Ensuring safety in any workplace that utilizes heavy machinery is paramount, and when it comes to lifting operations, the stakes are incredibly high. From construction sites to manufacturing plants, the proper functioning and maintenance of lifting equipment are not just about efficiency; they are fundamentally about preventing accidents, injuries, and even fatalities. Regular, thorough inspections are the backbone of a safe lifting environment, providing a critical safeguard against potential failures.

However, conducting these inspections haphazardly simply won’t cut it. To be truly effective, inspections need to be systematic, comprehensive, and meticulously documented. This is where a structured approach becomes invaluable, transforming a potentially overlooked task into a vital component of your safety protocol. A well-designed checklist provides the framework necessary to ensure that every crucial detail is examined, nothing is missed, and compliance standards are consistently met.

Why Regular Inspections are Non-Negotiable for Lifting Equipment Safety

Operating lifting equipment, whether it is a forklift, crane, hoist, or sling, carries inherent risks that can only be mitigated through diligent safety practices. The sheer power and weight involved mean that even a minor defect or oversight can have catastrophic consequences, leading to severe damage to property, significant operational downtime, and most tragically, serious injuries or loss of life. Proactive inspection is the shield against such devastating outcomes, turning potential hazards into identifiable issues that can be addressed before they escalate.

Beyond the immediate safety concerns, businesses also face stringent legal and regulatory obligations regarding the maintenance and inspection of lifting equipment. Governing bodies worldwide impose strict standards to protect workers. Failure to comply with these regulations can result in heavy fines, legal action, and a severely damaged reputation, all of which can have long-lasting negative impacts on an organization. Regular, documented inspections provide irrefutable evidence of your commitment to these legal requirements.

Moreover, routine inspections play a crucial role in extending the lifespan of your valuable assets. By identifying wear and tear early on, you can schedule preventative maintenance, addressing small problems before they morph into major, costly repairs or necessitate premature equipment replacement. This proactive approach saves money in the long run by minimizing unexpected breakdowns and maximizing the operational efficiency of your machinery. It transforms maintenance from a reactive expense into a strategic investment.

Key Areas of Focus During Inspection

- **Structural Integrity:** Checking for cracks, deformations, corrosion, or weld defects on load-bearing components.

- **Operational Controls:** Ensuring all buttons, levers, and joysticks respond correctly and are clearly labeled.

- **Safety Devices:** Verifying the functionality of limit switches, emergency stops, overload protection, and warning alarms.

- **Ropes, Chains, and Slings:** Inspecting for fraying, kinks, broken wires, excessive wear, or deformation.

- **Fluid Levels and Leaks:** Checking hydraulic fluid, oil, and coolant levels, and looking for any signs of leakage.

Ultimately, safety culture starts at the top and permeates every level of an organization. Empowering employees with the tools and knowledge to conduct thorough inspections fosters a collective responsibility for safety. When everyone understands the importance of each step in the inspection process, it creates an environment where vigilance is prioritized, and potential risks are systematically identified and reported. This collective effort is instrumental in maintaining an accident-free workplace. The consistent application of a comprehensive lifting equipment inspection checklist template ensures that this systematic vigilance is embedded into daily operations, leaving no stone unturned in the pursuit of safety excellence.

