In the intricate world of engineering and product development, bringing an idea from concept to reality is a journey filled with countless details. One crucial element that acts as the backbone for this entire process is the Bill of Materials, often simply called a BOM. It’s essentially a comprehensive list of all the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product. Without a properly managed BOM, even the most innovative designs can lead to production nightmares, budget overruns, and missed deadlines.

Imagine trying to bake a complex cake without a recipe; you’d likely forget an ingredient, add too much of another, and end up with something far from your desired outcome. An engineering BOM acts as that precise recipe for your product, ensuring every component is accounted for and that the assembly process flows smoothly. This is precisely why having a robust engineering bill of materials template isn’t just a nice-to-have; it’s a fundamental necessity for any successful engineering project, large or small.

Why an Engineering Bill of Materials Template is Your Project’s Best Friend

Modern engineering projects, whether they involve intricate electronics, complex machinery, or innovative consumer goods, demand precision and coordination. The sheer volume of parts, suppliers, and processes involved can quickly become overwhelming. This is where a well-designed engineering bill of materials template steps in, transforming potential chaos into structured order. It provides a standardized framework, ensuring that every piece of information related to your product’s components is captured consistently and accurately.

The benefits of adopting such a template are multifaceted. Firstly, it drastically improves accuracy. By having predefined fields for part numbers, descriptions, quantities, and more, the likelihood of human error in data entry is significantly reduced. This accuracy translates directly into fewer manufacturing mistakes, less material wastage, and a smoother production line. Secondly, a template saves an immense amount of time. Instead of creating a new BOM from scratch for every project, you can simply populate the existing template, allowing your team to focus on engineering challenges rather than administrative tasks.

Furthermore, an effective template is indispensable for critical aspects like cost estimation and procurement. With a clear breakdown of all required components and their quantities, you can quickly generate accurate cost projections, aiding in budgeting and pricing decisions. Procurement teams can leverage this standardized data to efficiently order the right parts from the right suppliers at the right time, preventing costly delays or overstocking. It also streamlines inventory management, giving you a real-time snapshot of what you have and what you need.

Beyond the immediate financial and operational benefits, a well-implemented engineering bill of materials template fosters better collaboration across departments. Engineers, purchasing agents, manufacturing specialists, and even sales teams can all work from a single, consistent source of truth. This shared understanding minimizes miscommunications and ensures that everyone is aligned on the product’s composition, revisions, and production requirements, ultimately leading to faster time-to-market and higher quality products.

