In the bustling world of industrial operations, keeping a plant running smoothly and safely is a top priority. Imagine the chaos and financial setbacks that can arise from unexpected equipment failure or, even worse, a safety incident. That’s why being proactive, rather than reactive, is not just a good idea; it’s absolutely essential for any successful enterprise.

This proactive approach often begins with diligent, routine checks. Ensuring every component is functioning as it should be, identifying potential issues before they escalate, and maintaining a secure environment are all critical tasks. A well-structured system for these daily observations can make all the difference, and that’s where a clear and comprehensive daily plant inspection checklist template becomes an invaluable tool for your team.

Why a Daily Plant Inspection Checklist is Your Operation’s Best Friend

Adopting a regular inspection routine is far more than just ticking boxes; it is the backbone of preventative maintenance and operational longevity. Daily inspections allow your team to catch minor wear and tear, fluid leaks, unusual noises, or slight deviations in performance before they develop into major, costly breakdowns. This foresight significantly extends the lifespan of your valuable machinery and reduces the likelihood of expensive emergency repairs or replacements.

Beyond asset protection, daily inspections are fundamentally about safety. A meticulously maintained plant is a safer plant. By regularly checking safety guards, emergency stop buttons, clear pathways, and the integrity of electrical systems, you are actively mitigating risks for your workforce. This commitment to safety not only protects lives but also helps your operation meet stringent regulatory standards, avoiding potential fines and ensuring compliance with industry best practices.

Consider the cumulative effect: fewer unexpected downtimes mean consistent production schedules and improved overall efficiency. When equipment is operating at its peak, energy consumption can be optimized, and resource waste minimized. This contributes directly to your bottom line, transforming what might seem like a simple daily task into a strategic operational advantage.

