If you’re running a busy kitchen, you know that keeping everything running smoothly is paramount. From the sizzling grill to the humming refrigeration units, every piece of equipment plays a critical role in your daily operations. That’s why having a robust restaurant equipment maintenance checklist template isn’t just a good idea; it’s essential for your operation’s success and longevity.

Imagine the chaos of a walk-in freezer failing during peak service, or an oven refusing to heat up when you have a full house. These aren’t just minor inconveniences; they can lead to significant financial losses, spoiled food, unhappy customers, and a mad rush for emergency repairs. Proactive maintenance is your best defense against such scenarios, transforming potential disasters into manageable routines.

This guide will walk you through the importance of regular equipment upkeep and help you understand how a structured approach can save you time, money, and a lot of stress. We’ll explore the benefits and practical steps to ensure your kitchen machinery remains in top working condition, day in and day out.

Why a Regular Maintenance Schedule is Your Kitchen’s Best Friend

Implementing a consistent maintenance schedule for your restaurant equipment is one of the smartest investments you can make for your business. It shifts your approach from reactive repairs to proactive prevention, offering a multitude of benefits that directly impact your bottom line and your kitchen’s efficiency. Think of it as preventative care for your most valuable assets.

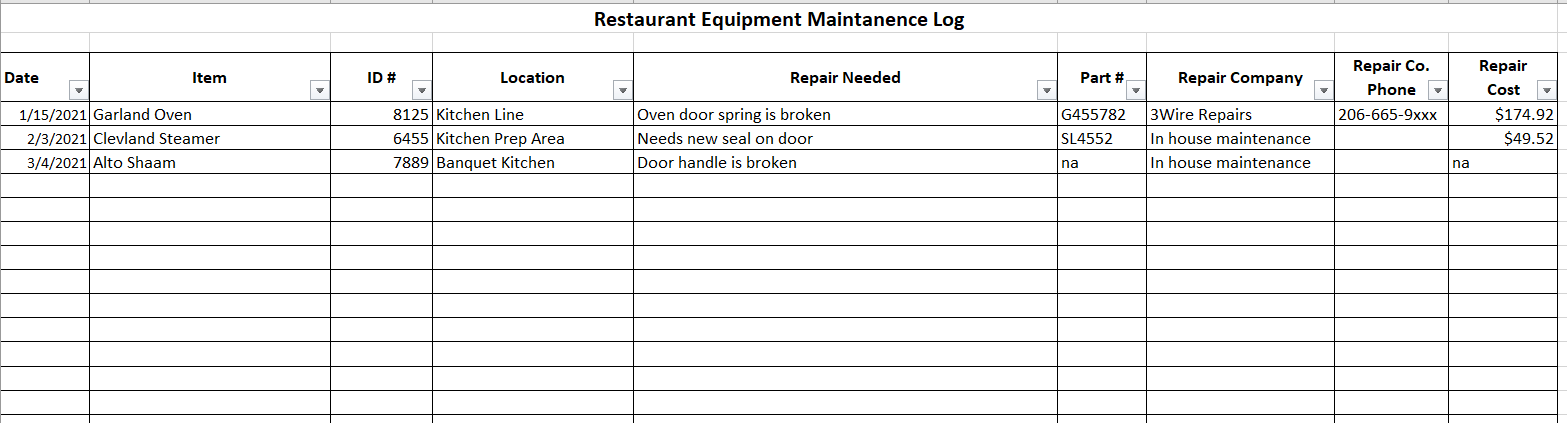

One of the most immediate advantages is the prevention of costly breakdowns and emergency repairs. When an oven or a fryer suddenly stops working, you’re not just looking at repair costs, but also potential lost revenue from downtime, wasted ingredients, and even compensation for staff who can’t perform their duties. Regular checks can spot minor issues before they escalate into major, expensive problems, allowing for planned, less disruptive repairs.

Beyond just preventing immediate failure, good maintenance significantly extends the lifespan of your equipment. Just like a car needs oil changes and tune-ups to last longer, your commercial kitchen equipment benefits from routine cleaning, lubrication, and inspection. This means you won’t have to replace expensive machinery as frequently, saving capital expenditure and ensuring you get the maximum value out of your initial investment.

Food safety and compliance are also critically linked to equipment maintenance. Malfunctioning refrigerators or ovens can lead to improper food temperatures, creating health hazards and potential regulatory fines. A well-maintained kitchen ensures your equipment operates within safe parameters, protecting your customers and your business’s reputation. It also helps you stay compliant with local health department regulations, making inspections a breeze rather than a source of anxiety.

