Every day, countless heavy vehicles hit the roads and job sites, essential for everything from construction to logistics. Before the engine roars to life and the wheels start turning, a crucial step ensures safety, compliance, and operational efficiency: a thorough pre-start inspection. Having a robust heavy vehicle pre start checklist template isn’t just a good idea; it’s a fundamental requirement for anyone operating or managing these powerful machines. It’s the first line of defense against preventable accidents and costly breakdowns.

Ignoring these vital checks can have severe consequences. Imagine a faulty brake light on a truck carrying a heavy load, or an underinflated tire on a bus full of passengers. Such oversights don’t just lead to inconvenience; they can result in serious injuries, fatalities, significant property damage, and severe legal repercussions. It’s a small investment of time at the start of a shift that pays dividends in safety and peace of mind throughout the entire workday.

This article will explore why a comprehensive checklist is indispensable, what elements it should ideally include, and how you can tailor it to meet your specific operational needs. By standardizing your pre-start procedures with a well-designed template, you empower drivers, enhance safety protocols, and contribute to a more reliable and efficient fleet operation.

Why a Robust Pre-Start Checklist is Non-Negotiable

The importance of a rigorous pre-start check for heavy vehicles extends far beyond merely ticking boxes. It’s a proactive safety measure that underpins the entire operational integrity of your fleet and the well-being of everyone involved. This initial inspection sets the tone for the entire shift, identifying potential issues before they escalate into dangerous situations or lead to costly downtime.

First and foremost, it’s about safety. Heavy vehicles are inherently powerful and, if not properly maintained and inspected, can pose significant risks. A detailed checklist ensures that critical safety components like brakes, lights, tires, and steering are all in proper working order. This minimizes the risk of accidents, protecting the driver, other road users, and pedestrians. Lives can literally depend on the thoroughness of these daily checks.

Beyond immediate safety, there’s the critical aspect of legal compliance. Most jurisdictions have stringent regulations regarding the roadworthiness of commercial vehicles. Failing to conduct and document pre-start inspections can lead to heavy fines, penalties, vehicle impoundment, and even criminal charges in the event of an incident. A properly completed heavy vehicle pre start checklist template serves as proof of due diligence, demonstrating that your organization is committed to adhering to industry standards and legal requirements.

Operational efficiency is another significant benefit. Catching a minor issue, such as a low fluid level or a frayed belt, during a pre-start check is far less disruptive and expensive than dealing with a breakdown halfway through a delivery or project. Preventative checks reduce unscheduled downtime, keep vehicles on schedule, and avoid the additional costs associated with emergency repairs, towing, and missed deadlines.

Furthermore, these checks contribute to the longevity and overall health of your fleet. Regular scrutiny allows for early detection of wear and tear, enabling proactive maintenance rather than reactive repairs. This extends the lifespan of components and the vehicle itself, ultimately reducing long-term operating costs and maximizing your investment.

Finally, pre-start checklists foster a culture of accountability and responsibility among drivers. When drivers are systematically required to inspect their vehicles, they become more attuned to their equipment and more invested in its safe operation. This empowerment leads to better vehicle care and a heightened sense of professional duty.