Key Areas to Cover in Your Daily Plant Walkthrough

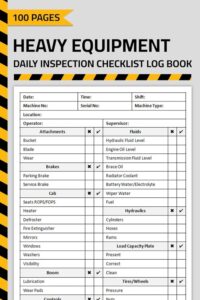

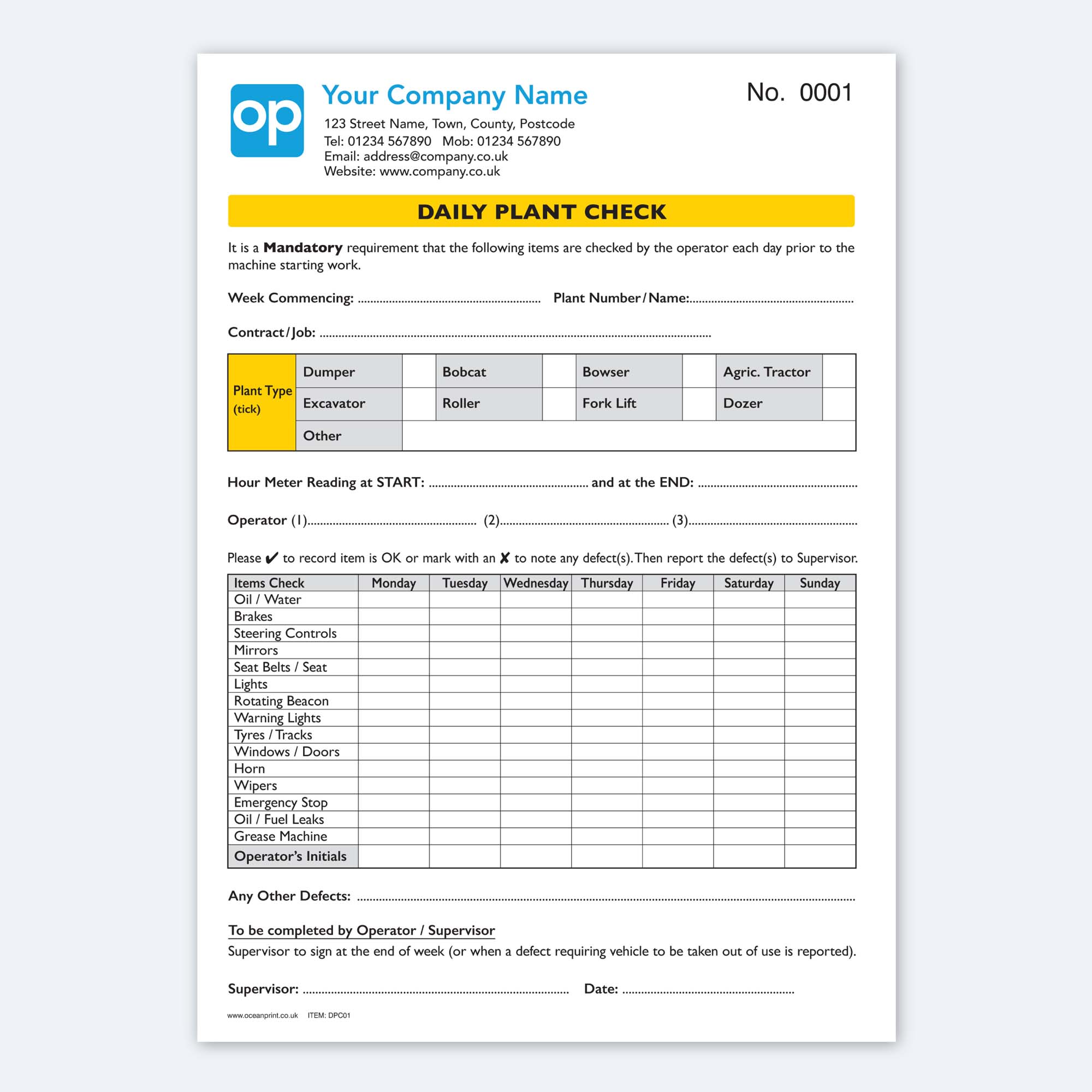

To ensure thoroughness, a daily plant inspection checklist template should guide inspectors through all critical areas. Here are some examples of what to include:

- Operational Equipment: Check motors, pumps, conveyors, and processing units for unusual vibrations, sounds, or visible damage. Ensure all moving parts are properly lubricated and guards are in place.

- Safety Infrastructure: Verify the functionality of emergency stop buttons, fire suppression systems, and alarms. Confirm that all safety signage is clear and unobstructed.

- Fluid Levels and Leaks: Inspect hydraulic fluid, coolant, and oil levels. Look for any signs of leaks around machinery, pipes, or storage tanks, which could indicate a failing seal or pipe.

- Electrical Systems: Examine power cables for fraying or exposure, ensure connections are secure, and check control panels for any abnormal indicators.

- Structural Integrity: Conduct a visual inspection of foundations, supports, and walkways for cracks, corrosion, or other structural concerns.

- Housekeeping and Environment: Ensure work areas are free of clutter, spills, and obstructions. Proper housekeeping prevents slips, trips, and falls, and helps maintain a clean operational environment.

A well-executed daily plant inspection goes a long way in cultivating a culture of vigilance and responsibility among your staff. It empowers them to take ownership of their work environment and contributes significantly to the overall success and resilience of your operations.

Building Your Tailored Daily Plant Inspection Checklist Template

While a general framework is helpful, the most effective inspection checklists are those specifically tailored to your unique plant and its equipment. Every facility has its own quirks, specialized machinery, and particular operational demands. Begin by reviewing existing equipment manuals, safety guidelines, and historical maintenance records to identify high-risk areas or components that require frequent attention.

Involving experienced personnel, such as maintenance technicians, operators, and safety officers, in the checklist creation process is crucial. They possess invaluable firsthand knowledge of the equipment’s typical behavior, common failure points, and critical safety considerations. Their input ensures that your daily plant inspection checklist template is not only comprehensive but also practical and easy for frontline staff to use consistently.

Think about the format that best suits your team. While traditional paper checklists are still common, many operations are now adopting digital solutions. Mobile apps or tablet-based forms can simplify data entry, allow for photo attachments of issues, and even automate the reporting process, providing real-time insights into your plant’s condition. The key is to choose a system that encourages compliance and simplifies the inspector’s job, rather than adding to it.

Once your daily plant inspection checklist is in place, it’s not a set-it-and-forget-it document. Regular training for all personnel involved in inspections is paramount, ensuring everyone understands what to look for, how to properly document findings, and the immediate steps to take if an issue is discovered. Furthermore, periodically review and update your checklist based on new equipment, process changes, or lessons learned from incidents. This iterative process ensures your inspection program remains robust and effective over time, adapting to the evolving needs of your operation.

Implementing a rigorous daily inspection routine is a strategic investment that yields substantial returns. It fosters a safer work environment, significantly enhances operational efficiency, and dramatically extends the lifespan of your valuable assets. By embedding this proactive approach into your daily operations, you’re not just preventing problems; you’re actively building a more resilient and productive future for your entire plant.

Embracing a structured system for these checks ensures that no critical detail is overlooked, transforming potential vulnerabilities into strengths. This diligent practice empowers your team, safeguards your resources, and ultimately drives continuous improvement across all facets of your industrial enterprise, securing peace of mind and operational excellence for years to come.