Ever found yourself rummaging through a cluttered toolbox, desperately searching for that one specific wrench while a customer waits or a DIY project stalls? It’s a common frustration for mechanics, whether professional or enthusiastic hobbyists. The time wasted searching for tools can add up quickly, not to mention the annoyance of discovering a tool is missing right when you need it most. A disorganized workspace isn’t just inefficient; it can also be costly, leading to duplicate purchases or lost valuable equipment.

This is where a robust system comes into play. Imagine a world where every tool has its place, and you know exactly what you own at a glance. That’s the power of an effective tool management strategy, and at its heart lies a well-structured mechanic tool inventory list template. This isn’t just about making a list; it’s about creating an asset register that brings order, saves time, and prevents financial losses due to misplaced or forgotten equipment.

Whether you run a bustling auto repair shop, manage a fleet maintenance department, or simply take pride in your home garage setup, implementing a systematic approach to tool tracking can revolutionize your workflow. It’s a foundational step towards optimizing operations, enhancing accountability, and ultimately, boosting productivity for anyone who relies on a diverse set of tools to get the job done right.The Foundation of an Organized Workshop: What to Include in Your Tool Inventory

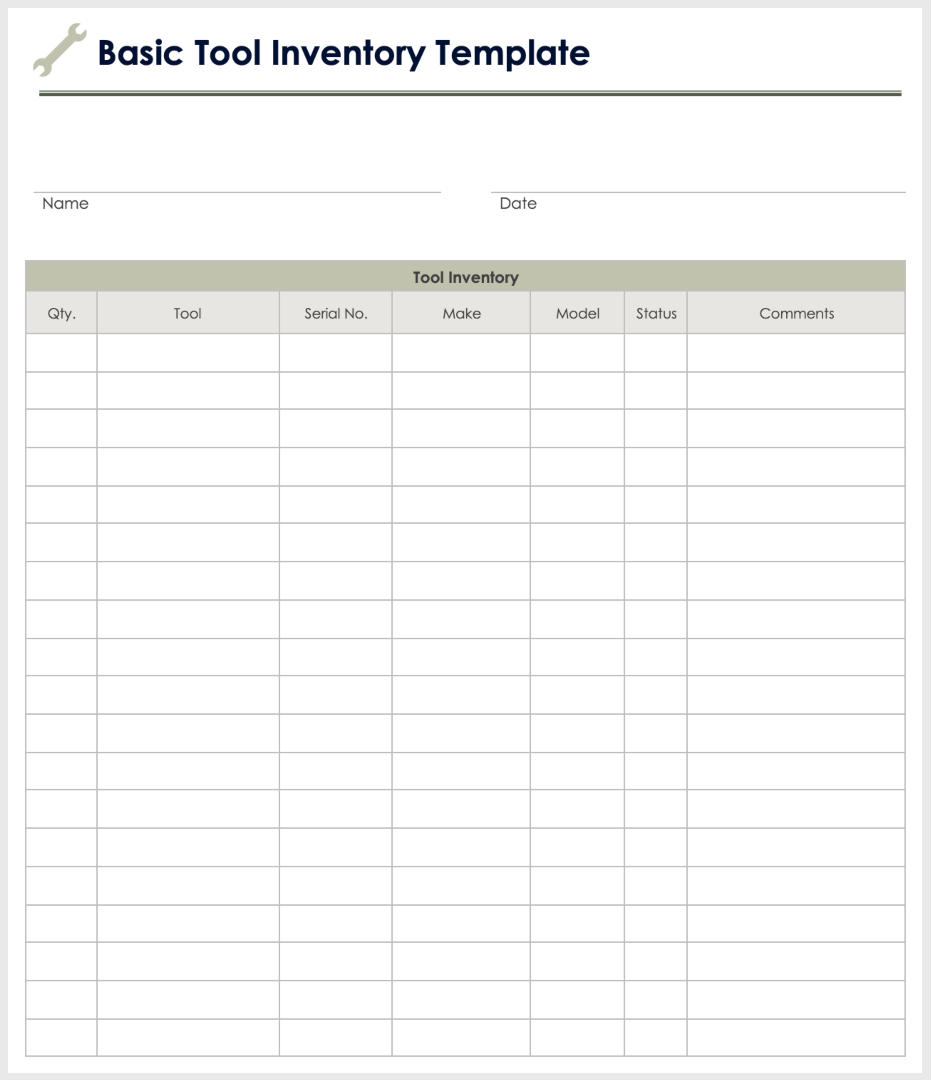

Building a comprehensive tool inventory goes far beyond a simple headcount of your wrenches and screwdrivers. It’s about creating a detailed record of every single item that contributes to your mechanical work, ensuring you can quickly identify what you have, its condition, and where it should be stored. This level of detail is invaluable for insurance purposes, tracking depreciation, scheduling maintenance, and even for identifying tools that might be prone to “walking away.” Think of it as the ultimate blueprint for your workshop’s assets, providing peace of mind and operational clarity.

