Maintaining machinery and equipment is crucial for any operation, whether you are running a large manufacturing plant or a small workshop. It is not just about keeping things running smoothly; it is fundamentally about ensuring the safety of your personnel, maximizing efficiency, and extending the lifespan of your valuable assets. Neglecting regular inspections can lead to unexpected breakdowns, costly repairs, and, worst of all, serious accidents that put lives at risk.

This is where a robust and well-structured machine equipment inspection checklist template comes into play. It transforms a potentially overwhelming task into a systematic, manageable process. Instead of guessing what to check or relying solely on memory, a comprehensive checklist provides a clear roadmap, ensuring that no critical component or safety measure is overlooked. It is your ultimate tool for proactive maintenance and operational excellence.

Why a Robust Machine Equipment Inspection Checklist Template is Non-Negotiable

Implementing a systematic approach to equipment inspection through a detailed checklist offers a multitude of benefits that resonate across all aspects of your operation. Primarily, it is an investment in safety. Regular, documented checks dramatically reduce the likelihood of equipment failure due to wear and tear, faulty parts, or operator error, thereby safeguarding your workforce from potential hazards. Beyond safety, it significantly boosts operational efficiency, slashes unexpected downtime, and optimizes maintenance costs over the long run.

Think about the financial implications of a sudden equipment breakdown. Production grinds to a halt, deadlines are missed, and you are left scrambling for emergency repairs, often at premium prices. A proper machine equipment inspection checklist template allows you to identify potential issues before they escalate into major problems. This shift from reactive crisis management to proactive prevention is a game-changer for your bottom line.

Moreover, regulatory compliance is a massive concern for many industries. Various safety standards and occupational health regulations mandate regular equipment inspections and maintenance records. A detailed checklist not only guides your inspection process but also serves as documented proof of your adherence to these crucial guidelines, protecting your organization from hefty fines and legal repercussions. It builds a culture of accountability and diligence.

What makes an inspection checklist truly effective is its comprehensive nature. It is not just a simple list of “yes” or “no” questions; it is a meticulously designed document that prompts thorough examination, encourages detailed notation, and provides a clear audit trail. The level of detail will vary depending on the equipment, but the core principle remains the same: leave no stone unturned in the pursuit of optimal performance and safety.

By integrating a structured checklist into your routine, you are essentially creating a standardized procedure that ensures consistency regardless of who is performing the inspection. This minimizes human error and guarantees that every critical point is covered every single time. It democratizes the inspection process, making it accessible and effective for all trained personnel.

