In the intricate world of manufacturing and product development, precision is not just a goal; it is an absolute necessity. Every single component, every tiny screw, and every complex assembly must be accounted for to ensure a smooth production line and a high-quality end product. This is where a Bill of Material, or BOM, steps in as the foundational document, detailing every part needed to build something, along with its quantity and specifications.

However, simply having a BOM isn’t enough. The true power lies in its structure, clarity, and ease of use. This is precisely why a well-designed bom bill of material template becomes an indispensable tool for businesses of all sizes, from startups crafting their first prototype to established enterprises managing vast product portfolios. It brings consistency, reduces errors, and streamlines the entire process from design to delivery.

Why a Robust BOM Template is Your Production Blueprint

Imagine trying to assemble a complex piece of machinery or even a simple piece of furniture without a clear list of parts. Chaos would ensue, right? In manufacturing, that chaos translates into costly delays, wasted materials, and frustrated teams. A comprehensive Bill of Material acts as the authoritative source of truth for all components, sub-assemblies, and raw materials required to produce a finished item. It bridges the gap between design, purchasing, manufacturing, and even sales, ensuring everyone is on the same page regarding what needs to be made and what goes into it.

Utilizing a standardized template elevates this critical document from a mere list to a powerful operational asset. It guarantees that every BOM created follows a uniform structure, making it incredibly easy for different departments to read, understand, and act upon the information. This consistency drastically reduces the chances of misinterpretation, incorrect orders, or production bottlenecks caused by missing parts. Moreover, a template often includes pre-defined fields, prompting users to include all necessary data, preventing oversight.

