Imagine a crucial piece of machinery grinds to a halt in the middle of a busy production day. Every minute of downtime costs your business significant money, not just in lost output but also in potential customer dissatisfaction and missed deadlines. The frantic search for a replacement part begins, only for someone to realize it’s not in stock, or worse, nobody knows where to source it quickly. This scenario is a nightmare for any operations manager, and it’s precisely why proactive planning for equipment readiness is so vital.

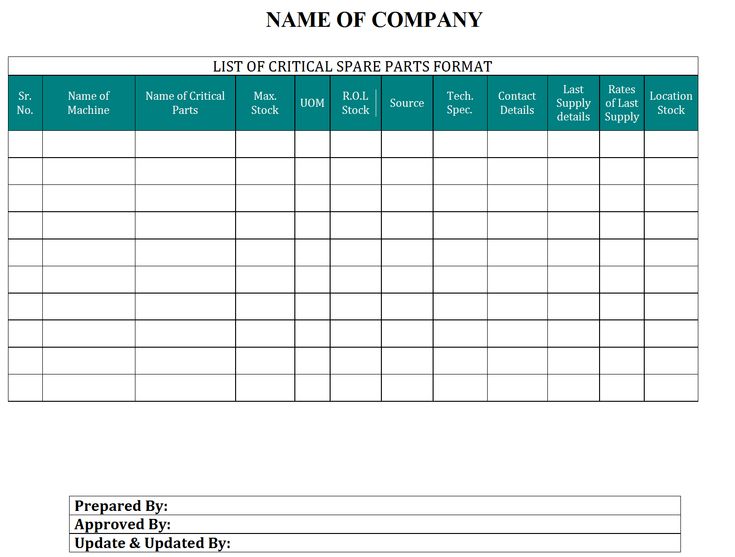

Preventing such costly interruptions is where a well-structured critical spare parts list template becomes an invaluable asset. This isn’t just a simple inventory sheet; it’s a strategic document designed to identify, prioritize, and manage the components that are absolutely essential for your operations to continue running smoothly. Having this list readily available means you can drastically cut down on repair times and minimize the financial impact of unexpected breakdowns.

By systematically documenting your most critical components, you transform reactive maintenance into a streamlined, efficient process. It empowers your team to make informed decisions, ensuring the right parts are on hand when they are needed most, rather than leaving everything to chance and risking extended operational outages. It’s about building resilience into your entire operational framework.

Why a Critical Spare Parts List Template is Your Operational Lifeline

The true cost of equipment downtime extends far beyond the immediate repair bill. It encompasses lost revenue, wasted labor, missed production targets, damage to reputation, and even potential safety hazards. Without a comprehensive strategy for managing spare parts, businesses are constantly exposed to these risks, operating under a cloud of uncertainty. A dedicated critical spare parts list template serves as a foundational tool to mitigate these very real threats, providing clarity and control over your inventory and maintenance planning. It ensures that when an unforeseen failure occurs, you’re not starting from scratch but rather executing a predefined recovery plan.

Identifying what truly constitutes a "critical" part involves more than just looking at its cost. It’s about evaluating its impact on overall operations. A low-cost fuse might be just as critical as an expensive motor if its failure can bring an entire production line to a standstill. Factors like lead time for procurement, availability from suppliers, and the presence of alternative solutions all play a role in determining criticality. This template helps you systematically assess each component through this lens, moving beyond simple assumptions to data-driven decisions.

A robust template will guide you through the process of capturing all necessary information for each part. It provides a consistent framework, ensuring no vital detail is overlooked, from the exact part number to the preferred supplier and historical usage data. This level of detail is crucial for efficient inventory management and ensures that your purchasing department can act swiftly and accurately when reordering is required.

Key Elements to Include in Your Template:

- **Part Name and Description:** Clear identification of the component.

- **Manufacturer and Part Number:** Essential for accurate ordering.

- **Supplier Information:** Primary and secondary suppliers, contact details.

- **Minimum/Maximum Stock Levels:** Based on usage, lead time, and criticality.

- **Lead Time:** How long it takes to receive the part once ordered.

- **Quantity on Hand:** Current inventory count.

- **Storage Location:** Where the part is physically stored in your facility.

- **Cost per Unit:** For budgeting and cost analysis.

- **Criticality Rating:** A scale (e.g., 1-5) indicating its impact on operations.

- **Associated Equipment:** Which machines or systems use this part.

Beyond merely listing items, the template prompts you to think strategically about each part’s lifecycle and potential failure points. It encourages regular review and updating, making sure your inventory remains aligned with your current equipment, production schedules, and supplier relationships. This dynamic approach prevents obsolescence and ensures your critical spares strategy evolves with your operational needs.

Implementing Your Critical Spare Parts Strategy Effectively

Creating a critical spare parts list template is a fantastic first step, but its true value is unlocked through effective implementation and ongoing management. It’s not a static document you create once and forget about; rather, it’s a living tool that requires continuous attention and integration into your daily operations. A well-implemented strategy ensures that the insights gained from your template translate directly into tangible benefits, minimizing downtime and optimizing your maintenance budget. This means embedding the use of the list into your maintenance workflows, training personnel, and establishing clear procedures for its upkeep.

Successful implementation often hinges on strong cross-functional collaboration. Your maintenance team identifies the parts and their criticality, but procurement needs to understand lead times and supplier relationships, while finance needs to approve budgets for stockholding. Operations management provides insights into production schedules and the impact of downtime. When all these departments work together, leveraging the critical spare parts list as a shared resource, you create a cohesive and resilient operational environment that can quickly adapt to challenges.

Furthermore, the data within your template should drive your inventory decisions. Regular audits of your physical inventory against the template’s records are essential to maintain accuracy. Establishing clear reorder points and processes ensures that critical stock levels are never breached. Training your team on how to use and update the template, along with understanding the impact of each critical part, transforms your spare parts strategy from a document into a core operational discipline that safeguards your productivity and profitability.

Investing in a robust plan for managing your essential components is a fundamental step towards operational excellence. It transforms potential chaos into predictable management, significantly reducing the stress and financial drain of unexpected equipment failures. By systematically identifying, prioritizing, and stocking the right parts, you empower your team to maintain efficiency and reliability, even when unforeseen challenges arise.

Embrace the discipline of proactive spare parts management. By leveraging a comprehensive approach, you’re not just stocking parts; you’re investing in the continuity and long-term success of your operations, ensuring that your machinery keeps running and your business stays productive, no matter what surprises the future holds.