Working at heights comes with inherent risks, and ensuring the safety of personnel is paramount. Unfortunately, fall-related incidents remain a leading cause of serious injuries and fatalities in many industries. This isn’t just about adhering to regulations; it’s about fostering a culture where every individual returns home safely at the end of the day. A crucial component of this safety strategy involves the meticulous and regular inspection of all fall protection equipment.

Without a systematic approach, vital checks can be missed, leading to potentially catastrophic failures. This is where a well-designed `fall protection inspection checklist template` becomes an indispensable tool, transforming a haphazard process into a thorough and standardized safety routine. It serves as your guide, ensuring that every piece of equipment, from harnesses to anchor points, meets the required safety standards before anyone puts their trust in it.

Why Regular Fall Protection Inspections Are Non-Negotiable

The “why” behind diligent fall protection inspections extends far beyond mere compliance. It’s fundamentally about human life. Each year, countless workers face the risk of severe injury or death due to falls from elevation. These incidents don’t just impact the individual and their family; they also carry significant financial burdens for companies, including medical costs, lost productivity, increased insurance premiums, and potential legal fees. A single overlooked defect in a harness or a worn-out lanyard could be the difference between a safe workday and a tragic accident.

Think about the sheer variety of equipment involved: full-body harnesses, energy-absorbing lanyards, self-retracting lifelines, anchor points, vertical and horizontal lifelines, and various connectors. Each of these components has specific wear patterns, operational requirements, and expiration dates. A generic visual check simply isn’t enough to identify the subtle signs of damage or degradation that could compromise its integrity. A structured inspection system is essential to catch these issues before they become critical failures.

The Dangers of Neglecting Inspections

Neglecting regular inspections opens the door to a multitude of hazards. Equipment might be used beyond its service life, exposing workers to components that have degraded over time due to UV exposure, chemical contamination, or simple wear and tear. Improper storage can lead to damage that is not immediately apparent, such as crushing or fraying. Furthermore, equipment that has been involved in a fall event must always be removed from service immediately, yet without proper inspection protocols, this crucial step could be overlooked.

Common oversights during informal inspections often include:

Such omissions are not minor; they are direct invitations to disaster. A comprehensive `fall protection inspection checklist template` helps standardize the process, ensuring that even inspectors with varying levels of experience are guided through every critical step. It acts as a memory aid and a confirmation tool, making sure nothing slips through the cracks. This systematic approach contributes significantly to maintaining the equipment’s reliability and extending its safe service life.

Building Your Effective Fall Protection Inspection Checklist Template

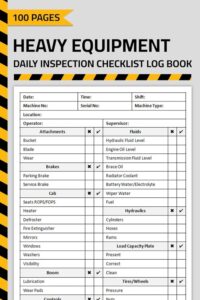

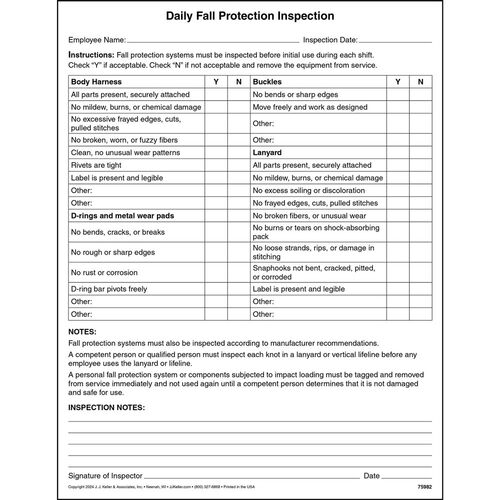

Creating a robust `fall protection inspection checklist template` involves more than just listing a few items. It needs to be a comprehensive document that guides the inspector through every necessary check for each type of fall protection equipment in use. Start by identifying all the specific pieces of equipment you have and then break down each item into its individual components for a detailed examination.

A good template should begin with basic administrative details, such as the date of inspection, the inspector’s name, the equipment’s unique identification number, and its manufacturer and model. This ensures accurate record-keeping and traceability. Following these details, the core of the checklist will meticulously outline specific points of inspection for each component.

For a full-body harness, for instance, your checklist should include:

Similarly, for lanyards and lifelines, the template should prompt checks for cuts, abrasions, fraying, and chemical damage on webbing or rope, and ensure that all connectors (like snap hooks and carabiners) function correctly, with no signs of deformation or corrosion. For self-retracting lifelines, pay close attention to the housing for damage, the lifeline for full retraction and locking mechanisms, and the impact indicator if present. Anchor points require visual inspection for structural integrity, signs of excessive wear, corrosion, and proper installation according to manufacturer specifications and regulatory standards.

Beyond the physical inspection, the template should also include sections for documenting the inspection outcome (pass/fail), any corrective actions required, and a signature line. This systematic documentation is vital for demonstrating compliance during audits and for tracking equipment history. Remember, your template should be a living document, adaptable to new equipment or changes in safety regulations. Regularly review and update it to ensure it remains relevant and effective for your specific work environment and the varied demands placed on your fall protection gear.

Implementing a rigorous inspection regimen through a well-designed `fall protection inspection checklist template` is not merely a procedural step; it’s an investment in your team’s safety and well-being. By standardizing these essential checks, you create a robust barrier against workplace accidents, fostering an environment where safety is always prioritized. This proactive approach not only prevents injuries but also builds confidence among workers, knowing that their equipment has been thoroughly vetted.

Ensuring every piece of gear is in optimal condition before it is relied upon for life support creates a foundation of trust and responsibility. It cultivates a safety-conscious culture that benefits everyone, from the individual worker on the scaffold to the management overseeing the project. Ultimately, consistent and detailed inspections are the cornerstone of an effective fall protection program, safeguarding lives and promoting a secure working atmosphere for all.