Embarking on any construction project, big or small, involves a myriad of details, from structural blueprints to managing a bustling workforce. Yet, among the most critical documents that often determine a project’s financial health and timely completion is the Bill of Materials, or BOM. Think of it as the complete shopping list for your build, meticulously detailing every single item, component, and material needed from the first shovel of dirt to the final coat of paint. It’s the backbone of accurate budgeting, procurement, and inventory management, ensuring nothing is overlooked.

Without a precise BOM, construction projects can quickly fall prey to cost overruns, material shortages, and frustrating delays. Imagine halting work because you underestimated the amount of rebar or forgot to order specific electrical conduits. This is where a well-structured Bill of Materials comes into play, providing clarity and control over your resources. It’s not just a list; it’s a strategic tool designed to streamline your operations and minimize wasteful spending, setting a solid foundation for success.

The Crucial Role of a Bill of Materials in Construction

A Bill of Materials in construction is far more than just an inventory checklist; it’s a foundational document that underpins the entire project lifecycle. It provides a comprehensive, itemized list of every component, raw material, and sub-assembly required to complete a construction job. This meticulous detail allows project managers to accurately estimate costs, plan procurement schedules, and allocate resources efficiently. Without this granular level of information, predicting expenses and avoiding material wastage becomes a challenging, often impossible, task, leading to budget blowouts and unforeseen delays.

One of the primary benefits of a detailed BOM is its direct impact on cost control and budgeting. By knowing precisely what materials are needed and in what quantities, you can solicit accurate quotes from suppliers, compare prices effectively, and negotiate better deals. This proactive approach helps prevent overspending and ensures that your financial estimates are as close to reality as possible. Furthermore, it allows for better cash flow management, as you can plan material purchases according to the project timeline rather than making reactive, last-minute orders that often come with premium prices.

Key Elements of an Effective Construction BOM

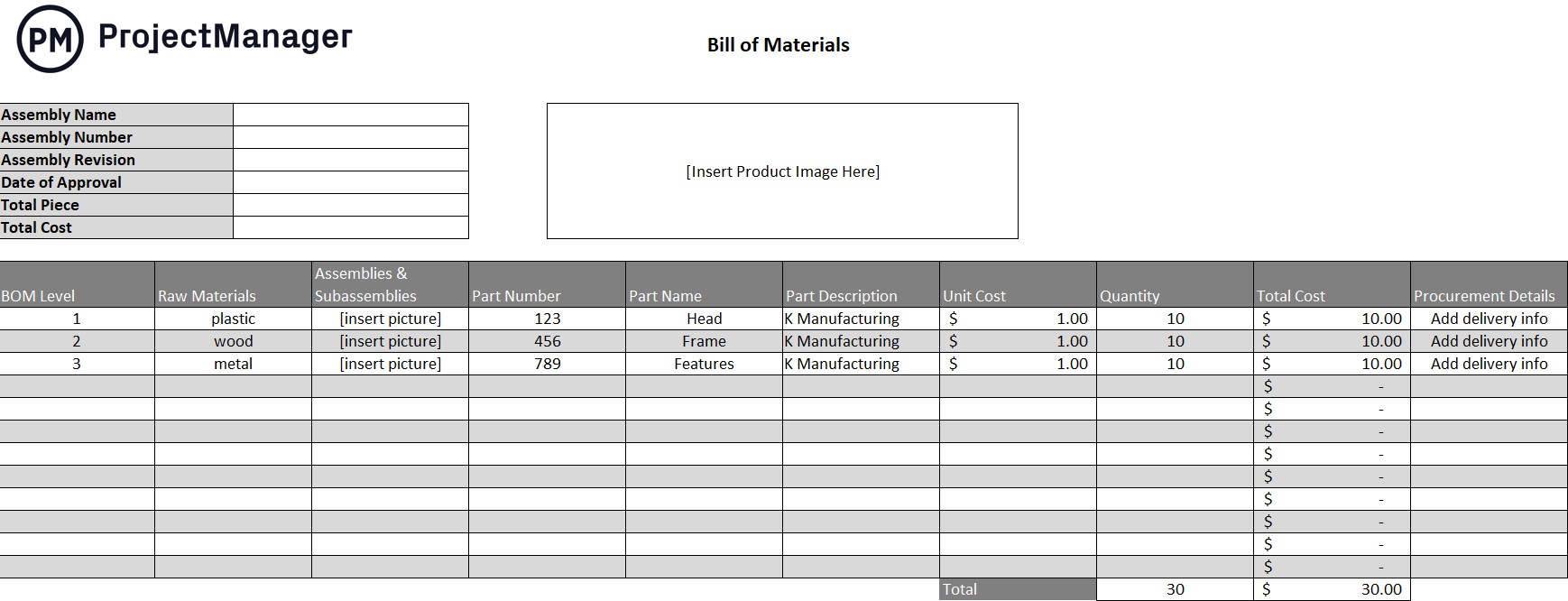

To be truly effective, a construction Bill of Materials needs to be thorough and well-organized. It should leave no room for ambiguity and provide all the necessary details for purchasing, tracking, and installation. A comprehensive BOM helps multiple departments, from purchasing to on-site teams, understand exactly what is required, ensuring everyone is on the same page and working with the same data.

