In the dynamic world of manufacturing, precision and clarity are paramount. Every product, from a simple gadget to a complex machine, is an assembly of countless parts and components. Keeping track of all these elements, understanding their relationships, and ensuring their availability is a monumental task that can make or break a production run. This is where the concept of a Bill of Materials, or BOM, becomes not just useful, but absolutely essential for any successful manufacturing operation.

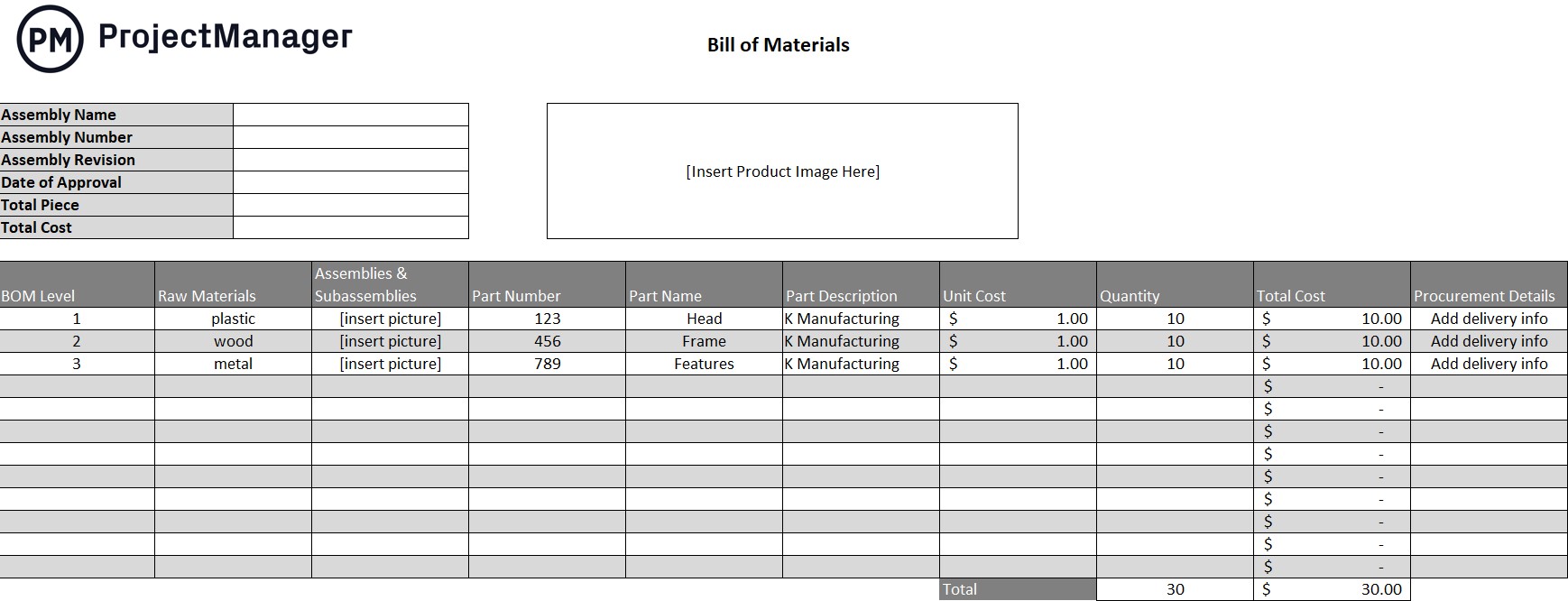

A well-structured Bill of Materials serves as the blueprint for your product, detailing every single item required to build it from start to finish. However, creating and managing these intricate lists can be time-consuming and prone to errors if done manually or inconsistently. This is precisely why having a dedicated manufacturing bill of materials template can be a game-changer, transforming a potentially chaotic process into a streamlined and highly efficient one.

What is a Manufacturing Bill of Materials and Why Do You Need a Template?

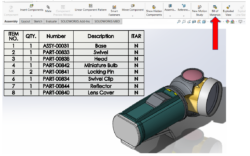

At its core, a Manufacturing Bill of Materials (BOM) is an exhaustive list of all the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product. Think of it as the recipe for your product, guiding your production team through every step. It’s not just a list; it’s a living document that dictates everything from procurement to final assembly, ensuring that every piece fits perfectly and the final product meets its specifications.