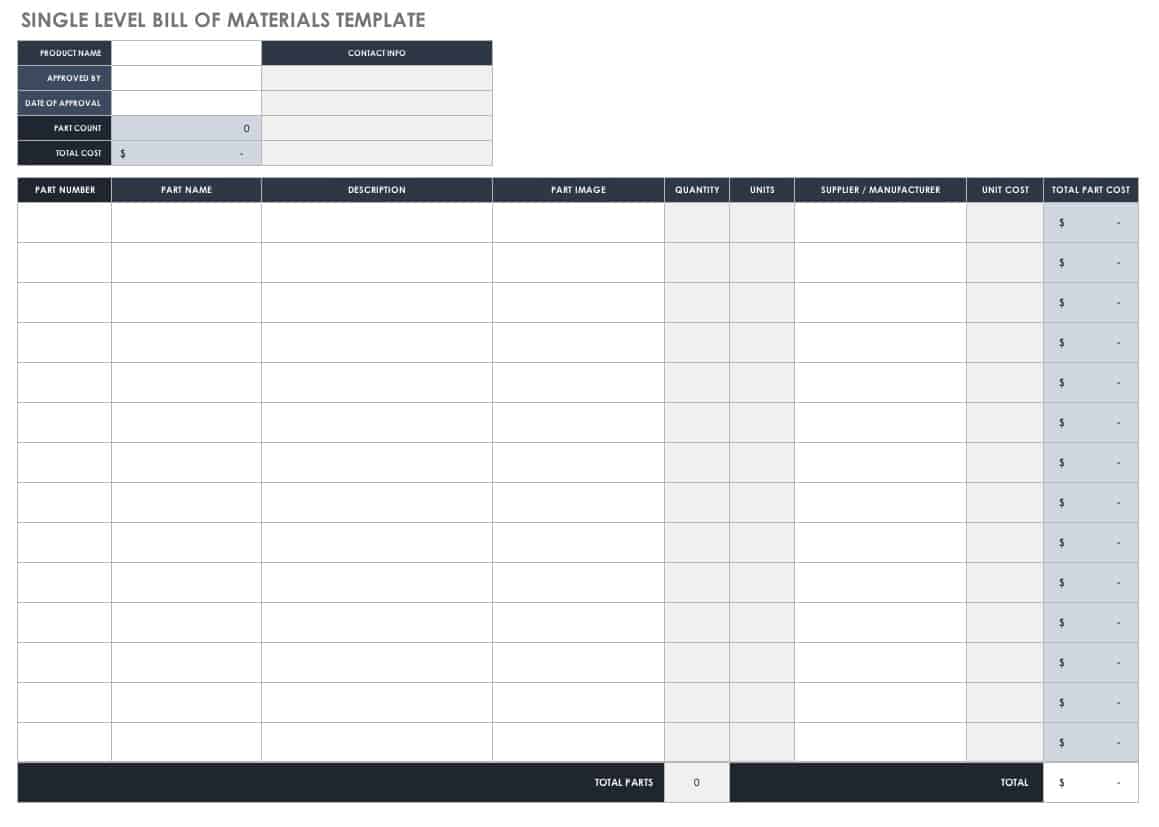

Key Sections You’ll Find in a Comprehensive Template

A good bom bill of material template isn’t just a blank spreadsheet; it’s a carefully thought-out structure designed to capture all essential data points. While specific fields might vary based on the industry or product complexity, several core sections are universally beneficial:

- Part Number: A unique identifier for each component or assembly.

- Part Name: A clear, descriptive name for the item.

- Description: Additional details about the item, its specifications, or purpose.

- Quantity: How many units of this item are needed for one unit of the final product.

- Unit of Measure: The unit in which the quantity is measured (e.g., pieces, meters, liters).

- Material Type: The type of material the part is made from.

- Manufacturer/Vendor: Who supplies the part.

- Cost: The unit cost of the item.

- Revision Level: Tracks changes and versions of the BOM itself or the part.

- Notes/Comments: Any additional relevant information or special instructions.

By including these key elements, a template helps to create a living document that is not only accurate but also rich in information, supporting various operational functions beyond just assembly. It becomes a critical reference for inventory management, procurement, cost estimation, and quality control.

Customizing and Implementing Your Bill of Material Template Effectively

While a generic template can provide a good starting point, the real magic happens when you tailor it to fit your specific operational needs and product complexities. Not all BOMs are created equal; for instance, an Engineering BOM (EBOM) might focus more on design specifications and engineering revisions, whereas a Manufacturing BOM (MBOM) will detail every item needed for production, including packaging and waste allowances. Similarly, a Sales BOM (SBOM) might list components for a configurable product package for customers. Understanding these distinctions allows you to adapt your chosen template or even create multiple templates for different purposes.

When it comes to finding or building your ideal template, you have several options. Many enterprise resource planning (ERP) systems and product lifecycle management (PLM) software packages offer integrated BOM functionalities with customizable templates. Alternatively, you can find numerous free or paid templates online, often in spreadsheet formats like Excel, which can be easily modified. For more specialized needs, designing a custom template from scratch, perhaps in collaboration with your engineering and production teams, ensures it perfectly aligns with your workflow and data requirements.

Effective implementation goes beyond just filling in the fields. It involves establishing clear processes for how BOMs are created, updated, and approved. This includes defining roles and responsibilities for BOM creation and maintenance, setting up a robust version control system to track changes, and ensuring all relevant stakeholders have access to the latest approved version. Training your team on how to correctly use the bom bill of material template is also crucial to ensure consistency and data integrity across the board.

Regularly reviewing and refining your template is also key to its long-term effectiveness. As products evolve, processes change, and new technologies emerge, your BOM structure may need to adapt. Periodically gathering feedback from engineering, production, and procurement teams can help identify areas for improvement, ensuring your template remains a relevant and powerful tool for managing your product data. This proactive approach helps maintain accuracy and keeps your manufacturing operations running smoothly.

Adopting a structured approach to your product documentation, spearheaded by a well-crafted template, is a strategic move that pays dividends. It transforms a potentially chaotic data management task into a streamlined, efficient process, minimizing errors and maximizing productivity. Such a foundation provides clarity at every stage of the product lifecycle, from initial design to final assembly, ensuring every part is where it needs to be, when it needs to be there.

Ultimately, investing time in developing and refining your internal processes around a robust Bill of Material template leads to significant operational improvements. It fosters better communication between departments, enhances inventory control, optimizes procurement strategies, and lays a solid groundwork for scalable growth. This commitment to detail helps to drive not just efficiency, but also cost savings and a higher quality output for your business.