Here are the essential elements typically found in a robust construction BOM:

- **Item Number/ID:** A unique identifier for each material or component for easy tracking.

- **Description:** A clear and precise description of the material, including specifications, brand, or model where applicable.

- **Unit of Measure:** The standard unit for purchasing and tracking (e.g., linear feet, square meters, each, kilograms, boxes).

- **Quantity Needed:** The exact amount of the material required for the project based on plans and calculations.

- **Unit Cost:** The price per unit of the material.

- **Total Cost:** The calculated cost for the total quantity of each item (Quantity Needed x Unit Cost).

- **Supplier Information:** Details of potential or preferred suppliers for each item.

- **Notes/Specifications:** Any additional instructions, quality requirements, or installation details relevant to the material.

Incorporating these elements helps procurement teams make informed decisions, ensuring the right materials are ordered at the right time and at the best possible price. It also aids in inventory management, reducing the risk of over-ordering and the associated storage costs, or under-ordering which can lead to costly project pauses. Ultimately, a well-defined BOM minimizes errors, facilitates smoother workflows, and enhances communication across all project stakeholders.

Streamlining Your Projects with a Construction Bill of Materials Template

While understanding the importance of a Bill of Materials is crucial, the real game-changer for many project managers and contractors is leveraging a pre-designed construction bill of materials template. Instead of starting from scratch for every new project, which can be incredibly time-consuming and prone to human error, a template provides a standardized framework. This pre-formatted structure ensures that all critical fields are included and consistently organized, allowing teams to focus on filling in the specific project details rather than designing the document itself.

The efficiency gained from using a template is substantial. Imagine having a ready-made spreadsheet or digital form where you simply plug in the item descriptions, quantities, and costs. This dramatically speeds up the initial planning phase, allowing projects to move from concept to execution much faster. Furthermore, it promotes consistency across all projects, making it easier to compare data, analyze trends, and identify areas for improvement in your procurement processes over time. This standardization is invaluable for businesses managing multiple projects concurrently.

Beyond just saving time, a good construction bill of materials template significantly enhances accuracy and reduces the likelihood of omissions. Because the template guides you through each necessary category—from item numbers to unit costs and quantities—it acts as a checklist, ensuring that no vital piece of information is overlooked. This systematic approach minimizes the risk of last-minute surprises, such as discovering you forgot to account for specific hardware or a type of insulation.

Here are some key benefits of integrating a template into your construction workflow:

- **Saves Significant Time and Effort:** No need to design the document from scratch for each project.

- **Ensures Consistency:** All BOMs follow a uniform structure, making them easy to understand and compare.

- **Reduces Human Error:** Pre-defined fields and formulas minimize calculation mistakes and forgotten items.

- **Facilitates Collaboration:** Teams can easily understand and contribute to a standardized document.

- **Provides a Clear Record:** Serves as an excellent reference for audits, project reviews, and future planning.

- **Aids Negotiation:** A clear, detailed list strengthens your position when negotiating with suppliers.

Ultimately, adopting a reliable construction bill of materials template empowers project managers to maintain tighter control over their resources and budget. It fosters a proactive approach to project management, moving away from reactive problem-solving to a more organized and predictable execution model. This investment in organizational tools translates directly into smoother operations, improved financial performance, and greater client satisfaction throughout the entire construction process.

Implementing a well-structured Bill of Materials is a fundamental step toward achieving greater efficiency and profitability in the dynamic world of construction. It provides the clarity and control necessary to navigate complex projects, ensuring every nail, beam, and tile is accounted for. By embracing this level of detail, you empower your team to make informed decisions, minimize waste, and stick to budgetary constraints with greater precision.

The strategic advantage of having a meticulously prepared materials list cannot be overstated. It transforms potential chaos into order, allowing you to optimize resources, reduce unexpected expenses, and ultimately deliver projects on time and within budget. This systematic approach is not just about managing materials; it’s about building a stronger foundation for the success and sustainability of your construction business.