Maintaining your valuable tools and equipment isn’t just a good idea, it’s absolutely essential for safety, efficiency, and longevity. Without a structured approach, it’s easy to overlook crucial steps, leading to unexpected breakdowns, costly repairs, and even dangerous situations. That’s why having a reliable tool equipment maintenance checklist template at your fingertips can make all the difference, transforming a haphazard process into a streamlined, proactive system.

Think about the investment you’ve made in your tools, whether for a professional workshop, a construction business, or even your serious home DIY projects. These aren’t just objects; they’re instruments that help you achieve your goals and generate income. Neglecting their care is akin to throwing money away, as poorly maintained equipment underperforms, wears out faster, and consumes more energy.

This article will guide you through understanding the critical importance of a robust maintenance strategy and how to effectively utilize and even create your own personalized checklist templates. By implementing a systematic approach, you’ll ensure your equipment operates at its peak, remains safe for use, and serves you reliably for years to come.

Why a Solid Maintenance Plan is Your Best Investment

Every piece of equipment, from the simplest hand tool to the most complex machinery, experiences wear and tear over time. This is an unavoidable fact of mechanical existence. However, the rate and severity of that wear are largely within your control through diligent maintenance. A solid maintenance plan isn’t an expense; it’s a profound investment that pays dividends in multiple ways, ensuring your operations run smoothly and safely.

The most immediate benefit of a well-executed maintenance plan is enhanced safety. Tools that are regularly inspected, cleaned, and repaired are far less likely to malfunction or cause accidents. Worn components, loose connections, or dulled blades can pose significant risks to operators. Proactive checks identify these hazards before they escalate, protecting you and anyone else using the equipment from injury. Safety should always be paramount, and maintenance is a cornerstone of a safe working environment.

Beyond safety, a strong maintenance regimen dramatically extends the lifespan of your tools. Just like a car needs oil changes and tire rotations to keep running, your power tools and machinery require regular attention. Lubricating moving parts, tightening fasteners, and replacing minor worn components prevent catastrophic failures that could render an expensive piece of equipment useless prematurely. This translates directly into significant cost savings over time, as you avoid the frequent need for replacements.

Financial benefits also stem from reduced downtime. When a critical piece of equipment breaks down unexpectedly, it can halt an entire project, costing not only repair money but also lost productivity and potential missed deadlines. Scheduled maintenance allows you to address potential issues during planned downtime, minimizing disruptions and keeping your projects on track and within budget. It’s about preventing a small problem from spiraling into a major operational headache.

The Power of Proactive vs. Reactive Approaches

Many people operate on a reactive maintenance model: fix it when it breaks. While sometimes unavoidable, this approach is inherently inefficient and costly. Proactive maintenance, on the other hand, involves regularly inspecting and servicing equipment to prevent failures from occurring in the first place. It’s about being one step ahead, identifying potential problems before they manifest as full-blown breakdowns. This strategy allows for controlled repairs and replacements, often during off-peak hours, rather than emergency interventions that can be rushed and more expensive.

Furthermore, properly maintained tools perform better. Clean components, sharp blades, and well-calibrated settings ensure that your equipment delivers consistent, high-quality results. This improved performance can lead to better craftsmanship, faster completion times, and a higher standard of work overall. When your tools are in top shape, so is your output, fostering a reputation for reliability and quality.

Ultimately, a robust maintenance strategy provides peace of mind. Knowing that your equipment is in excellent working order allows you to focus on your tasks without the constant worry of breakdowns or safety hazards. This sense of security is invaluable, enabling you to work more confidently and efficiently, maximizing your productivity and satisfaction. It’s the assurance that your tools are ready for whatever job comes next.

Building Your Own Effective Tool Equipment Checklist

Creating a custom checklist is incredibly empowering because it tailors the maintenance process to your specific tools and usage patterns. While a general tool equipment maintenance checklist template offers a fantastic starting point, personalizing it ensures that every critical aspect of *your* equipment is addressed. The goal is to develop a clear, actionable guide that makes routine care straightforward and consistent, no matter who is performing the check.

