Enhanced accuracy and repeatability are key advantages, minimizing errors and material waste. This leads to greater efficiency and a higher quality finish. The adaptability of such a device allows users to create a wide array of designs, expanding project possibilities. By streamlining complex routing operations, these tools contribute to increased productivity and reduced project timelines.

This foundation of understanding facilitates a deeper exploration of specific applications and techniques related to precise routing control and maximizing the potential of adaptable tooling.

Key Components

Effective use requires understanding the essential elements of these adaptable routing aids. The following components contribute to their precision and versatility.

1: Base Plate: A stable platform providing a consistent reference surface against the workpiece. Often constructed from durable, dimensionally stable materials like acrylic or aluminum.

2: Guide Bushings: Precision-machined sleeves surrounding the router bit, guiding it along the template edge. Available in various diameters to accommodate different bit sizes.

3: Adjustable Template Guides: Mechanisms enabling fine-tuning of the distance between the guide bushing and the template edge. This adjustability allows for precise control over cut depth and width.

4: Clamping System: Secures the template firmly to the workpiece, preventing movement during operation and ensuring accuracy. This can involve integrated clamps or compatibility with standard clamping tools.

5: Template Material: The template itself, commonly made from durable, easily machinable materials such as MDF, plywood, or high-density plastics. Its shape dictates the final routed profile.

Understanding the interplay of these components is critical for maximizing the utility and achieving optimal results with adjustable routing guides. Precise fabrication and proper adjustment of each element ensure accurate and repeatable outcomes.

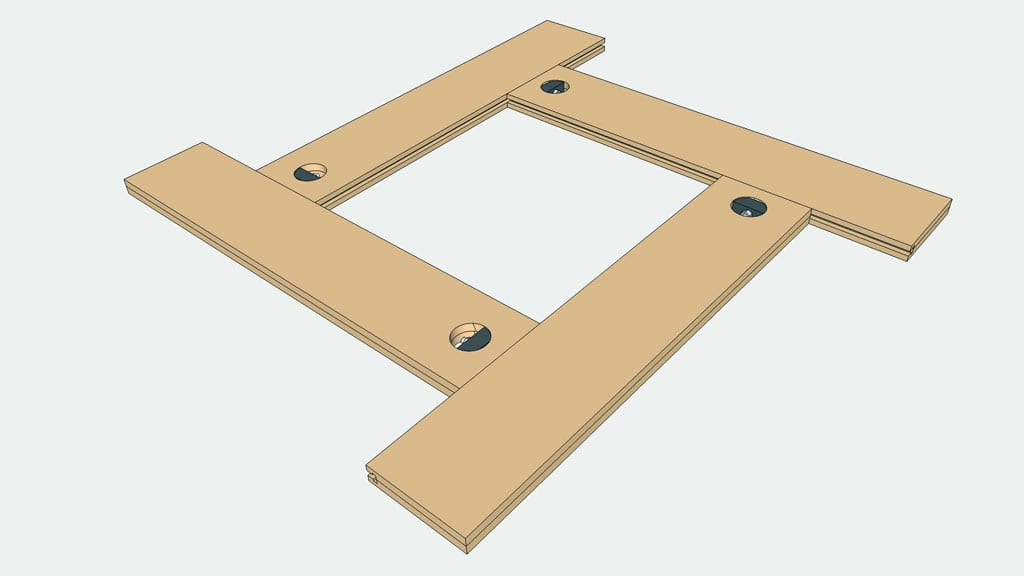

How to Create an Adjustable Router Guide Template

Creating a custom adjustable template expands routing capabilities, enabling precise control over complex profiles. The following steps outline the fabrication process.

1: Design the Template: Begin by meticulously planning the desired shape. Employ CAD software or precise hand-drawing techniques to create a detailed template design. Account for the router bit diameter and desired offset.

2: Material Selection: Choose a suitable template material. High-density materials like MDF, plywood, or acrylic offer stability and machining ease. The material thickness should be sufficient for secure clamping and guide bushing engagement.

3: Cut the Template: Precisely cut the template to the designed shape. Utilize a bandsaw, jigsaw, or CNC router for accurate cutting. Smooth edges minimize tear-out during routing operations.

4: Incorporate Adjustability: Implement a method for adjusting the guide bushing offset. This can involve slotted holes and threaded inserts, allowing for micro-adjustments of the bushing position relative to the template edge.

5: Integrate Clamping Mechanisms: Design features allowing secure clamping of the template to the workpiece. Consider integrated clamps, threaded inserts for bolt-down clamping, or compatibility with standard clamping tools.

6: Refine and Test: After fabrication, test the template on a scrap piece of material. Verify the adjustability range and ensure smooth, accurate routing operation. Refine the design as needed based on test results.

Meticulous design and precise fabrication are essential for creating an effective adjustable routing template. Careful material selection and incorporation of adjustability and clamping mechanisms contribute to a functional and durable tool, expanding routing capabilities significantly.

Adjustable router guide templates offer a significant advantage in woodworking and other material fabrication processes, enabling precise and repeatable routing operations. Understanding the key components, from the base plate and guide bushings to the clamping system and template material, is crucial for achieving optimal results. The ability to create custom templates further expands the potential applications, granting control over complex profiles and facilitating intricate designs. Precise fabrication and meticulous attention to detail in both design and execution are paramount for maximizing the effectiveness of these adaptable tools.

Ultimately, mastery of adjustable router guide templates empowers craftspeople and professionals to elevate the quality and efficiency of their work. This precision and control translate to greater project success, opening doors to intricate designs previously unattainable with conventional routing techniques. Continued exploration and refinement of these tools will undoubtedly lead to further advancements in material fabrication and design possibilities.