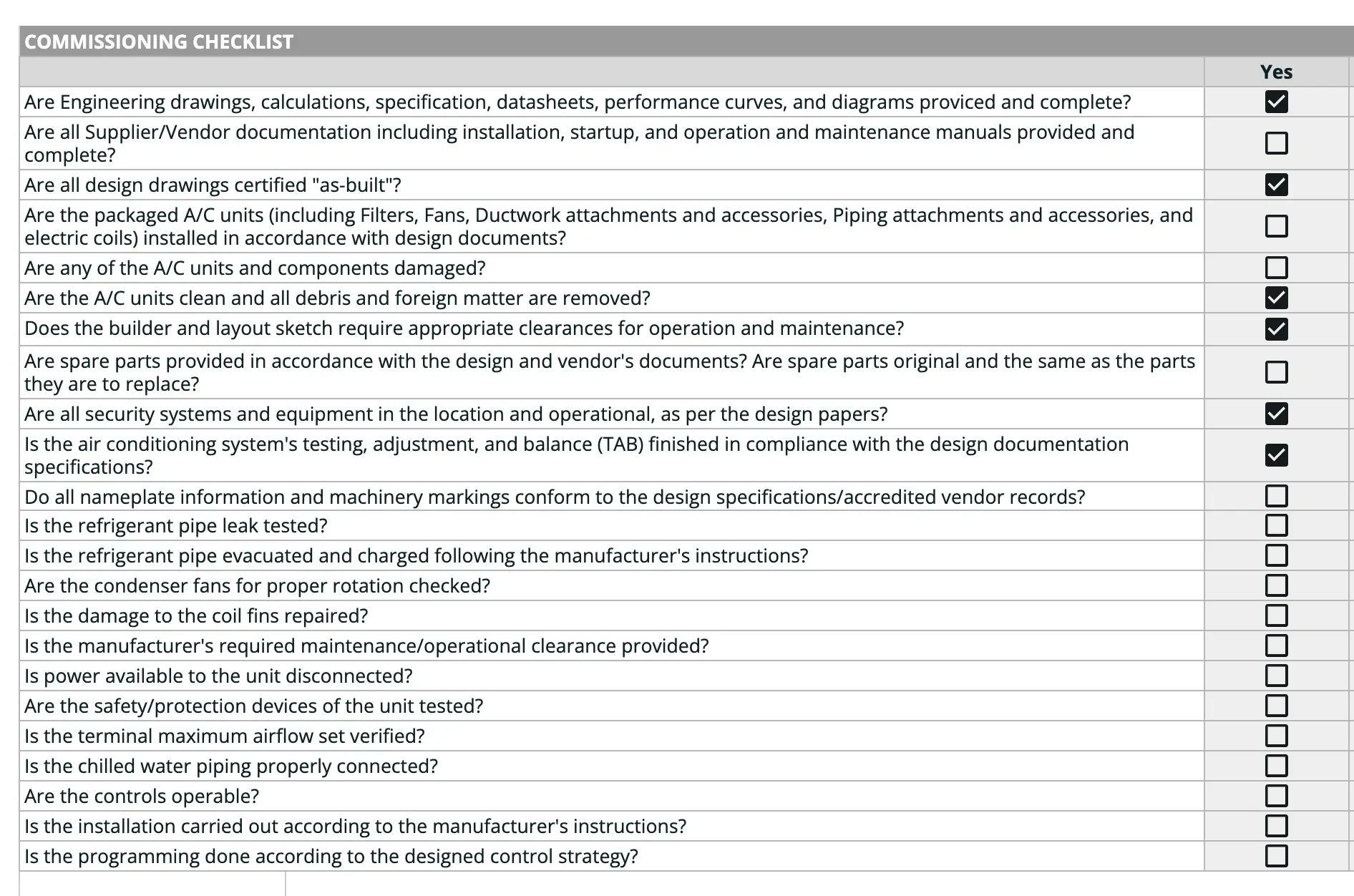

Crafting Your Own Effective Commissioning Checklist

While the core principles of commissioning remain consistent, the specifics of a checklist will vary greatly depending on the type and complexity of the new equipment. A generic checklist might provide a starting point, but a truly effective one needs to be tailored to your specific machinery, industry standards, and internal protocols. This customization ensures that every relevant detail is covered, leaving no stone unturned in your pursuit of flawless operation.

The beauty of a well-designed new equipment commissioning checklist template lies in its adaptability. It serves as a living document that can be refined over time, incorporating lessons learned from previous installations and evolving industry best practices. Think of it as a comprehensive guide that not only ensures compliance but also fosters a culture of thoroughness and accountability within your team.

Here are some key elements you’ll want to include and consider when building out your own template:

- Pre-Arrival and Site Readiness Checks: Verify space, utilities, access, and environmental conditions.

- Mechanical Installation Verification: Confirm proper assembly, alignment, lubrication, and secure fastening.

- Electrical and Control Systems: Check wiring, power supply, grounding, emergency stops, and sensor calibration.

- Software and Network Configuration: Ensure correct program loading, network connectivity, and parameter settings.

- Safety Feature Validation: Test all guards, interlocks, light curtains, and warning systems.

- Operational and Performance Testing: Run through various modes, test with materials, and measure output against specifications.

- Documentation and Training: Confirm receipt of manuals, warranty information, and completion of operator training.

- Sign-Off and Handover: Formal acceptance by relevant stakeholders, signaling readiness for production.

Regularly reviewing and updating your checklist will help maintain its relevance and effectiveness, ensuring it continues to serve as an invaluable asset for every new equipment deployment.

Implementing a structured commissioning process, guided by a well-developed checklist, is not merely a procedural step; it’s a strategic investment in the longevity and efficiency of your assets. It provides peace of mind, knowing that your new machinery is not only installed correctly but is also optimized for performance and safety from day one. This proactive approach significantly reduces the likelihood of costly downtime, extends equipment lifespan, and ultimately contributes to a more productive and profitable operation.

Embracing this methodical approach ensures that your organization is always prepared for the successful integration of new technology, fostering a culture of precision and operational excellence. By making a comprehensive commissioning checklist a standard part of your workflow, you’re setting the stage for consistent success and maximizing the return on your equipment investments.