Key Components You’ll Find in a Robust Template

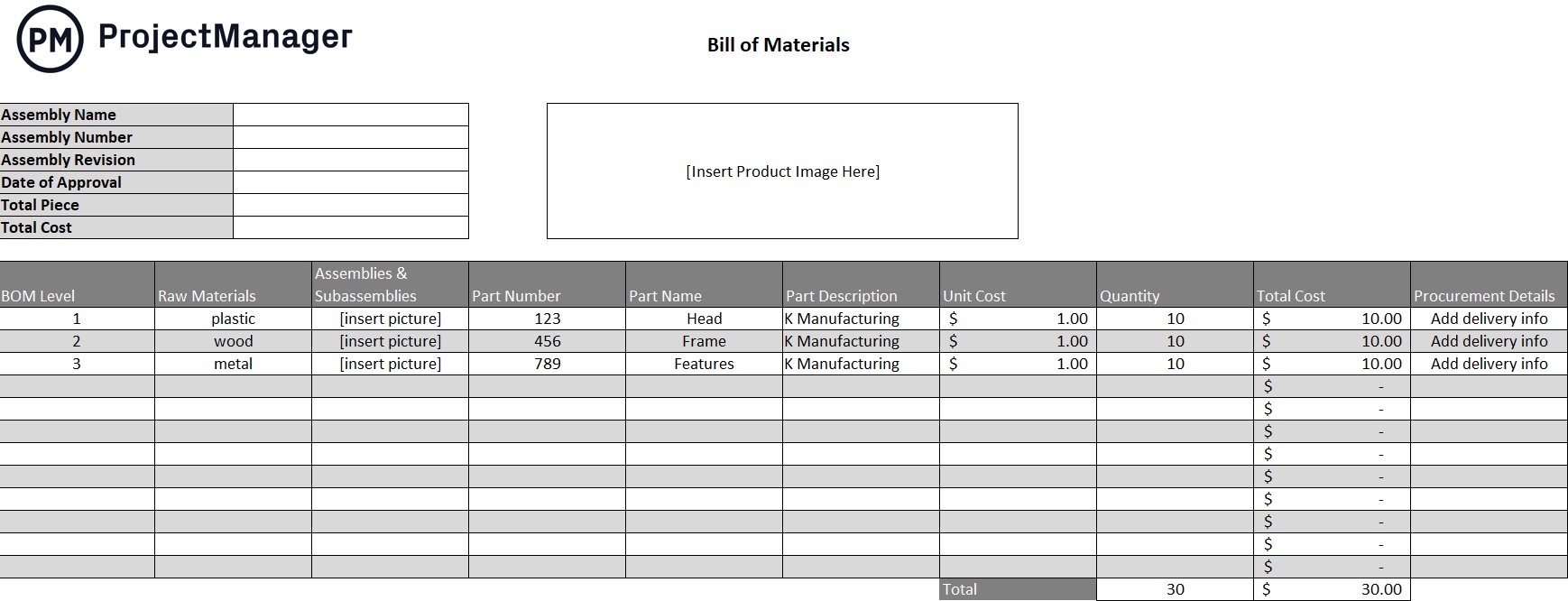

While specific needs may vary, most comprehensive engineering bill of materials templates include several core data fields:

- Part Number: A unique identifier for each component.

- Part Name/Description: A clear, descriptive name for the component.

- Quantity: The number of units of each component required for one end product.

- Unit of Measure: How the quantity is measured (e.g., pieces, meters, grams).

- Manufacturer: The company that produces the specific part.

- Manufacturer Part Number: The manufacturer’s unique identifier for their part.

- Cost per Unit: The cost of a single unit of the component.

- Total Cost: Quantity multiplied by cost per unit.

- Lead Time: The time required to obtain the component from the supplier.

- Revision Level: Tracks changes made to the component or assembly.

- Notes/Comments: Any additional relevant information, such as assembly instructions or special handling.

These fields are crucial because they provide a holistic view of each component, enabling detailed planning and execution throughout the product lifecycle. A template that consistently captures this data makes every subsequent process, from sourcing to assembly, significantly more efficient and less prone to error.

Crafting Your Perfect Engineering Bill of Materials Template

Creating or customizing an engineering bill of materials template that truly serves your specific needs requires a thoughtful approach. While many generic templates are available, the most effective ones are often tailored to the unique complexities and workflows of your organization and the types of products you develop. Start by identifying the core information your team consistently needs for every component, then build out from there, adding fields that address your particular requirements for quality control, compliance, or even specific supplier relationships.

When it comes to the medium for your template, you have several options. For smaller projects or startups, a well-structured spreadsheet program like Microsoft Excel or Google Sheets can be a surprisingly powerful tool. They offer flexibility in customization, ease of sharing, and widely understood functionalities. However, as projects grow in complexity and the number of components escalates, many companies transition to specialized Bill of Materials software or Product Lifecycle Management (PLM) systems. These dedicated platforms offer advanced features like automated revision control, integration with CAD software, and robust multi-user collaboration, which can be invaluable for large-scale operations.

Regardless of the platform you choose, adhering to best practices is paramount. Consistency in naming conventions across all parts and assemblies is vital for preventing confusion and ensuring accurate data retrieval. Implementing a clear and robust revision control system within your template is non-negotiable; without it, you risk manufacturing outdated versions of products or ordering incorrect components. Furthermore, ensure that the template is accessible to all relevant stakeholders—engineering, purchasing, manufacturing, and even quality assurance—and that they are trained on its proper use. This collective ownership reinforces its effectiveness.

Investing time upfront in designing and refining your engineering bill of materials template is an investment that pays dividends many times over. It dramatically reduces the likelihood of costly errors, streamlines communication between departments, and accelerates the entire product development cycle. By providing a clear, accurate, and easily understandable blueprint for every product, you empower your team to operate with greater efficiency, precision, and confidence, leading to successful product launches and sustained growth.

Ultimately, a well-structured Bill of Materials isn’t just a document; it’s a strategic asset that orchestrates the entire production process. By adopting and diligently utilizing a comprehensive template, you lay a solid foundation for operational excellence. This proactive approach minimizes risks, optimizes resource allocation, and ensures that every component aligns perfectly with your design intent.

Embracing such a standardized tool empowers your engineering team to transform complex designs into tangible products with unparalleled efficiency. It fosters a disciplined environment where precision and clarity reign supreme, ultimately leading to higher quality products, reduced time to market, and a significant competitive advantage in today’s fast-paced industrial landscape.