Operating heavy equipment is central to many industries, from construction and mining to agriculture and logistics. These powerful machines represent a significant investment, often costing hundreds of thousands or even millions of dollars. Beyond the financial outlay, the safety of operators and surrounding personnel is paramount. Ensuring that this equipment is always in peak operating condition isn’t just good practice; it’s a fundamental requirement for productivity, efficiency, and safety on any job site.

That’s where a robust system for checks and maintenance comes into play. Without a structured approach, critical issues can easily be overlooked, leading to costly breakdowns, project delays, or, worst of all, serious accidents. Adopting a comprehensive heavy equipment inspection checklist template is the most effective way to standardize these crucial pre-operation and periodic checks, ensuring nothing is missed and your operations run smoothly and safely.

Why a Robust Heavy Equipment Inspection Checklist is Non-Negotiable

When you consider the daily demands placed on bulldozers, excavators, loaders, and cranes, it’s clear that wear and tear are inevitable. A well-designed inspection process, guided by a heavy equipment inspection checklist template, acts as your first line of defense against unexpected failures. It’s not just about ticking boxes; it’s about fostering a culture of proactive maintenance and safety awareness that permeates your entire operation.

Firstly, safety stands above all else. Malfunctioning equipment is a major cause of workplace accidents, leading to injuries, fatalities, and significant legal repercussions. A thorough inspection can identify faulty brakes, worn hydraulic lines, or non-functional safety alarms before they cause catastrophic failure. By catching these issues early, you protect your team and maintain a safe working environment.

Beyond safety, consistent inspections dramatically improve operational efficiency. Downtime due to unexpected equipment failure can halt an entire project, leading to missed deadlines and escalating costs. Preventative checks help you identify minor issues before they escalate into major, time-consuming, and expensive repairs. This keeps your machines running longer and performing better, directly impacting your project timelines and profitability.

Furthermore, a documented inspection history is invaluable for compliance and asset management. Many regulatory bodies require specific inspection protocols for heavy machinery. Having a clear, well-maintained checklist provides evidence of your adherence to these standards, protecting you from fines and liabilities. It also helps in tracking the health of your assets over time, informing maintenance schedules, and making informed decisions about repair versus replacement.

Ultimately, consistent use of a detailed inspection template extends the lifespan of your valuable machinery. Regular checks allow for timely lubrication, component replacement, and minor adjustments that prevent accelerated wear and tear. This protects your substantial investment and helps retain the equipment’s value, which is crucial for resale or trade-in purposes.