Key Components of an Effective Checklist

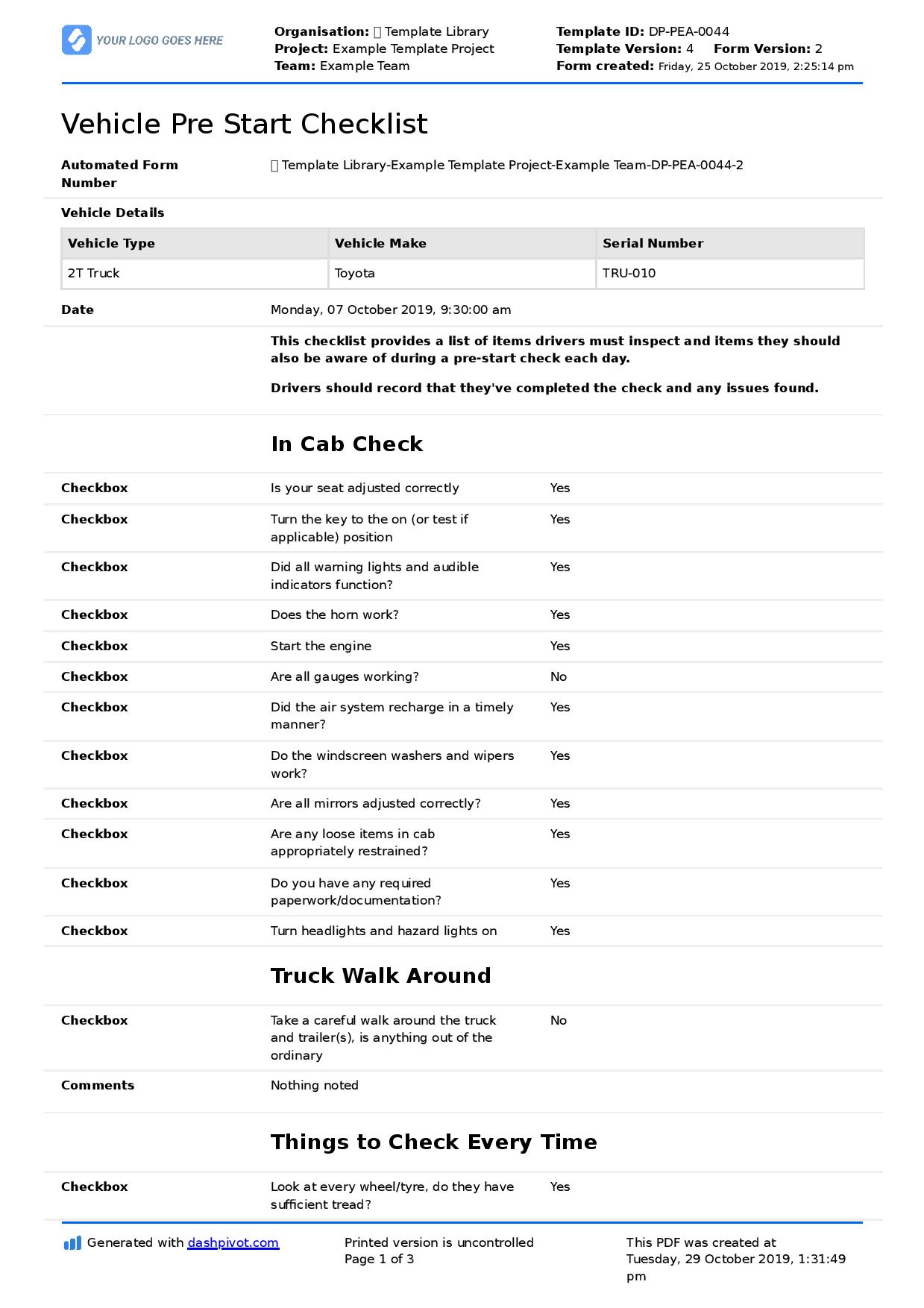

An ideal heavy vehicle pre-start checklist template should cover a broad range of inspection points. It typically starts with external checks, moving to under-the-hood components, then inside the cab, and finally any vehicle-specific or load-specific requirements.

External inspections usually include checking tire pressure and condition, ensuring all lights (headlights, tail lights, indicators, brake lights) are operational, inspecting mirrors for damage and proper adjustment, and verifying that wipers and horn are working. Security of cargo and trailers, including connections, also falls into this category.

Under the hood, checks involve fluid levels (engine oil, coolant, brake fluid, power steering fluid), inspecting belts and hoses for signs of wear or leaks, and checking the battery terminals. These are quick checks that can prevent serious mechanical failures.

Inside the cab, the driver should verify the functionality of all gauges and warning lights, test the steering and brakes (including air brake checks if applicable), ensure the seatbelt is in good condition, and confirm that all safety equipment (first-aid kit, fire extinguisher, warning triangles) is present and accessible.

Customizing Your Heavy Vehicle Pre Start Checklist Template

While a generic heavy vehicle pre start checklist template provides an excellent foundation, its true power lies in its adaptability. No two heavy vehicle operations are exactly alike; a flatbed truck transporting steel has different pre-start requirements than a refuse collection vehicle or a passenger bus. Therefore, customizing your template to reflect the specific types of vehicles in your fleet, the nature of your operations, and the environments in which they operate is crucial for maximum effectiveness.

Think about the unique characteristics of each vehicle. Does it have specialized equipment like a crane, a liftgate, a mixer, or refrigeration units? Each of these components needs its own dedicated inspection points within the pre-start routine. For example, a crane truck’s checklist would include checks for hydraulic levels, outrigger functionality, and boom condition, none of which would be relevant for a standard delivery van. The operating environment also plays a role. Vehicles regularly traversing rough terrain might need more frequent suspension and tire checks, while those operating in extremely cold climates would focus on anti-freeze levels and battery health.

Customization also involves integrating regulatory requirements specific to your industry or cargo. Transporting hazardous materials, for instance, comes with a host of additional pre-trip inspections that must be meticulously documented. By tailoring your heavy vehicle pre start checklist template, you not only improve safety but also ensure full compliance and reduce the risk of costly oversights.

Here are some elements to consider when customizing your template:

- Vehicle-specific components (e.g., boom, mixer, liftgate, specific braking systems).

- Cargo-specific security and safety checks (e.g., hazmat placards, refrigeration temperatures, tie-down integrity).

- Route or environment-specific considerations (e.g., mountain brakes for hilly routes, snow chains for winter conditions).

- Industry-specific regulatory requirements.

- Company-specific policies or procedures.

Implementing a detailed and customized pre-start checklist is more than just a regulatory formality; it’s a strategic investment in the safety, reliability, and longevity of your heavy vehicle fleet. By empowering drivers with a clear, systematic routine for inspection, you significantly reduce the potential for accidents, minimize costly downtime, and ensure your operations run smoothly day in and day out. It builds a robust foundation for a responsible and efficient transport or construction business.

Taking the time to develop and consistently apply a well-tailored checklist demonstrates a commitment to excellence and a proactive approach to risk management. It instills confidence in your drivers, your clients, and the public, reinforcing your reputation for safety and professionalism. Make this vital step a cornerstone of your daily operations, and watch as it contributes to a safer, more productive, and more sustainable future for your heavy vehicle fleet.