Maintaining a bustling kitchen, whether it’s in a restaurant, a school, or a healthcare facility, means relying heavily on your equipment. From the mighty oven to the humble mixer, every piece plays a crucial role in daily operations. When equipment fails unexpectedly, it doesn’t just halt productivity; it can lead to significant financial losses, spoiled ingredients, and frustrated staff and customers.

That’s where the power of proactive care comes in. Instead of waiting for a breakdown to occur, a systematic approach to maintenance ensures your kitchen runs smoothly, efficiently, and safely. Implementing a well-structured preventive maintenance plan is key to extending the lifespan of your valuable assets and avoiding costly emergency repairs. Having a clear guide, like a dedicated kitchen equipment preventive maintenance checklist template, simplifies this crucial task for everyone involved.

Why Proactive Maintenance is Your Kitchen’s Best Friend

Ignoring the regular upkeep of your kitchen equipment is like driving a car without ever changing the oil. Eventually, something is going to seize up, and it will often happen at the worst possible time. Unexpected breakdowns during peak service hours can throw an entire operation into disarray, leading to lost revenue, wasted food, and a frantic search for emergency repairs. Beyond the immediate chaos, poor maintenance can also compromise food safety standards, putting your business at risk of health code violations and a damaged reputation.

On the flip side, embracing preventive maintenance offers a wealth of benefits. It significantly extends the operational lifespan of your equipment, meaning you won’t have to invest in costly replacements as frequently. Properly maintained machines operate more efficiently, consuming less energy and reducing your utility bills. Moreover, a consistent maintenance schedule ensures equipment is always operating within safe parameters, protecting your staff from potential hazards and ensuring a smoother workflow.

Think of all the complex machinery working together in your kitchen: ovens, fryers, refrigerators, dishwashers, slicers, and more. Each has its own set of moving parts, heating elements, and intricate systems that require specific attention. A generic approach simply won’t cut it. You need a detailed, equipment-specific plan to address the unique needs of each machine, from routine cleaning to more complex inspections.

Key Elements of a Robust Checklist

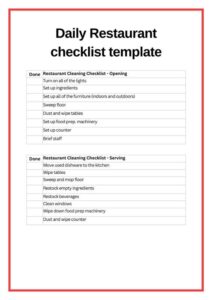

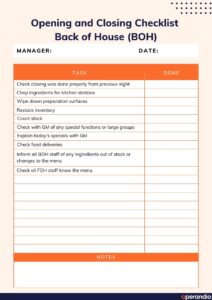

A truly effective kitchen equipment preventive maintenance checklist template isn’t just a list of items; it’s a living document that guides your team through essential tasks. It should outline a clear schedule for various checks, distinguishing between daily, weekly, monthly, and even quarterly or annual requirements. This tiered approach ensures that critical tasks are performed frequently, while less urgent but equally important ones are not overlooked.