The need for a robust BOM extends far beyond simply listing parts. It’s critical for accurate cost estimation, as it provides a clear breakdown of material costs. It’s indispensable for inventory management, allowing you to track what you have, what you need to order, and when. For production planning, the BOM helps schedule tasks and allocate resources efficiently. Furthermore, it plays a vital role in quality control, ensuring that only approved and correct components are used, and in regulatory compliance, providing traceability for all parts. Without a clear and comprehensive BOM, you risk production delays, material shortages, cost overruns, and even product recalls.

Key Elements of a Robust BOM

- Part Number: A unique numerical or alphanumeric identifier for each component. This ensures precision and avoids confusion between similar parts.

- Part Name: A clear, descriptive name that instantly tells you what the item is.

- Description: Additional details about the component, such as material, size, color, or specific characteristics that differentiate it from similar items.

- Quantity: The exact number of units of each component required for one unit of the final product. Accuracy here is crucial for avoiding shortages or excess.

- Unit of Measure: How the quantity is measured, e.g., pieces, meters, kilograms, liters.

- Procurement Type: Indicates whether the component is manufactured in-house (“make”) or purchased from an external supplier (“buy”).

- Revision Level: A version number or identifier that tracks changes made to the BOM over time, ensuring everyone is working with the most current specifications.

Utilizing a manufacturing bill of materials template helps you consistently capture all these crucial data points. It provides a standardized framework, reducing the chances of overlooking critical information and ensuring that every BOM created across your organization follows the same format and includes all necessary fields. This consistency is key to minimizing errors, streamlining communication between departments, and ultimately, boosting overall operational efficiency.

Choosing and Using Your Manufacturing Bill of Materials Template

When it comes to selecting the right manufacturing bill of materials template, you’ll find a range of options, from simple spreadsheet-based solutions to more integrated templates designed for enterprise resource planning (ERP) systems. The best choice for your operation often depends on the complexity of your products, the scale of your production, and your existing software infrastructure. For smaller operations or less complex products, a well-designed Excel or Google Sheets template might suffice, offering flexibility and ease of use. Larger companies with intricate products and higher volumes will likely benefit from templates integrated within a dedicated BOM management software or an ERP system, which can handle complex relationships, automate calculations, and provide real-time updates across multiple departments.

A good template should be intuitive and easy to populate, minimizing the learning curve for your team. Look for clear column headers, designated fields for each piece of information (part number, quantity, unit of measure, etc.), and perhaps even built-in validation rules to prevent common data entry errors. The template should also be flexible enough to accommodate different product types and allow for customization as your products evolve. Features like the ability to link to component specifications, supplier information, or CAD drawings can add significant value, centralizing all relevant product data in one accessible place.

Effectively using your chosen template involves more than just filling in the blanks. It requires a disciplined approach to data entry, ensuring that information is consistent, accurate, and up-to-date. Establish clear protocols for who is responsible for creating, reviewing, and approving BOMs. Regular audits of your BOMs against actual production and inventory records can help identify discrepancies and ensure accuracy. Encouraging collaboration between engineering, purchasing, and production teams is also vital, as each department contributes unique insights and relies on the BOM for their specific functions.

The long-term benefits of a meticulously maintained manufacturing bill of materials template are substantial. You’ll experience improved inventory accuracy, leading to fewer stockouts and reduced carrying costs. Production planning becomes more precise, minimizing delays and maximizing throughput. Cost control improves significantly as you gain a clearer picture of material expenses and can identify opportunities for cost reduction. Ultimately, a well-managed BOM supports faster product development cycles, higher product quality, and greater overall profitability, laying a solid foundation for sustainable growth and operational excellence in your manufacturing endeavors.

Harnessing the power of a comprehensive and accurate Bill of Materials is no longer a luxury but a fundamental requirement for modern manufacturers aiming for efficiency and competitive advantage. It serves as the single source of truth for all product-related information, ensuring that every department, from design to delivery, is working with the same, precise data. This level of clarity and control is invaluable, helping to prevent costly mistakes and accelerate your production processes.

By thoughtfully implementing and diligently maintaining a robust Bill of Materials system, supported by an effective template, you empower your team with the insights needed to make informed decisions. This proactive approach to managing your product’s DNA not only optimizes your current operations but also positions your business for future innovation and success, enabling you to bring high-quality products to market with greater speed and confidence.