In today’s competitive business landscape, the quality of your final product or service is intrinsically linked to the quality of your inputs. This means the suppliers you choose and how you manage them are absolutely critical. It’s not just about getting the lowest price; it’s about ensuring consistency, reliability, and compliance throughout your entire supply chain. Managing these relationships effectively can feel like a daunting task, especially when you have numerous external providers.

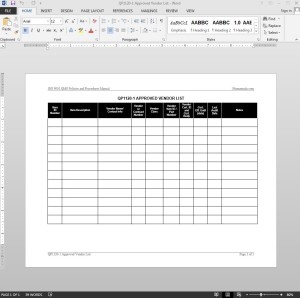

For organizations committed to quality, especially those working towards or maintaining ISO 9001 certification, a systematic approach to supplier management isn’t just a good idea—it’s a requirement. This is where an effective iso 9001 approved supplier list template becomes an indispensable tool. It provides a structured way to evaluate, approve, monitor, and manage all your external providers, ensuring they meet your quality standards and contribute positively to your operations.

Imagine having a clear, organized system that not only helps you identify the best partners but also demonstrates your commitment to quality in every step of your process. This article will guide you through the essentials of creating and utilizing such a list, transforming a potentially complex area into a streamlined, compliant, and highly effective part of your quality management system.

Why a Robust Approved Supplier List Is Non-Negotiable for ISO 9001 Compliance

The ISO 9001 standard places significant emphasis on “external providers” – a broad term encompassing anyone supplying products or services that affect your organization’s ability to consistently meet customer and applicable statutory and regulatory requirements. Clause 8.4, specifically, outlines the need for processes to ensure externally provided processes, products, and services conform to requirements. This isn’t just about avoiding problems; it’s about embedding quality control at every stage, starting with who you partner with.

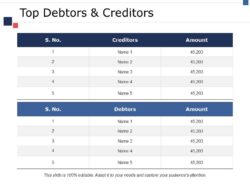

A well-maintained approved supplier list offers numerous benefits beyond mere compliance. It helps mitigate risks associated with poor quality inputs, ensures business continuity by identifying reliable partners, and can even lead to cost savings through reduced waste and rework. Furthermore, it fosters stronger relationships with your suppliers, encouraging them to align with your quality objectives and performance expectations. When audit time comes around, having this list readily available, along with supporting performance data, makes demonstrating compliance much smoother.

To be truly effective, an approved supplier list needs to be more than just a roll call of names. It should be a dynamic document that provides a comprehensive overview of each supplier’s status, performance, and the products or services they provide. Think of it as a living record that helps you make informed decisions about your supply chain, ensuring that every external input aligns with your organization’s commitment to quality and customer satisfaction.

Key Information to Include in Your Approved Supplier List

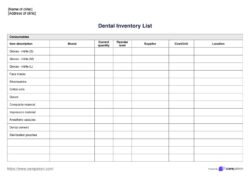

While specific requirements may vary slightly based on your industry and the nature of your relationships, a comprehensive approved supplier list template should generally include the following essential details:

- **Supplier Name and Contact Information:** Basic but crucial for communication.

- **Products/Services Provided:** A clear description of what the supplier provides.

- **Approval Status:** Clearly indicating whether the supplier is “Approved,” “Conditionally Approved,” or “Rejected,” along with the rationale.

- **Date of Approval and Review Dates:** Showing when they were approved and when their performance was last reviewed, demonstrating ongoing management.

- **Performance Metrics:** Space to record key performance indicators (KPIs) such as on-time delivery, quality conformity, responsiveness, and defect rates.

- **Risk Assessment Level:** A categorization of the risk associated with using this supplier (e.g., high, medium, low), influencing monitoring intensity.

- **ISO Certification Status (of the supplier):** If applicable, noting whether the supplier itself holds relevant ISO certifications.

- **Evaluation Criteria and Results:** A brief summary or reference to the initial evaluation criteria used for approval.

Including these details transforms your list from a simple directory into a powerful management tool. It enables you to quickly assess a supplier’s history, evaluate their current performance, and make data-driven decisions about their ongoing suitability. This level of detail is exactly what ISO 9001 auditors look for when assessing your control of externally provided processes, products, and services.

The process of getting a supplier onto this approved list should itself be well-defined. It typically involves an initial evaluation process, which might include questionnaires, site visits, review of samples, or assessment of their own quality management systems. Once approved, the work doesn’t stop. Regular performance monitoring, periodic re-evaluations, and a clear process for addressing non-conformities are all vital for maintaining the integrity and effectiveness of your approved supplier list.

Getting Started with Your Iso 9001 Approved Supplier List Template

Embarking on the journey of creating or refining your approved supplier list doesn’t have to be overwhelming. The most practical first step is often to leverage an existing iso 9001 approved supplier list template. These templates provide a solid foundation, ensuring you don’t miss any critical information and giving you a structured format to work with. You can find many generic templates online, often in spreadsheet formats, which are easily adaptable to most business needs.

Once you have a template, the key is to customize it to fit your specific organizational context and the unique requirements of your industry. Think about the types of suppliers you engage with, the criticality of their products or services, and the specific performance metrics that matter most to your operations. For example, a food manufacturer might emphasize hygiene and regulatory compliance heavily, whereas a software development firm might prioritize data security and response times.

Implementing your approved supplier list effectively involves more than just filling out a spreadsheet. It requires integrating it into your daily operations. Ensure that relevant staff members, from procurement to quality control, are aware of its existence, understand its purpose, and know how to use it. Regular training, clear communication channels, and scheduled review cycles will ensure that your list remains current, accurate, and a genuinely valuable asset to your quality management system. Remember, a robust supplier list is a dynamic tool that evolves with your business and its needs.

By diligently managing your approved suppliers, you’re not just ticking a box for ISO 9001; you’re actively building a more resilient, reliable, and higher-quality operation. It provides confidence in your inputs, reduces operational headaches, and ultimately enhances your ability to deliver excellent products and services to your customers consistently. This proactive approach to supplier management is a cornerstone of sustainable business success and continuous improvement.

Ultimately, a well-implemented approved supplier list becomes a strategic asset, providing clarity, control, and a pathway to stronger supplier relationships. It empowers your organization to make informed decisions, minimize risks, and maintain the high standards that define quality in today’s marketplace, ensuring that every external contribution aligns with your overarching commitment to excellence.