Embarking on any construction or renovation project, whether it is a small home improvement or a large commercial build, can feel like navigating a complex maze. There are countless details to consider, from initial design concepts to the final coat of paint. One of the biggest challenges, and often a source of stress, is accurately estimating the materials you’ll need. Getting this wrong can lead to costly delays, budget overruns, and frustrating trips back and forth to the supplier.

This is precisely where a reliable material take off list template becomes an indispensable tool. It provides a structured approach to identifying, quantifying, and documenting all the materials required for your project. Think of it as your project’s shopping list, but with far more detail and precision, ensuring you don’t forget that crucial bag of cement or those specific electrical conduits. It helps streamline your planning and procurement processes right from the start.

By having a clear and organized list, you gain better control over your project’s resources and budget. It fosters greater efficiency, reduces waste, and ultimately contributes to a smoother, more successful outcome. Let’s dive deeper into why this simple yet powerful document can be the cornerstone of your next project’s success.

Why a Material Take Off List Template is Your Project’s Best Friend

Accurate material estimation is more than just good practice; it is fundamental to the financial health and timely completion of any construction venture. Without a precise understanding of what materials are needed and in what quantities, you risk either under-ordering, leading to frustrating downtime while you wait for new supplies, or over-ordering, which ties up capital in unused materials and creates disposal headaches. A well-structured template acts as a safeguard against these common pitfalls.

Beyond just preventing waste, an effective template helps you secure better pricing from suppliers. When you can provide a detailed and itemized list of your exact requirements, suppliers are often more willing to offer competitive quotes. This level of clarity removes guesswork for both parties and can significantly impact your overall project costs. It also ensures that communication with your purchasing department or external vendors is clear and unambiguous, reducing the chances of errors in ordering.

Key Elements to Include in Your Template

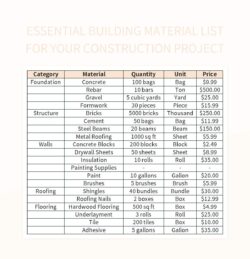

To truly maximize the benefits, your material take off list should be comprehensive and easy to understand. While specific fields might vary depending on the nature of your project, certain core elements are universally valuable. Including these in your template will ensure you capture all necessary information for efficient procurement and project management.

- Project Details: Name, location, date, estimator, and revision number.

- Item Number/ID: A unique identifier for each material.

- Description of Material: A clear and concise name for the item, including specifications like size, color, or grade.

- Unit of Measurement: How the material is purchased (e.g., linear feet, square meters, each, gallons, bags).

- Quantity Required: The precise number of units needed for the project.

- Waste Factor/Contingency: An additional percentage added to account for cuts, errors, or breakage.

- Supplier Information: Preferred vendor, contact details, and product codes.

- Unit Cost: The cost per unit of the material.

- Total Cost per Item: Quantity multiplied by unit cost.

- Delivery Date/Lead Time: When the material is expected or required on site.

- Notes/Comments: Any special instructions, considerations, or alternatives.

Incorporating these fields into your template allows for a systematic breakdown of every material component. This granular detail empowers you to track expenses with precision, making budget management a far more straightforward task. You can easily see where your money is going and identify areas for potential savings.

Furthermore, a detailed material take off list template supports better project scheduling. Knowing exactly when materials are needed and their lead times enables you to plan work phases more effectively, ensuring that crews are not idle waiting for supplies. It is a critical component of robust project planning that extends beyond mere cost tracking into overall operational efficiency. The more thoroughly you populate your template, the more insights you gain, reducing unexpected surprises and fostering a predictable workflow.

Crafting Your Own Effective Material Take Off List

While pre-made templates offer a great starting point, the most effective material take off list is often one that has been customized to fit the specific needs of your project type and workflow. You do not need to be a spreadsheet wizard to create a functional template. Simple tools like Microsoft Excel or Google Sheets can be incredibly powerful for this purpose. Start by listing the common materials for your type of work, then build out the columns for quantities, units, and costs.

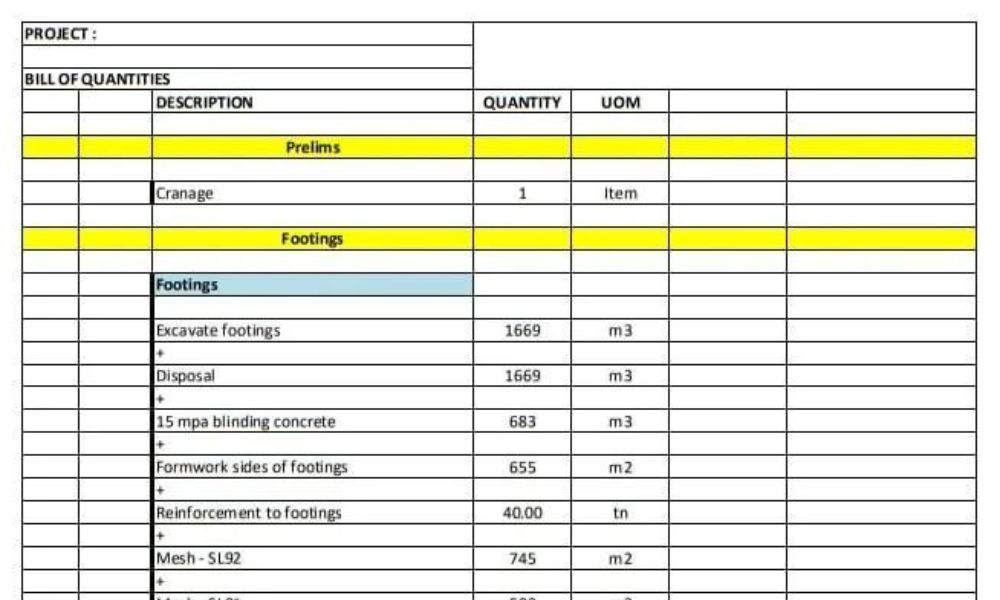

Think about the various stages of your project. Do you need separate sections for foundations, framing, electrical, plumbing, and finishes? Categorizing your materials can make the list less daunting and easier to manage. This segmentation also allows for phased ordering, where you procure materials only when they are needed for a specific stage, optimizing cash flow and storage space. Regularly reviewing and updating your template after each project also allows you to refine it based on real-world experience, making it even more accurate and useful for future endeavors.

Consider integrating formulas into your spreadsheet template to automatically calculate total costs per item and overall project material costs. This not only saves time but also minimizes calculation errors. Some project management software also offers built-in material take off functionalities that can link directly to your project schedule and budget. Regardless of the tool, the underlying principle of a structured, itemized list remains the same.

- Start simple with basic project details and material descriptions.

- Categorize materials by project phase or type (e.g., concrete, lumber, electrical).

- Always include a buffer for waste and unforeseen issues.

- Regularly review and update your template based on project experience.

Ultimately, a carefully prepared and utilized material take off list template becomes an invaluable asset that grows with your experience. It serves as a living document, evolving with each project to become more precise, more efficient, and more tailored to your unique requirements, ensuring a stronger foundation for every build.

Embracing the systematic approach of a well-designed material take off list significantly elevates your project management capabilities. It provides clarity, enhances communication, and offers an unprecedented level of control over your budget and timeline. By meticulously planning your material needs, you are not just listing items; you are laying the groundwork for a successful, stress-free, and profitable project delivery.

The effort invested in creating and utilizing this essential document pays dividends throughout the entire project lifecycle, from initial procurement to final completion. It empowers you to make informed decisions, mitigate risks, and achieve your project goals with confidence and efficiency.