Key Elements to Include in Your Checklist

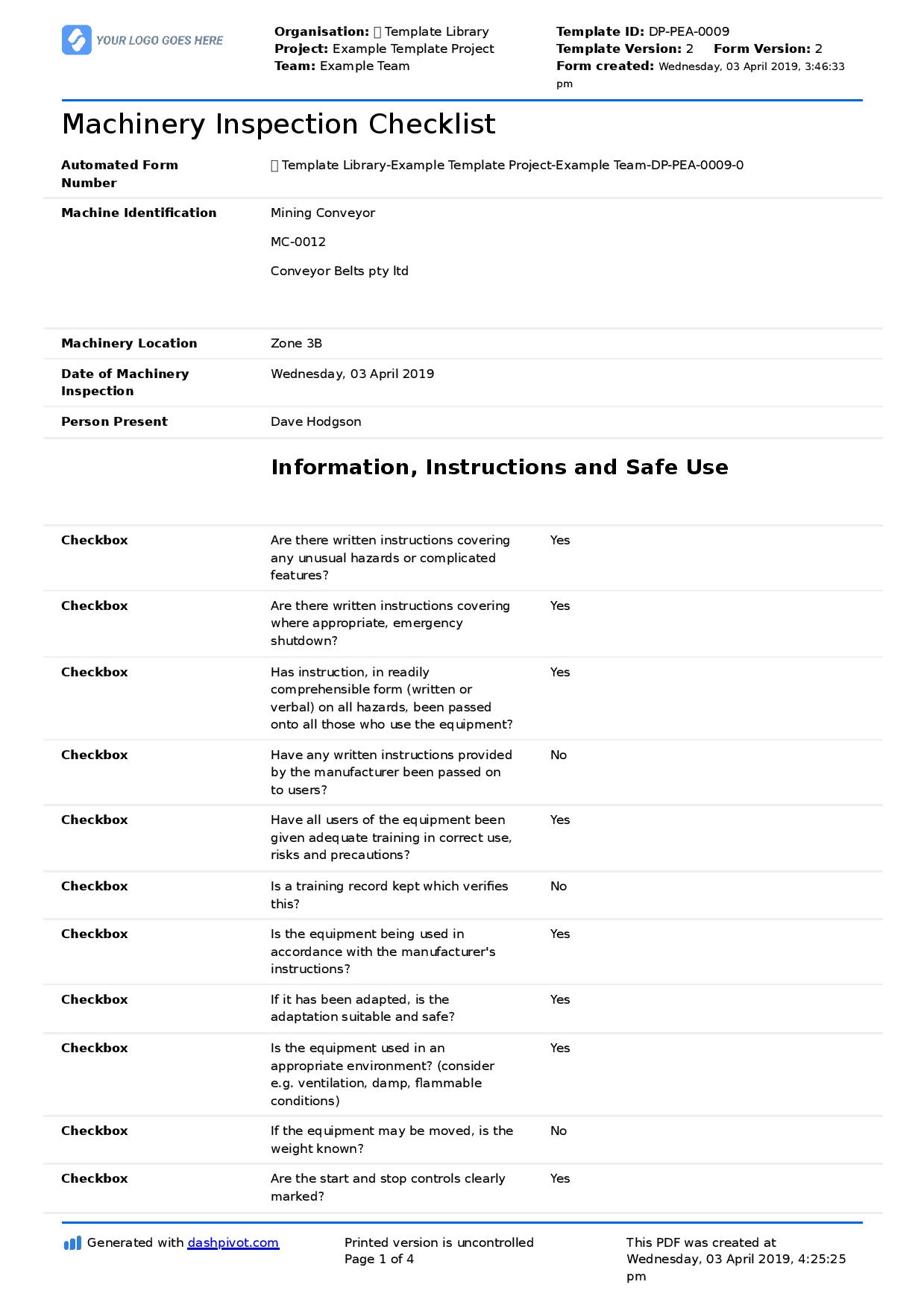

- Equipment Identification Details: Include fields for equipment ID, model number, location, and the date and time of inspection.

- Inspector Information: Record the name and signature of the person performing the inspection.

- Visual Checks: Look for obvious signs of damage, leaks, corrosion, loose fasteners, or excessive wear on external components.

- Operational Checks: Verify that all controls, gauges, lights, and safety mechanisms are functioning correctly.

- Fluid Levels: Inspect and top up engine oil, hydraulic fluid, coolant, and fuel as needed.

- Electrical Systems: Check wiring for fraying or damage, ensure connections are secure, and test emergency stops.

- Mechanical Components: Examine belts, chains, gears, and moving parts for proper tension, lubrication, and alignment.

- Safety Features: Confirm that guards are in place, emergency stops are operational, and warning labels are legible.

- Environmental Conditions: Note any potential hazards in the surrounding area that could affect equipment operation or safety.

- Action Required Section: Provide space for detailing any identified issues and the corrective actions taken or recommended.

Building Your Own Effective Machine Equipment Inspection Checklist Template

Creating a machine equipment inspection checklist template that truly serves your specific needs requires a thoughtful approach. While generic templates can be a starting point, the most effective checklists are those tailored to the unique machinery, operational environment, and regulatory requirements of your facility. It is not a one-size-fits-all solution; customization is key to its success.

The first step in building your bespoke template involves a thorough inventory of your equipment. For each piece of machinery, consult the manufacturer’s operational manual for recommended inspection points and frequencies. This technical documentation is invaluable, as it highlights critical components and specific maintenance protocols designed by the experts who built the machine.

Next, engage with the people who operate and maintain the equipment daily. Their practical experience provides unique insights into common failure points, operational quirks, and practical considerations that might not be covered in a manual. Combining manufacturer specifications with real-world feedback ensures your checklist is both technically sound and practically applicable.

Structuring your checklist logically is also vital for ease of use and completeness. Group related inspection items together, perhaps by system (e.g., electrical, hydraulic, mechanical) or by location on the machine. Use clear, concise language for each inspection item, avoiding jargon where possible, and provide simple ‘Pass/Fail’ or ‘OK/Not OK’ options, alongside space for detailed comments or corrective actions.

- Define the scope and frequency of each inspection, whether daily, weekly, or monthly.

- Categorize checks into logical sections for easy navigation.

- Use actionable language for each item; for example, “Check for leaks” instead of just “Leaks”.

- Include specific parameters where applicable, such as “Oil level within min/max range”.

- Provide clear instructions on what constitutes a ‘fail’ and the immediate actions required.

- Incorporate a section for recommended follow-up actions and deadlines.

- Consider digitalizing your checklist for easier data collection, analysis, and record-keeping.

Finally, remember that your machine equipment inspection checklist template should be a living document. As new equipment is introduced, operational procedures change, or new regulations emerge, your checklist needs to be updated accordingly. Regular reviews and revisions ensure its continued relevance and effectiveness in maintaining a safe and efficient workplace.

Implementing a well-designed machine equipment inspection checklist template is more than just a procedural formality; it is a foundational pillar of operational excellence. It systematically embeds safety, efficiency, and longevity into your daily routines, transforming reactive maintenance into proactive asset management. This meticulous approach minimizes costly surprises and ensures your machinery operates at its peak performance.

By embracing a comprehensive inspection strategy, you are not just ticking boxes; you are actively investing in the health of your equipment, the safety of your team, and the uninterrupted productivity of your operations. It empowers your team to identify and address minor issues before they escalate, fostering a culture of preventative care that safeguards your assets and secures your long-term success.