In any workshop, job site, or even a home garage, hand tools are the unsung heroes that make projects happen. From hammers and screwdrivers to wrenches and pliers, these essential items are constantly put to work. While they might seem robust and straightforward, the truth is that even the simplest hand tool can become a hazard if it’s not properly maintained or inspected regularly.

Ensuring the safety and efficiency of your tools isn’t just about prolonging their lifespan; it’s fundamentally about protecting the people who use them. A damaged or faulty tool can lead to accidents, injuries, and significant delays in your work. That’s why having a systematic approach to tool care is paramount, and a reliable hand tools inspection checklist template can be your best friend in this endeavor.

Why Regular Hand Tool Inspections Are Crucial

Think about the sheer force a hammer withstands or the precision a screwdriver requires. Over time, constant use and even improper storage can take their toll on these hardworking items. A small crack in a handle, a worn-out grip, or a bent shaft might seem minor, but under stress, these seemingly insignificant flaws can quickly escalate into serious safety issues. Regular inspections help you catch these problems before they turn into accidents, protecting both the user and the integrity of the work being done.

Beyond the immediate safety concerns, neglecting tool inspections can lead to decreased productivity and increased costs. A tool that isn’t performing optimally will make tasks harder, slower, and potentially result in shoddy workmanship. Replacing tools frequently due to preventable wear and tear also adds up. A proactive approach, facilitated by a comprehensive inspection process, ultimately saves time, money, and prevents unnecessary frustration.

Key Areas to Focus On During Inspection

When you’re looking over your hand tools, it’s not just about a quick glance. A thorough inspection involves checking several critical components. Start with the general condition: look for any signs of rust, corrosion, or dirt buildup that could impair function or cause a slip hazard. Check for any missing parts, loose components, or unauthorized modifications that might compromise the tool’s original design and safety features.