Crafting Your Own Effective Lifting Equipment Inspection Checklist Template

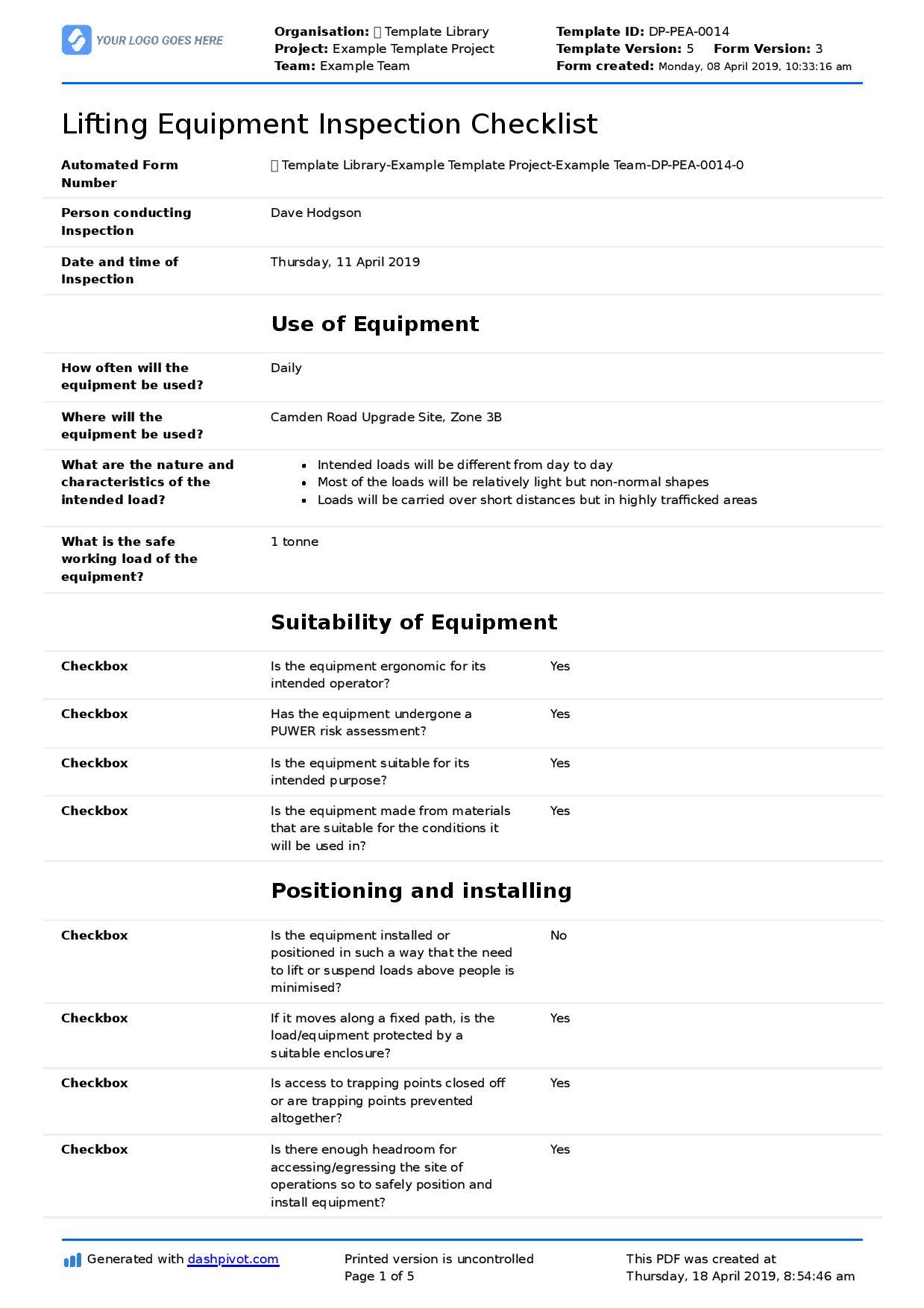

While many generic templates are available, the most effective inspection checklist will always be one tailored to your specific equipment, operational environment, and regulatory landscape. Generic lists are a good starting point, but customization is key. Every piece of lifting equipment has unique features, potential failure points, and operational nuances that must be thoroughly addressed. Taking the time to build a specific template ensures that the inspection accurately reflects the actual risks and requirements of your machinery.

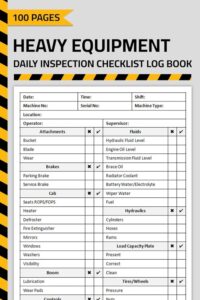

A truly robust template goes beyond a simple yes/no questionnaire. It should prompt detailed observations, allow for comments on the condition of components, and specify the actions to be taken if a defect is found. It also needs to be user-friendly, clear, and concise, making it easy for inspectors to follow without ambiguity. Complexity can lead to errors or overlooked items, undermining the very purpose of the checklist. The goal is to empower the inspector to conduct a thorough evaluation efficiently.

Essential components to include in your lifting equipment inspection checklist template:

- **Equipment Identification:** Make and model, serial number, unique asset ID.

- **Date and Time of Inspection:** Critical for record-keeping and tracking frequency.

- **Inspector’s Name and Signature:** Accountability is key.

- **Pre-Operational Checks:** Visual inspection before use (e.g., general condition, tires, fluid levels).

- **Functional Tests:** Verifying controls, brakes, warning systems, and lifting mechanisms.

- **Specific Component Checks:** Detailed examination of ropes, chains, hooks, slings, structural elements, and safety devices.

- **Defect Reporting:** Clear sections for noting any identified faults, their severity, and immediate actions.

- **Post-Operational Checks:** Visual inspection after use to note any new damage or issues.

- **Maintenance History Reference:** A space to note when the last full service or major repair was conducted.

- **Overall Assessment and Sign-off:** A final determination of the equipment’s fitness for use.

Regularly reviewing and updating your inspection template is also crucial. As equipment ages, new regulations emerge, or operational processes change, your checklist should evolve to remain relevant and effective. Involving the operators and maintenance personnel in this review process can provide invaluable insights, ensuring the template addresses real-world challenges and covers all critical aspects. A living document that adapts to changing circumstances will always be more effective than a static one.

Adopting a comprehensive and customized lifting equipment inspection checklist template is more than just fulfilling a compliance requirement; it is a strategic investment in the safety, efficiency, and longevity of your operations. It fosters a culture of diligence and accountability, significantly reducing the potential for accidents and costly downtime. By standardizing your inspection processes, you equip your team with a powerful tool for proactive risk management.

Investing in a rigorous inspection regime, underpinned by a well-structured template, pays dividends in worker safety and operational reliability. It’s a testament to a company’s commitment to preventing incidents rather than merely reacting to them. By systematically verifying the integrity of your lifting equipment, you create a safer working environment for everyone, ensuring that every lift is executed with confidence and security.