In the intricate world of construction, where projects unfold across myriad stages and involve countless moving parts, maintaining a consistent standard of quality isn’t just a goal—it’s an absolute necessity. From the initial groundbreaking to the final coat of paint, every detail contributes to the overall success, safety, and longevity of a structure. Without a robust system in place, the chances of costly errors, reworks, and schedule delays significantly increase, not to mention the potential impact on reputation and client satisfaction.

This is precisely where a well-designed construction quality control checklist template becomes an indispensable tool. It acts as your project’s guardian, ensuring that nothing is overlooked and that all work adheres to the highest possible standards and regulatory requirements. Imagine having a clear, actionable guide that simplifies complex processes, empowers your team, and ultimately delivers a superior finished product. That’s the power we’re talking about, and it’s within reach for every construction endeavor.

Elevating Project Standards with a Comprehensive Checklist

A diligently applied construction quality control checklist template isn’t merely a document; it’s a strategic asset that underpins the entire construction process, guiding teams toward excellence at every turn. Its primary benefit lies in standardizing expectations and procedures across diverse project phases and various trades. This ensures that whether it’s the foundation being laid or the intricate electrical wiring being installed, every step is executed with precision and consistency, minimizing the potential for human error and fostering a culture of accountability.

Moreover, the proactive nature of a quality control checklist significantly reduces the likelihood of expensive reworks. By identifying potential issues early on, before they escalate into major problems, projects can avoid the time-consuming and budget-draining necessity of correcting mistakes post-completion. This early detection mechanism not only saves substantial amounts of money but also helps keep projects on schedule, preventing frustrating delays that can impact subsequent phases and stakeholder relationships.

Beyond just financial and scheduling benefits, these templates play a crucial role in ensuring safety and regulatory compliance. Construction sites are inherently complex environments with numerous safety protocols and building codes that must be rigorously followed. A comprehensive checklist incorporates these vital requirements, serving as a constant reminder and verification tool that all necessary safety measures are in place and that the structure complies with local, national, and industry-specific regulations, thereby protecting workers and future occupants alike.

Furthermore, a quality control checklist enhances communication channels within a project team and with external stakeholders. When expectations are clearly outlined and progress is systematically documented, it creates transparency. Everyone involved, from project managers to field workers, understands their responsibilities and the quality benchmarks they need to meet, making it easier to track progress, address concerns, and celebrate milestones effectively. This clarity minimizes misunderstandings and ensures everyone is working towards a unified vision of quality.

Ultimately, by integrating a construction quality control checklist template into your operational framework, you’re not just checking boxes; you’re building a foundation of trust, efficiency, and superior craftsmanship. It’s about creating a repeatable system that assures high quality from concept to completion, allowing you to consistently deliver projects that not only meet but exceed expectations.