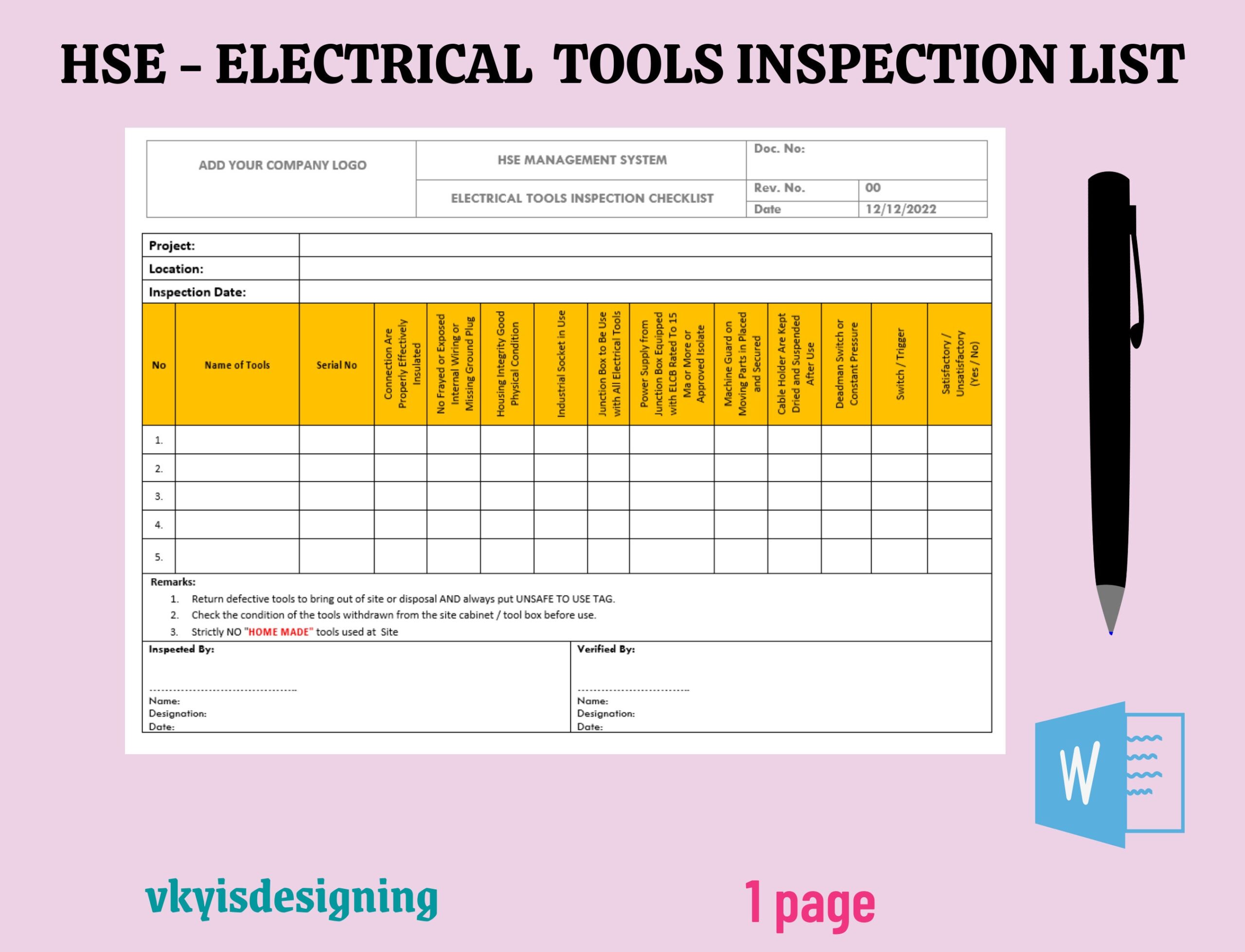

Specific attention should be paid to the business end of the tool and its handle. For striking tools like hammers, ensure the head is securely attached to the handle, and that there are no chips, cracks, or mushroomed edges on the striking face. For cutting tools, check the sharpness and integrity of the blade, making sure it’s not dull, bent, or chipped. Pliers and wrenches should be examined for jaw alignment, excessive play in moving parts, and any signs of stripped threads or deformed jaws. Insulated tools require an even closer look for any breaks or damage to the insulation, as this is crucial for electrical safety.

Handles and grips are also vital. They should be free from splinters, cracks, or any damage that could affect the user’s grip. Ensure that non-slip grips are intact and not excessively worn. The overall balance and feel of the tool should inspire confidence, not concern. Any tool that feels “off” should be immediately tagged for repair or replacement, removing it from circulation until it’s safe to use again.

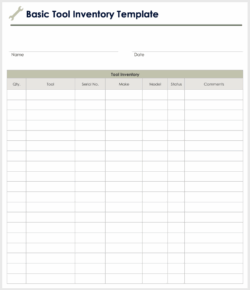

Building Your Effective Hand Tools Inspection Checklist Template

Creating your own robust hand tools inspection checklist template doesn’t have to be complicated, but it does need to be thorough and tailored to your specific needs and the types of tools you use most frequently. The goal is to provide a clear, step-by-step guide that even someone new to tool maintenance can easily follow. Start by categorizing your tools to make the checklist more manageable, perhaps by function (e.g., striking, cutting, gripping) or by location where they are stored.

A good checklist should prompt inspectors to look at common failure points. It’s essentially a reminder system to ensure no critical aspect is overlooked. Think about what goes wrong most often with your tools and build those specific checks into the template. Beyond just “pass” or “fail,” consider including a “repair/replace” column and a space for notes to document specific issues found.

- Inspect handles for cracks, splinters, or looseness.

- Check tool heads (hames, chisels) for mushrooming, chips, or secure attachment.

- Examine cutting edges (knives, snips) for sharpness, nicks, or bends.

- Look at jaws of wrenches and pliers for deformation, wear, or alignment issues.

- Test moving parts for smooth operation and excessive play.

- Verify insulation on electrical tools for damage or breaks.

- Clean tools and inspect for rust or corrosion.

- Ensure all safety guards or features are present and functional.

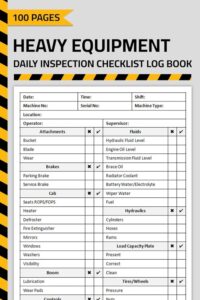

Remember that this isn’t a one-and-done process. The frequency of inspections will depend on how often your tools are used and the environment they’re exposed to. Tools used daily in harsh industrial settings will need more frequent checks than those used occasionally in a home workshop. Customizing your hand tools inspection checklist template with specific inspection intervals and responsibilities will ensure accountability and consistent safety standards.

Whether you opt for a physical clipboard checklist or a digital form on a tablet, the key is consistency and accurate record-keeping. Documenting inspections helps you track the condition of your tools over time, identify recurring issues, and demonstrate compliance with safety regulations. This historical data can also inform purchasing decisions, highlighting tools that might need more durable alternatives or better maintenance practices.

Implementing a routine for checking your hand tools is a small effort that yields significant returns in terms of safety, efficiency, and longevity. It transforms a potentially reactive approach to tool management into a proactive one, where problems are identified and addressed before they can cause harm or hinder progress. By embedding these checks into your daily or weekly routine, you foster a culture of vigilance and care.

Ultimately, a well-maintained set of hand tools is a safer, more productive set of tools. Taking the time to regularly inspect and care for these essential items protects not only your equipment investment but, more importantly, the well-being of everyone who uses them. It’s an investment in uninterrupted work and a safer environment for all.