When you are about to invest in new equipment or a complex system, the moment it leaves the manufacturer’s facility is a critical juncture. This is where the Factory Acceptance Test, or FAT, comes into play. It is your crucial opportunity to verify that everything functions as expected, meets your specifications, and is ready for its journey to your site. Think of it as the ultimate quality control check before the product gets shipped.

However, simply showing up at the factory isn’t enough. To truly make the most of this vital inspection, you need a structured approach. Without a clear plan, it is easy to miss important details, overlook critical tests, or find yourself scrambling to document findings. This is precisely why a well-designed factory acceptance test checklist template becomes an indispensable tool in your project management arsenal.

Why a Robust Factory Acceptance Test Checklist is Your Best Friend

Imagine embarking on a complex journey without a map, or building an intricate structure without blueprints. The outcome would likely be chaos, delays, and unexpected costs. The same principle applies to conducting a Factory Acceptance Test. This isn’t just about ticking boxes; it’s about systematically verifying every component, every function, and every safety feature of your new asset before it ever reaches your premises. A comprehensive checklist acts as your roadmap, ensuring that no stone is left unturned and no critical step is overlooked.

The value of a detailed factory acceptance test checklist template extends far beyond mere organization. It serves as a consistent framework that guarantees all necessary tests are performed according to predefined standards and specifications. This proactive approach significantly mitigates the risk of discovering costly issues or functional discrepancies once the equipment is delivered and installed at your location. Finding problems at the factory is always less expensive and easier to resolve than finding them during on-site commissioning.

Furthermore, a standardized checklist fosters clear communication between your team and the manufacturer. Both parties know exactly what needs to be tested, what the expected outcomes are, and how performance will be measured. This transparency helps to prevent misunderstandings and disputes, creating a smoother, more collaborative testing environment. It also provides an objective record of the equipment’s condition and performance at the point of shipment.

Key Areas Your Checklist Should Cover

A truly effective checklist for a Factory Acceptance Test should be comprehensive, touching upon all critical aspects of the equipment or system. While specific details will vary depending on the asset, certain categories are universally applicable and form the backbone of a solid template.

- Documentation Review: Verify all manuals, drawings, datasheets, and certification documents are present and correct.

- Visual Inspection: Check for physical damage, proper labeling, correct components, and quality of workmanship.

- Functional Testing: Ensure all individual functions and sub-systems operate as designed according to specifications.

- Performance Verification: Measure key operational parameters like speed, throughput, accuracy, and energy consumption against agreed-upon benchmarks.

- Safety Checks: Confirm all safety interlocks, emergency stops, guards, and warning labels are in place and functioning.

- Software and Control System Checks: Validate software versions, parameter settings, alarm functionalities, and user interface responsiveness.

By systematically addressing each of these areas, your team can gain confidence that the equipment not only looks good but also performs exactly as intended. This structured approach ensures a thorough evaluation, leaving little room for error or oversight. It means you are not just testing the equipment, but also verifying the manufacturer’s adherence to all contractual obligations.

The beauty of a well-crafted checklist is its adaptability. While it provides a structured framework, it can and should be tailored to the unique requirements of each specific project. This flexibility ensures that while the core principles of verification remain constant, the finer points can be adjusted to match the complexity and specific demands of the equipment being tested, making it an invaluable, living document throughout the FAT process.

Crafting and Customizing Your Factory Acceptance Test Checklist

While having a general factory acceptance test checklist template is an excellent starting point, the real power comes from customizing it to your specific project needs. Every piece of equipment, every system, and every application has its own unique set of requirements and specifications. A generic checklist might cover the basics, but it won’t necessarily delve into the intricate details that are critical for your particular operation. Tailoring your checklist ensures that you are testing for the parameters that truly matter to you.

The process of customization often begins by thoroughly reviewing the purchase order, technical specifications, and any contractual agreements with the supplier. These documents are the ultimate source of truth regarding what the equipment is supposed to do and how it should perform. Your checklist should directly reference these specifications, translating them into measurable and verifiable test items. This ensures that every test conducted during the FAT is directly relevant to your agreed-upon criteria.

Involving a multidisciplinary team in the customization process can also yield significant benefits. Engineers, operators, maintenance personnel, and project managers each bring a unique perspective to the table. An engineer might focus on technical performance, while an operator could highlight user interface aspects, and maintenance staff might emphasize accessibility for servicing. This collaborative approach helps create a truly comprehensive and practical checklist.

- Understand Project Specifics: Delve into the unique requirements, environmental conditions, and operational goals for the new equipment.

- Review Supplier Documentation: Cross-reference the checklist items with drawings, P&IDs, control narratives, and test procedures provided by the manufacturer.

- Define Test Criteria: Clearly articulate what constitutes a pass or fail for each test, including acceptable tolerances and measurement methods.