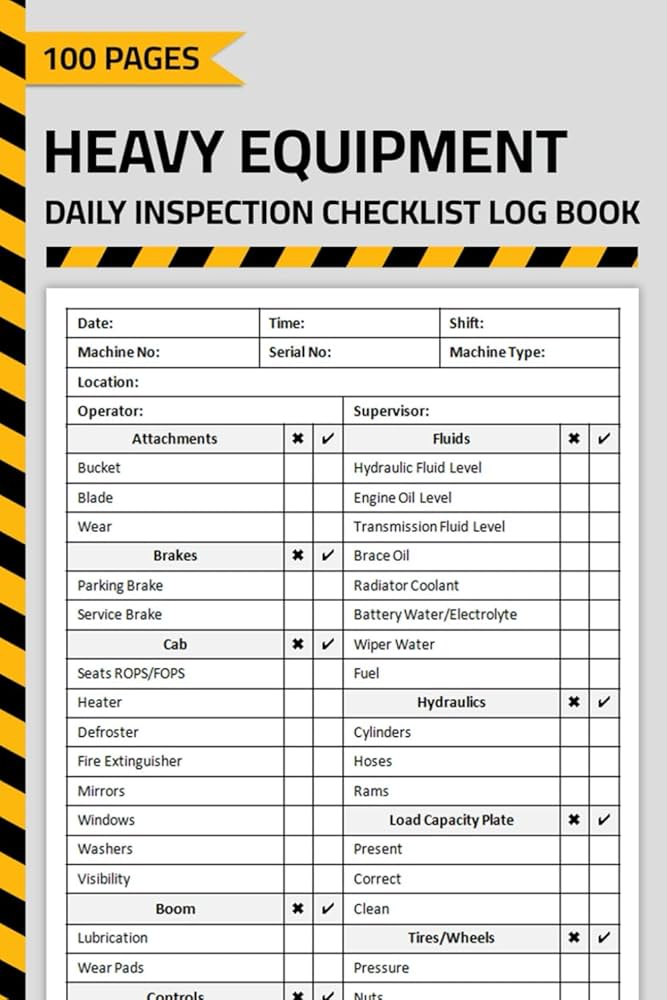

Key Areas to Include in Your Inspection

- Engine and Fluid Levels: Checking oil, coolant, hydraulic fluid, and fuel levels, along with identifying any leaks.

- Tires and Undercarriage: Inspecting tire pressure, tread depth, lug nuts, tracks, rollers, and sprockets for wear or damage.

- Hydraulics and Hoses: Looking for leaks, cracks, or damage to hydraulic cylinders, lines, and fittings.

- Electrical Systems and Lights: Ensuring all lights (headlights, brake lights, warning lights), gauges, and alarms are functioning correctly.

- Safety Features: Verifying the operation of brakes, seatbelts, horns, backup alarms, and fire extinguishers.

- Operator Cabin and Controls: Checking the functionality of steering, pedals, joysticks, and ensuring the cabin is clean and free of obstructions.

Building Your Ideal Heavy Equipment Inspection Checklist Template

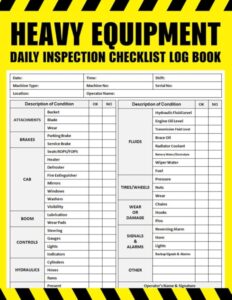

Creating an effective heavy equipment inspection checklist template isn’t a one-size-fits-all endeavor. The ideal template will be tailored to the specific types of equipment you operate, the environmental conditions they work in, and the specific regulatory requirements of your industry. While there are many general templates available, customizing one to your unique needs will yield the best results for safety and efficiency.

Start by identifying all the critical components for each piece of equipment. Consider manufacturer recommendations for daily, weekly, and monthly checks. Involve experienced operators and mechanics in the development process, as their practical insights are invaluable for identifying common failure points and essential inspection items. A good template should be easy to understand and quick to complete, encouraging consistent use.

When structuring your template, think about clear sections for different areas of the machine, as well as fields for administrative details. This makes the inspection process logical and ensures all necessary information is captured. Consider incorporating a rating system (e.g., “OK,” “Minor Issue,” “Major Issue”) for each item, allowing inspectors to quickly communicate the severity of any findings.

Finally, think about how the completed checklists will be managed. While paper checklists are a traditional approach, modern digital solutions offer significant advantages. Digital checklists can be completed on tablets or smartphones, allowing for easy data capture, photo attachments for documentation, and immediate reporting of issues. This streamlines the follow-up process, ensures accountability, and provides a clear audit trail for every piece of equipment.

- Equipment Identification Details: Make sure to include spaces for the equipment ID, make, model, and hour meter reading.

- Inspection Date and Inspector Name: Essential for tracking and accountability.

- Comprehensive List of Inspection Points: Organized logically by equipment section.

- Condition Rating System: A simple way to classify findings (e.g., Green/Yellow/Red, OK/Needs Attention/Critical).

- Action Required and Follow-up Sections: Space to note what actions need to be taken and when.

- Sign-off and Verification: A signature line for the inspector and a supervisor if required.

Adopting and consistently using a well-designed inspection template is a proactive step that will transform your equipment management strategy. It moves you from reactive repairs to preventative maintenance, significantly reducing operational risks and unexpected costs. By embedding these rigorous checks into your daily routine, you empower your team with the tools to maintain a safer, more productive, and ultimately more successful operation.

Embrace the power of a structured approach to heavy equipment checks. It’s an investment in your team’s safety, your equipment’s longevity, and your company’s bottom line. With a customized and consistently applied inspection regimen, you gain peace of mind, knowing that your valuable assets are being cared for, and your operations are running at peak performance, day in and day out.