Navigating the complexities of modern manufacturing can often feel like a tightrope walk. Every step of the production process, from sourcing raw materials to final packaging, presents an opportunity for something to go awry. Without a clear system in place, minor inconsistencies can quickly escalate into significant defects, leading to costly rework, missed deadlines, and ultimately, unhappy customers. This is where the strategic implementation of robust quality control measures becomes not just an advantage, but an absolute necessity for any operation striving for excellence and efficiency.

Imagine a world where every product leaving your facility consistently meets the highest standards. This vision isn’t just a pipe dream; it’s an achievable reality when you equip your team with the right tools. A well-designed quality control checklist acts as your company’s vigilant guardian, ensuring that every critical step is thoroughly inspected and verified. It standardizes procedures, minimizes human error, and provides an invaluable record for continuous improvement, making your entire manufacturing process more reliable and predictable.

The Indispensable Role of a Structured Quality Control Framework

In today’s competitive manufacturing landscape, simply making a product isn’t enough. It’s about consistently making a quality product. This pursuit of excellence requires a systematic approach, one that leaves no stone unturned in the production journey. A structured quality control framework, often anchored by a comprehensive manufacturing quality control checklist template, serves as the backbone for achieving this consistency and reliability. It’s more than just a list of items to check off; it’s a living document that drives accountability, fosters a culture of quality, and safeguards your brand’s reputation.

Think about the ripple effect of a single defective product reaching the market. It can erode customer trust, lead to expensive recalls, and tarnish years of brand building. Conversely, consistently delivering high-quality goods builds loyalty and word-of-mouth referrals, becoming a powerful engine for growth. A robust quality control system, therefore, isn’t an overhead; it’s a critical investment that yields significant returns in customer satisfaction and long-term profitability. It empowers your team to identify and rectify issues at the earliest possible stage, preventing small problems from spiraling into major crises down the line.

Ensuring Unwavering Product Consistency

One of the primary benefits of a well-defined quality control structure is the ability to maintain unwavering product consistency. Customers expect the same level of quality every single time they purchase your product. A detailed checklist helps standardize inspection points, measurement criteria, and testing protocols across all shifts and all operators. This removes subjectivity and ensures that every item produced adheres to the same stringent specifications, regardless of who is performing the check or when. It’s about building a predictable and reliable outcome.

Minimizing Rework and Waste

Defects discovered late in the production cycle, or worse, after shipment, are incredibly costly. They involve not only the expense of raw materials and labor for the initial faulty item but also the additional cost of rework, scrap, or even product returns. By integrating a quality control checklist at critical stages, you can catch errors early. Imagine identifying a calibration issue with a machine before it has produced hundreds of defective units, or spotting a material flaw before it’s been integrated into a complex assembly. This proactive approach significantly reduces waste and the expensive inefficiencies associated with rectifying post-production problems, directly impacting your bottom line.

Boosting Customer Satisfaction and Loyalty

Ultimately, the true measure of quality control lies in customer satisfaction. When customers consistently receive products that meet or exceed their expectations, their trust in your brand grows. This trust translates into repeat business, positive reviews, and a stronger market position. A manufacturing quality control checklist template directly contributes to this by ensuring that every product leaving your facility is fit for purpose and free from flaws. It’s about delivering on your promise of quality every single time, fostering a loyal customer base that champions your brand.