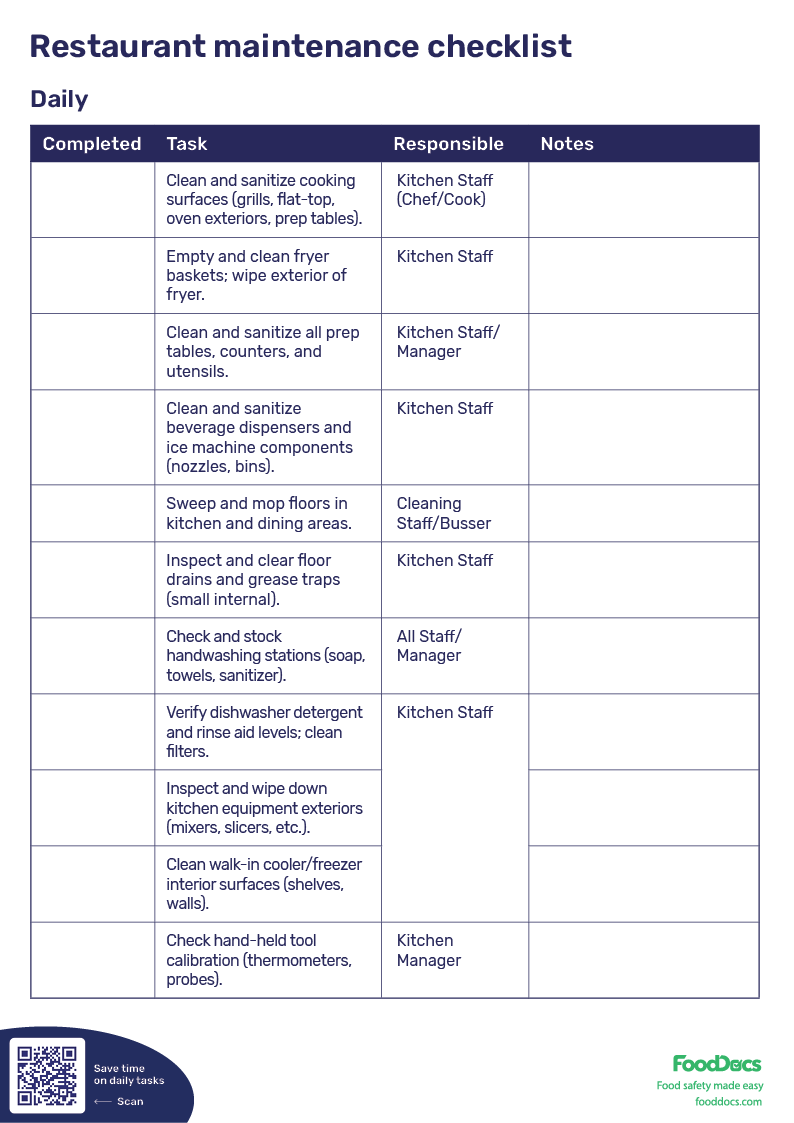

- Daily Tasks: These typically involve basic cleaning, sanitizing surfaces, checking temperatures (for refrigeration), and inspecting for obvious damage or leaks. These quick checks prevent minor issues from escalating.

- Weekly Tasks: Go a bit deeper, including thorough cleaning of filters, degreasing specific components, checking seals and gaskets for wear, and ensuring all safety features are operational.

- Monthly/Quarterly Tasks: These often involve more technical inspections, lubrication of moving parts, calibration of thermostats, checking electrical connections, and potentially scheduling professional service for more complex diagnostic checks.

Regular review and adaptation are also crucial. As your kitchen evolves, or as you acquire new equipment, your checklist should be updated to reflect these changes. Engaging your kitchen staff in this process ensures practicality and buy-in, making the maintenance routine a shared responsibility rather than a burden.

Building Your Own Tailored Maintenance Plan

Creating an effective kitchen equipment preventive maintenance checklist template doesn’t have to be overwhelming. The first step is to conduct a comprehensive inventory of all your kitchen equipment. List every single item, from your commercial convection oven down to your food processors. For each piece, gather its make, model, and any manufacturer-recommended maintenance guidelines, which are often found in the owner’s manual.

Once you have your inventory, categorize your equipment. Common categories include cooking equipment (ovens, ranges, fryers, griddles), refrigeration (reach-ins, walk-ins, freezers), dishwashing (dishwashers, pot washers), and preparation equipment (mixers, slicers, blenders). This categorization will help you streamline tasks, as similar types of equipment often require similar maintenance procedures.

Next, for each category and individual piece of equipment, detail the specific preventive maintenance tasks. Think about what needs to be done, how often, and who is responsible. Be as specific as possible to avoid ambiguity. For instance, instead of just “clean,” specify “clean oven interior with approved commercial cleaner, ensuring no residue remains.”

- Refrigeration: Clean condenser coils, check door gaskets for tears or proper seal, monitor and log internal temperatures, defrost freezers regularly.

- Ovens and Ranges: Clean burner grates and drip pans, calibrate thermostats, inspect ignition systems, check door hinges and seals for proper function.

- Fryers: Filter oil daily, boil out regularly, check thermostat accuracy, inspect heating elements.

- Dishwashers: Clean spray arms and filters, check detergent and rinse aid levels, descale internal components as needed, inspect for leaks.

- Mixers and Slicers: Lubricate moving parts, sharpen blades (slicers), inspect safety guards, ensure secure attachment of components.

Finally, implement a system for scheduling these tasks and, critically, for recording when they were performed. A simple logbook, a digital spreadsheet, or specialized maintenance software can all serve this purpose. Documentation is vital not only for tracking progress but also for demonstrating compliance during inspections and for identifying recurring issues that might indicate a need for professional service or equipment replacement.

Adopting a structured approach to kitchen equipment care isn’t just about fixing things when they break; it’s about fostering a culture of longevity and efficiency. When every piece of equipment is regularly checked, cleaned, and serviced, your kitchen operates as a well-oiled machine, capable of handling the demands of any service period.

This commitment to consistent, proactive maintenance translates directly into peace of mind for you and your team. You’ll experience fewer unexpected disruptions, lower operational costs, and a safer, more productive environment where your culinary creations can truly shine, day in and day out.