Running a fleet of heavy equipment means constantly juggling a lot of moving parts – literally. From excavators to bulldozers, each machine represents a significant investment and a critical component of your operations. The last thing any project manager or business owner wants is unexpected downtime, which can quickly spiral into missed deadlines, frustrated clients, and substantial repair costs. Proactive care is not just a good idea; it’s the backbone of operational efficiency and long-term profitability.

That’s where a well-structured maintenance routine comes into play. Think of it as your equipment’s regular health check-up, catching minor issues before they become major headaches. Implementing a systematic approach to equipment upkeep ensures longevity, boosts safety, and keeps your projects moving smoothly. A solid heavy equipment maintenance checklist template is your secret weapon in this endeavor, providing a clear, step-by-step guide to keeping every piece of machinery in peak condition.

Why a Robust Maintenance Checklist is Your Best Friend

In the demanding world of construction, mining, and agriculture, relying on reactive maintenance is a surefire way to run into trouble. Waiting for a component to fail before addressing it not only leads to expensive emergency repairs but also causes unpredictable operational halts. A robust maintenance checklist shifts your strategy from firefighting to prevention, allowing you to schedule inspections and services systematically, minimizing surprises and maximizing uptime. It’s about being prepared, not just responding.

Beyond simply avoiding breakdowns, a comprehensive checklist plays a crucial role in extending the overall lifespan of your valuable assets. Regular checks of fluids, filters, tires, and structural components help identify wear and tear early on, allowing for timely replacements or repairs. This proactive approach ensures that your equipment continues to perform at its best for years, protecting your investment and delaying the need for costly new acquisitions. It’s a smart financial move.

Safety is another non-negotiable aspect where a detailed maintenance checklist shines. Faulty equipment is a leading cause of workplace accidents and injuries. By rigorously inspecting safety features like brakes, lights, alarms, and emergency shut-offs, you drastically reduce the risk to your operators and ground crew. A well-maintained machine is a safer machine, fostering a secure work environment and potentially lowering insurance premiums.

Furthermore, a standardized checklist aids in better budget management. When you can anticipate maintenance needs and schedule them, you gain more control over your expenditures. Emergency repairs often come with premium prices for parts and labor, whereas planned maintenance allows for cost-effective procurement and optimized scheduling. This predictability helps in creating more accurate financial forecasts and avoids unexpected drains on your capital.

Finally, using a consistent heavy equipment maintenance checklist template helps maintain detailed records, which can be invaluable. These records provide a history of maintenance activities, part replacements, and any recurring issues. This data is not only useful for troubleshooting but also essential for demonstrating compliance with regulatory bodies and can significantly boost the resale value of your equipment. Potential buyers are often willing to pay more for machines with a proven track record of diligent maintenance.