Crafting an Effective Manufacturing Quality Control Checklist Template

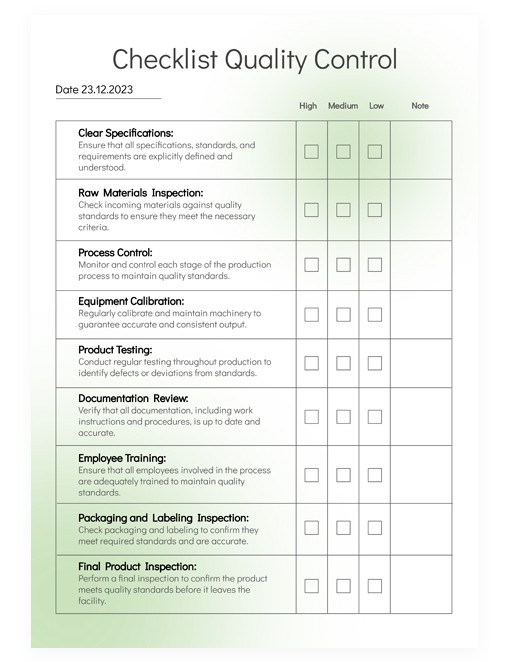

Building an effective manufacturing quality control checklist template isn’t just about listing a few items; it’s about meticulously dissecting your entire production process to identify every critical juncture where quality can be assured or compromised. This comprehensive approach ensures that every aspect, from the incoming raw materials to the final product leaving the warehouse, is subject to rigorous scrutiny. A well-designed template serves as a dynamic tool, adaptable to various products and production lines, while maintaining the core principles of thoroughness and clarity.

The power of a truly effective checklist lies in its ability to be both exhaustive and easy to use. It should guide inspectors through each step logically, using clear language and measurable criteria. This prevents ambiguity and ensures that different team members interpret and execute checks in the same way, thereby maintaining standardization across the board. The goal is to empower your quality control team with a document that simplifies complex tasks, making adherence to quality standards second nature rather than an arduous chore.

When developing your checklist, consider breaking it down into distinct phases of the manufacturing process. This segmentation allows for focused inspections and helps to pinpoint where issues might be originating. For instance, checks for incoming materials will differ vastly from those applied during final assembly or packaging, and organizing them logically makes the entire process more manageable and efficient for your team. Regularly reviewing and updating the template based on feedback and new product specifications is also crucial for its continued efficacy.

A well-structured template will not only outline what needs to be checked but also how, by whom, and when. It provides a historical record of inspections, allowing for traceability and helping to identify trends or recurring issues that might require deeper investigation. This data-driven approach transforms quality control from a reactive measure into a proactive strategy for continuous improvement, constantly refining your processes and elevating your product quality to new heights.

Here are some key elements you should consider integrating into your template:

- Raw Material Inspection:

- Verify quantity and correct material type against purchase orders.

- Check for visible damage, defects, or contamination.

- Confirm material specifications, certifications, and compliance documents.

- Test samples for critical properties as needed (e.g., strength, purity).

- In-Process Production Checks:

- Confirm machine setup and calibration before each run.

- Monitor critical dimensions and tolerances at various stages.

- Inspect for assembly accuracy and proper component placement.

- Verify adherence to specific process parameters (e.g., temperature, pressure).

- Conduct visual inspections for blemishes, scratches, or inconsistencies.

- Post-Production and Final Inspection:

- Perform full functional testing of the finished product.

- Inspect for overall aesthetic quality and finish.

- Verify proper labeling, branding, and user manual inclusion.

- Check packaging integrity, protective materials, and shipping marks.

- Confirm final quantity count and documentation for shipment.

- Documentation and Reporting:

- Fields for inspector’s name, date, time, and shift.

- Space for detailed notes on any identified non-conformities.

- Severity classification for defects (minor, major, critical).

- Action taken section for corrective measures.

- Sign-off sections for supervisors or quality managers.

Embracing a well-crafted quality control checklist is more than just an administrative task; it’s about embedding a culture of vigilance and precision throughout your entire manufacturing operation. By systematically verifying every crucial detail, you empower your team to not only meet but consistently exceed quality standards. This proactive approach ensures that every product leaving your facility contributes positively to your brand’s reputation and customer trust.

The journey to manufacturing excellence is continuous, and a robust quality control framework provides the essential roadmap. It allows you to consistently deliver products that resonate with quality, build enduring customer relationships, and establish your brand as a leader in its field.