When you start populating your mechanic tool inventory list template, a logical approach is to categorize your tools. This makes the list easier to navigate and update. Start with the most frequently used items that form the backbone of everyday tasks: your general hand tools. These are the workhorses that see constant action and are often the first to go missing or get misplaced in the heat of a job.

Within the hand tools category, it’s beneficial to break it down further. Be specific. Instead of just “wrenches,” list the types and sizes. This granular detail ensures that if you need a specific 13mm ratcheting wrench, you know if you have one and precisely where it’s kept.

Essential Hand Tools

- Socket Sets (Metric and SAE, various drives)

- Wrench Sets (Combination, open-end, box-end, ratcheting, flare-nut)

- Screwdriver Sets (Flathead, Phillips, Torx, Hex)

- Pliers (Needle-nose, slip-joint, locking, cutting)

- Hammers (Ball-peen, rubber mallet, dead blow)

- Chisels and Punches

- Pry Bars and Breaker Bars

Next up are the more specialized and often higher-value items: power tools and diagnostic equipment. These tools represent a significant investment and their absence can bring a job to a complete halt. Tracking their serial numbers, purchase dates, and even their last service date is crucial for both security and maintenance planning. This section often includes items that require specific chargers or accessories, which should also be noted.

Specialized and Power Tools

- Impact Wrenches (Corded, cordless, air-powered)

- Drills (Corded, cordless, hammer drills)

- Grinders (Angle grinders, bench grinders)

- Diagnostic Scanners and OBD-II Readers

- Air Tools (Die grinders, sanders, air hammers)

- Battery Chargers and Spare Batteries

- Hydraulic Jacks and Jack Stands

- Vehicle Lifts and specialized hoists

Finally, don’t overlook the smaller but equally important items, often grouped as consumables or safety gear. While they might not have a high individual cost, their collective expense and importance to safety and efficiency make them vital inclusions. These are the items that often get used up, misplaced, or simply overlooked during a quick inventory check. Having them on your list helps with reordering and ensuring you never run out mid-task.

- Personal Protective Equipment (Safety glasses, gloves, ear protection, respirators)

- Shop Rags and Wipes

- Lubricants, Greases, and Specialty Fluids

- Fasteners (Nuts, bolts, washers, rivets)

- Cutting Discs, Grinding Wheels, and Drill Bits

For each item, consider adding columns for quantity, brand, model number, serial number, purchase date, cost, current condition, and its designated storage location. This level of detail transforms a simple list into a powerful asset management tool, allowing for quick retrieval and informed decisions about replacements or upgrades.

Beyond the List: Maximizing Your Template’s Potential

Creating a mechanic tool inventory list template is an excellent first step, but its true power is unleashed through consistent application and regular maintenance. It’s not just a document to create and forget; it’s a living guide that should evolve with your workshop. Integrating this list into your daily operations transforms it from a static record into an active tool management system that saves you time and money on an ongoing basis.

One of the most effective ways to maximize your template’s potential is through regular audits. Schedule quarterly or semi-annual checks to compare your physical inventory against your list. This helps identify missing tools, note tools that are damaged or need replacement, and update locations if your shop layout changes. This proactive approach prevents small discrepancies from turning into major headaches and ensures your list remains accurate and reliable.

Furthermore, consider how your inventory template can inform your storage solutions. Tools are less likely to go missing when they have a clearly designated home. Using shadow boards, custom drawer inserts, or labeled toolboxes that correspond to your inventory list can drastically improve efficiency. When every tool has a “parking spot,” it’s instantly noticeable when something is out of place, making returns and accountability much easier to manage.

- **Regular Audits and Updates:** Schedule periodic checks to match your physical tools with your inventory list.

- **Designated Storage Locations:** Assign a specific home for each tool and note it on your template.

- **Digital Backup Options:** Store your template in the cloud or on a shared drive for easy access and collaboration.

Adopting a comprehensive tool inventory system is more than just an organizational chore; it’s a strategic investment in efficiency and asset protection. By meticulously cataloging your equipment, from the smallest hex key to the most advanced diagnostic scanner, you lay the groundwork for a seamlessly operating environment. This proactive approach drastically reduces wasted time spent searching, minimizes the financial burden of lost or duplicated purchases, and enhances the overall professionalism of your workspace.

Ultimately, a well-maintained tool inventory liberates you to focus on the intricate work at hand, rather than the mundane task of tool recovery. It provides a clear overview of your assets, empowers better decision-making regarding purchases and maintenance, and fosters a sense of order that permeates throughout your operations. Taking the time to implement such a system today will undoubtedly pay dividends in productivity and peace of mind for years to come.