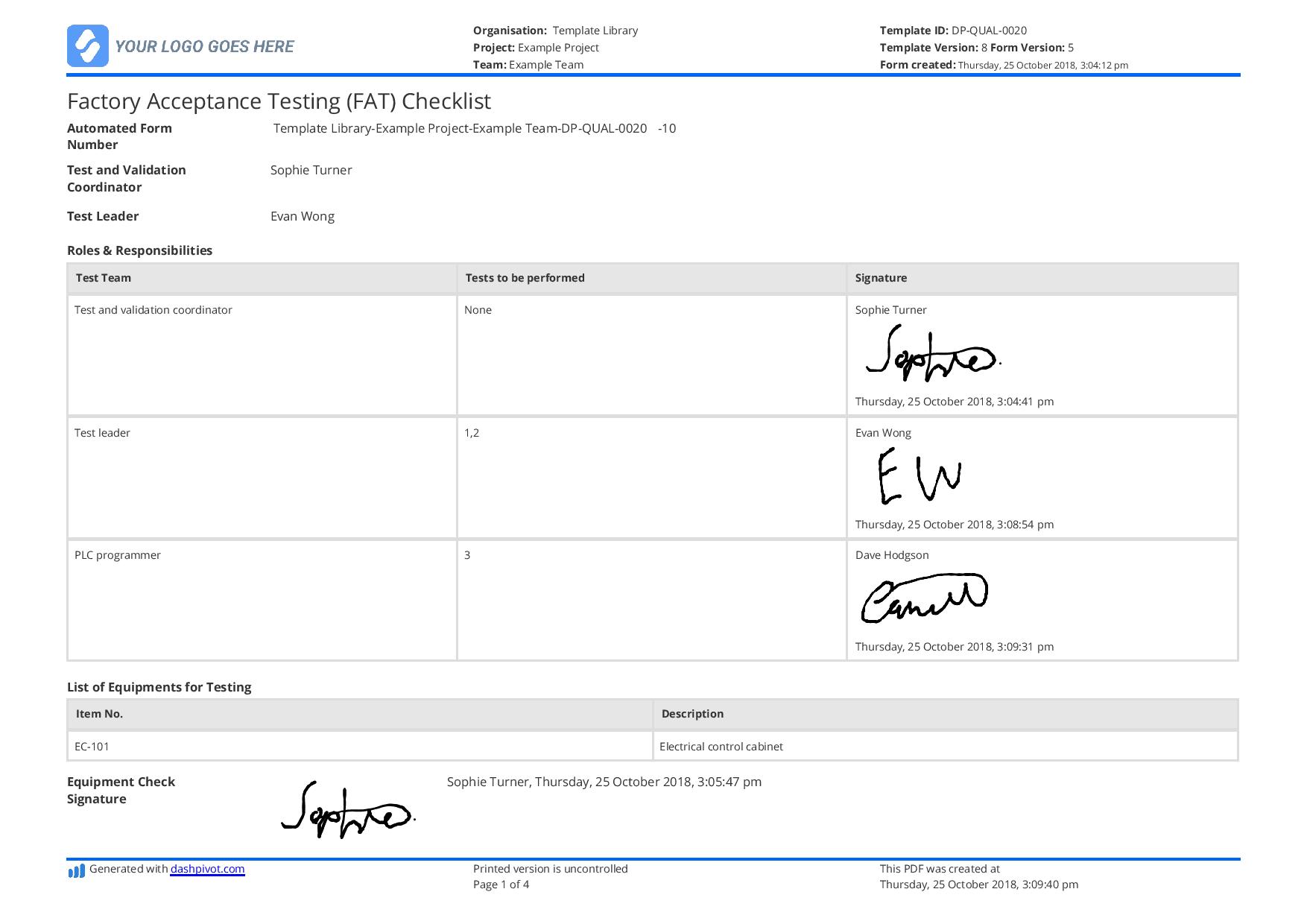

- Assign Responsibilities: Identify who is responsible for performing each test and who will verify the results, fostering accountability.

- Document Results Thoroughly: Create a clear system for recording test outcomes, observations, and any deviations found.

Beyond merely listing items, a good customized checklist should also include clear instructions for each test, specifying the method, instrumentation required, and the expected range of results. This level of detail removes ambiguity and ensures consistency, regardless of who is performing the test. Remember, the goal is to make the FAT as objective and reproducible as possible, setting a clear standard for acceptance.

Ultimately, your customized checklist becomes an integral part of the quality assurance process, not just for the equipment itself but for the entire project lifecycle. It provides a formal record of validation, a baseline for future operational performance, and a critical tool for continuous improvement, making your investment more secure from the very beginning.

Taking the time to meticulously plan and execute your Factory Acceptance Test with a well-defined checklist is not just a best practice; it is a fundamental pillar of successful project delivery. It represents your final opportunity to address potential issues efficiently and cost-effectively, safeguarding your investment and minimizing future headaches.

By embracing a structured approach, you ensure that the equipment arriving at your facility is not only physically sound but also fully compliant with your operational needs. This proactive verification process provides invaluable peace of mind, allowing you to move forward with installation and commissioning with confidence, knowing you have thoroughly vetted your new asset.