Furthermore, efficient equipment operation translates directly into consistent food quality and better energy efficiency. A dirty oven or a faulty refrigeration seal can consume more energy to achieve the desired results, driving up your utility bills. Properly functioning equipment works as intended, cooking food evenly and keeping perishables at optimal temperatures, which supports your menu’s integrity and reduces waste.

Finally, a culture of maintenance empowers your staff. When employees are trained on basic daily checks and understand the importance of reporting issues, they become an integral part of your preventative strategy. This not only lightens the load on management but also fosters a sense of ownership and responsibility among the team, leading to a smoother, more harmonious kitchen environment.

Daily Quick Checks to Keep Things Humming

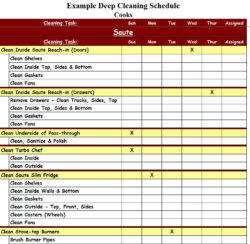

Daily checks are the first line of defense against unexpected issues. These are quick, visual inspections and simple cleaning tasks that can be performed by staff at the beginning or end of each shift. They don’t require specialized skills but are crucial for catching minor problems before they escalate.

Examples include wiping down surfaces, checking temperature gauges on refrigerators and freezers, inspecting door seals for damage, clearing drain lines, and ensuring ventilation hoods are free of grease buildup. These small actions contribute significantly to overall cleanliness and operational reliability.

Weekly and Monthly Deep Dives

While daily tasks are about immediate functionality, weekly and monthly maintenance involves deeper cleaning and more thorough inspections. These might require a bit more time but are essential for long-term equipment health.

This could mean deep cleaning fryers, descaling coffee machines, calibrating thermometers, checking belts and hoses on dishwashers, or inspecting electrical cords for wear and tear. Scheduling these tasks ensures that no critical component is overlooked, preserving the efficiency and safety of your entire kitchen.

Building Your Own Restaurant Equipment Maintenance Checklist

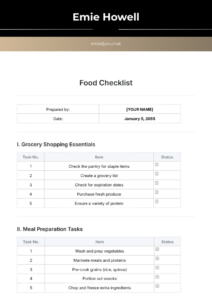

Creating a customized maintenance plan is key to truly leveraging the benefits of proactive care. While a general restaurant equipment maintenance checklist template can provide a great starting point, tailoring it to your specific kitchen layout, equipment brands, and operational demands will yield the best results. Think about the unique challenges and requirements of your establishment.

Start by inventorying all your kitchen equipment. Categorize each item by type, such as refrigeration, cooking, warewashing, and food prep. For each piece, identify critical components that require regular attention. Consult the manufacturer’s manual for recommended maintenance procedures and schedules, as these often contain specific guidance that is invaluable.

Once you have your inventory, begin populating your checklist. Assign frequencies for each task – daily, weekly, monthly, quarterly, or annually. Make sure to include details like what needs to be done, who is responsible, and what tools or cleaning supplies are required. Clear instructions reduce ambiguity and ensure tasks are completed correctly.

Here are some categories and items to consider for your personalized checklist:

- Refrigeration Units (Walk-ins, Reach-ins, Prep Tables):

- Clean condenser coils

- Check door gaskets for proper seal

- Verify temperature settings and calibrate thermometers

- Clean interior and exterior surfaces

- Inspect drain lines for clogs

- Cooking Equipment (Ovens, Grills, Fryers, Ranges):

- Deep clean and degrease surfaces

- Check burner igniters and heating elements

- Clean exhaust hood filters

- Calibrate thermostats

- Inspect gas lines for leaks (professional inspection annually)

- Warewashing (Dishwashers):

- Clean spray arms and filters

- Check detergent and rinse aid levels

- Descaling cycles as needed

- Inspect seals and hoses

- Monitor water temperature and pressure

- Food Preparation (Slicers, Mixers, Processors):

- Sanitize all contact surfaces

- Inspect blades for sharpness and damage

- Lubricate moving parts

- Check electrical cords and switches

By systematically addressing the upkeep of each piece of equipment, you foster a more reliable and efficient kitchen operation. This dedicated approach not only prevents costly surprises but also creates a safer and more productive environment for your staff. Embracing regular maintenance is a clear path to long-term success and peace of mind for any restaurant owner or manager.