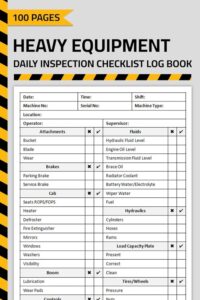

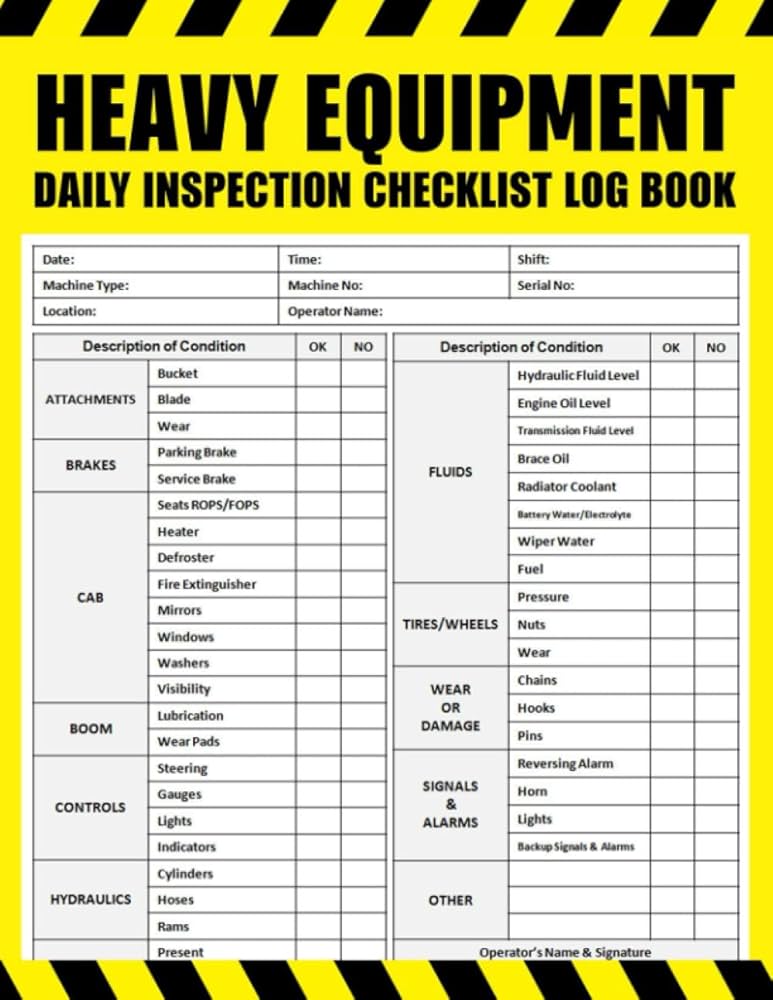

Key Inspection Areas for Your Checklist

- Fluid Levels and Condition (engine oil, hydraulic fluid, coolant, brake fluid)

- Filter Inspection and Replacement (air, oil, fuel, hydraulic)

- Tire and Track Condition (pressure, tread depth, wear, tension)

- Electrical Systems (lights, battery, wiring, dashboard indicators)

- Hydraulic Systems (hoses, cylinders, pumps, leaks)

- Brakes and Steering (functionality, fluid levels, wear)

- Safety Features (seatbelts, alarms, fire extinguishers, mirrors)

- Structural Integrity (welds, chassis, attachments, pins, bushings)

Building Your Own Heavy Equipment Maintenance Checklist Template

Creating an effective heavy equipment maintenance checklist template doesn’t have to be a daunting task. The best place to start is always with the manufacturer’s recommendations. Every piece of heavy equipment comes with an operator’s manual that outlines specific service intervals and inspection points. These guidelines are designed to ensure optimal performance and longevity, so they should form the foundation of your customized checklist. Don’t skip this crucial first step.

Once you have the manufacturer’s suggestions, it’s time to tailor the checklist to your specific operational environment and the unique challenges your equipment faces. For example, machinery operating in dusty conditions will require more frequent air filter checks than equipment used in cleaner environments. Similarly, excavators used for heavy digging might need more frequent hydraulic system inspections than those performing lighter tasks. Consider the actual workload and environmental factors when customizing.

An effective heavy equipment maintenance checklist template should include specific elements to ensure comprehensive record-keeping and accountability. Each item on the list should have a clear space for the date of inspection, the name or ID of the inspector, the equipment’s identification number, a clear description of the item being checked, the action taken (e.g., “OK,” “Adjusted,” “Repaired,” “Replaced”), and any relevant notes or observations. This detailed approach makes tracking issues and trends much easier.

Consider whether a physical paper checklist or a digital solution works best for your team. Digital checklists, often accessible via mobile apps, can offer benefits like automated reminders, photo attachments, and direct integration with inventory management systems for parts ordering. However, a simple, laminated paper checklist can also be highly effective in the field, especially in areas with poor connectivity. The key is to choose a system that your team will consistently use and understand.

Ultimately, your heavy equipment is the lifeblood of your operation, and keeping it in top shape is paramount. A well-designed maintenance checklist isn’t just a list of tasks; it’s a strategic tool that empowers your team to be proactive, identify potential issues early, and ensure every machine performs reliably. Investing time into developing and implementing a thorough maintenance routine will pay dividends in reduced downtime, enhanced safety, and greater financial stability for your business. Embrace the power of a systematic approach, and watch your equipment — and your projects — thrive.