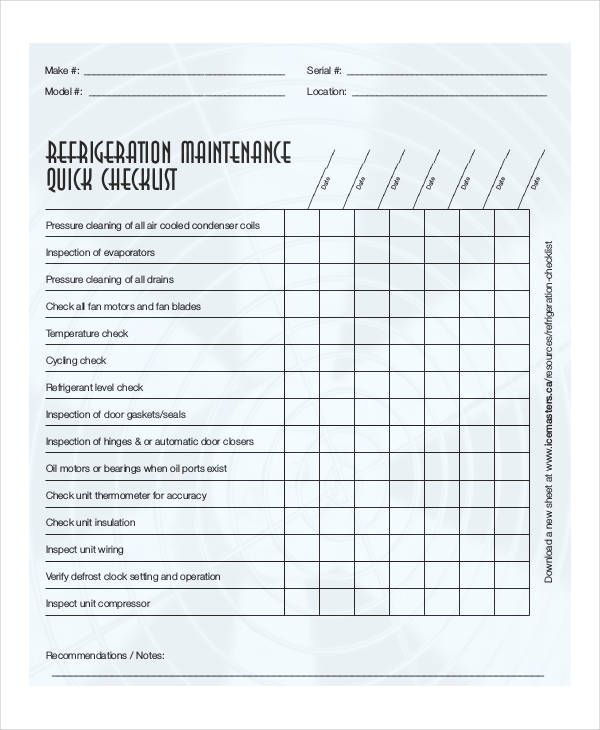

Start by categorizing your tools. Hand tools, power tools, workshop machinery, and specialized equipment will all have different maintenance needs. For each category, list the key items that require regular attention. This might include checking for loose parts, looking for frayed cords, inspecting blades for sharpness, or ensuring proper lubrication points are addressed. The more detailed you are in this initial phase, the more comprehensive your eventual checklist will be.

Consider the frequency of maintenance for each item. Some checks might be daily, like cleaning a saw after use, while others could be weekly, monthly, or even annually, such as a deep clean of a compressor or professional calibration of sensitive instruments. Integrating these frequencies directly into your checklist helps create a practical schedule that can be easily followed. Regularity is key, so breaking down tasks into manageable timeframes is crucial for success.

Here’s a breakdown of common elements you might include:

- Visual Inspection for Damage: Check for cracks, dents, corrosion, or any unusual wear on housings, cables, and attachments.

- Cleaning and Debris Removal: Wipe down surfaces, clear vents, and remove sawdust, grime, or other buildup that can hinder performance or cause overheating.

- Lubrication of Moving Parts: Apply appropriate lubricants to gears, bearings, and pivots according to manufacturer specifications to reduce friction and wear.

- Checking Fasteners and Connections: Ensure all screws, bolts, and clamps are tight. Inspect electrical cords and plugs for damage or loose connections.

- Blade and Bit Condition: Verify that blades are sharp, bits are intact, and abrasive surfaces are not excessively worn. Replace or sharpen as needed.

- Safety Feature Verification: Test safety guards, emergency stops, and other protective mechanisms to ensure they are fully functional.

- Storage and Environment Check: Confirm tools are stored in a dry, clean, and secure environment, protecting them from rust, dust, and unauthorized use.

- Performance Testing: Briefly operate the tool to listen for unusual noises or vibrations, and observe its functionality.

- Documentation: Record the date of maintenance, what was done, and any issues found. This creates a valuable history for each tool.

Taking the time to implement a structured maintenance plan, supported by a well-designed checklist, is a decision you will never regret. It’s about building a culture of care around your valuable assets, ensuring they are always ready for the next challenge. This proactive approach not only safeguards your investment but also enhances the overall safety and efficiency of your work environment, leading to greater productivity and peace of mind.