Essential Sections for Your Template

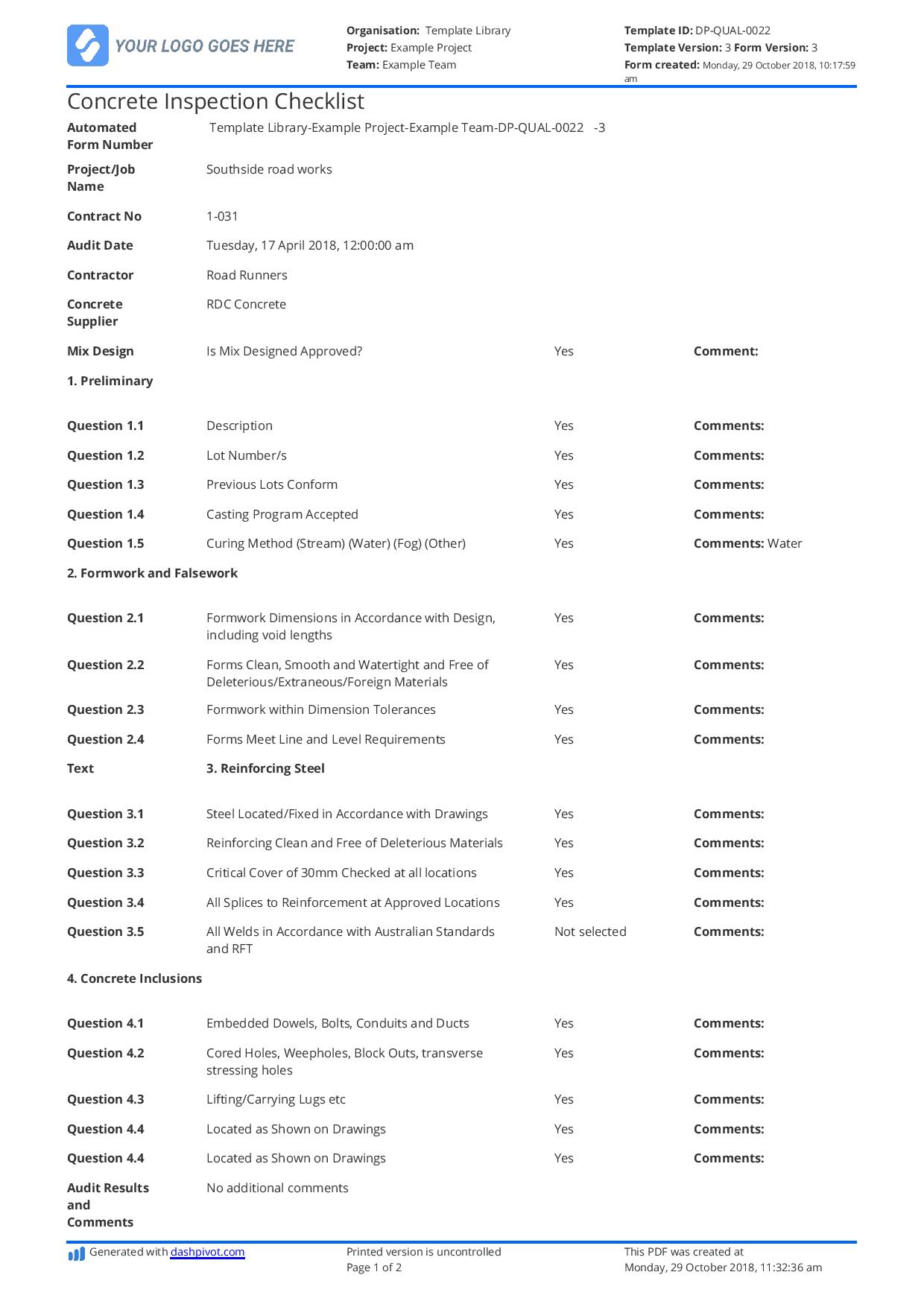

To be truly effective, your template should cover critical stages of construction. Consider including detailed sections such as:

* Site Preparation and Earthworks: Verifying excavation depths, soil compaction, and grading.

* Foundations and Structural Elements: Checking rebar placement, concrete pour quality, and structural integrity.

* Mechanical, Electrical, and Plumbing (MEP) Rough-ins: Ensuring correct installation, clearances, and code compliance for all systems.

* Framing and Building Envelope: Inspecting wall straightness, roof truss installation, and proper insulation and weatherproofing.

* Interior Finishes and Architectural Details: Assessing paint quality, flooring installation, cabinetry, and fixture placement.

* Final Inspections and Handover: Comprehensive checks before client walkthroughs, ensuring all systems are operational and finishes are perfect.

Customizing and Implementing Your Checklist for Optimal Results

While a generic construction quality control checklist template provides an excellent starting point, its true power is unlocked through customization and thoughtful implementation. No two construction projects are identical, and what works perfectly for a commercial high-rise might be overkill or insufficient for a residential renovation. Therefore, taking the time to adapt the template to the specific scope, size, complexity, and regulatory landscape of your project is crucial. This involves reviewing each item on the list and determining its relevance, adding new items specific to unique materials or techniques, and even removing those that don’t apply, ensuring the checklist remains practical and focused.

Successful implementation goes beyond just having a well-tailored document; it requires a strategic approach to integrating it into daily operations. This often begins with thorough training for all team members who will be using the checklist, ensuring they understand its purpose, how to properly complete it, and the importance of accurate documentation. Leveraging digital tools, such as project management software or specialized quality control apps, can significantly streamline the process, allowing for real-time updates, easy access on mobile devices, and centralized record-keeping that simplifies auditing and progress tracking.

Furthermore, assigning clear responsibilities for completing and reviewing checklist items is paramount. Every team member, from site supervisors to specialized trade workers, needs to know exactly what they are accountable for. Regular review meetings can also be beneficial, allowing teams to discuss observations, address any recurring issues, and share best practices. This collaborative approach fosters a sense of ownership and encourages everyone to actively participate in maintaining high quality standards.

Finally, consider your customized construction quality control checklist template as a living document that evolves with your company and projects. Establish a feedback loop where team members can suggest improvements or modifications based on their field experience. Regularly review the effectiveness of your checklist, perhaps after completing each major project, to identify areas for refinement. This commitment to continuous improvement ensures your quality control process remains relevant, efficient, and increasingly effective, contributing to an ongoing legacy of excellence in every build.

Embracing a robust quality control methodology, anchored by a well-utilized template, fundamentally transforms how construction projects are managed and delivered. It shifts the focus from reactive problem-solving to proactive prevention, fostering an environment where consistent high standards are the norm, not the exception. This deliberate approach not only safeguards your investment but also significantly enhances your reputation as a builder committed to delivering superior outcomes.

By consistently applying these principles, you’re not just constructing buildings; you’re building trust, efficiency, and a sustainable future for your business. The small effort invested in developing and implementing such a system pays dividends many times over, ensuring every project stands as a testament to your dedication to excellence.