In the intricate world of product design and manufacturing, keeping track of every single component is not just good practice, it’s absolutely essential. Imagine assembling a complex machine only to discover a critical bolt is missing, or realizing you’ve ordered far too many of one part and not enough of another. That’s where a Bill of Materials, or BOM, steps in as your guiding light, providing a comprehensive list of every item, its quantity, and often its cost.

For those who rely on SolidWorks for their design needs, the power of a well-structured BOM cannot be overstated. It’s the backbone of your project, linking your design directly to procurement and production. While SolidWorks excels at generating BOMs automatically from your assemblies, the real magic happens when you leverage a customized solidworks bill of materials template, transforming raw data into an easily digestible, highly organized document that serves everyone involved in the product lifecycle.

What is a SolidWorks Bill of Materials Template and Why Do You Need One?

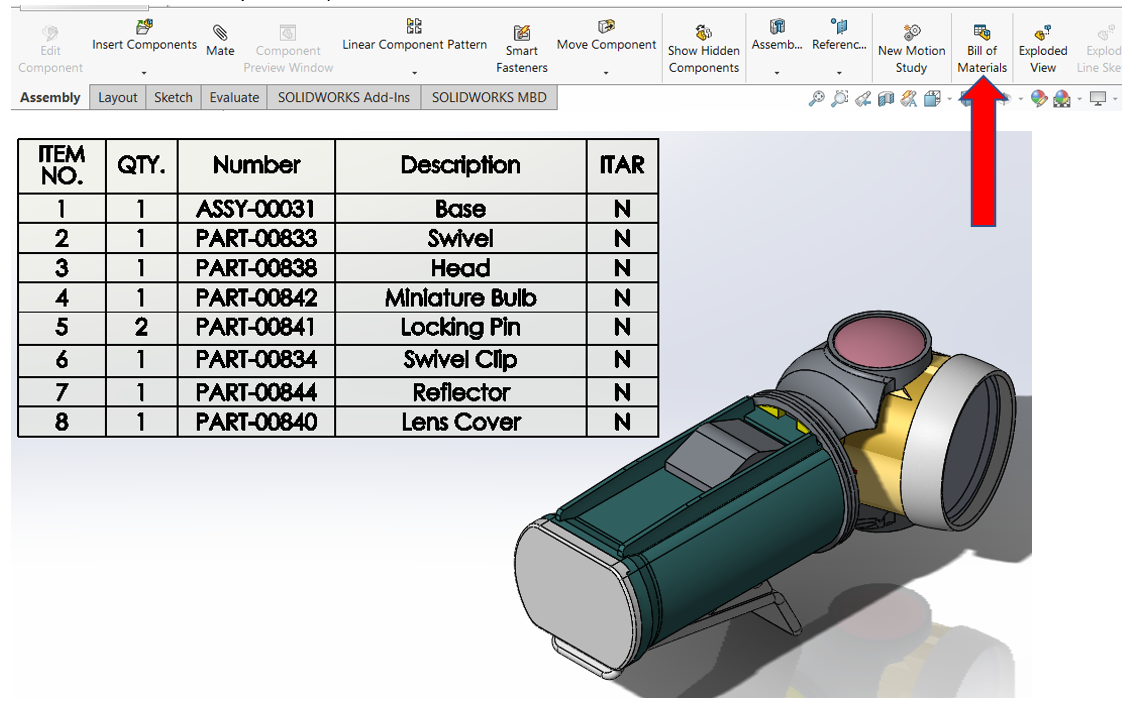

At its core, a SolidWorks Bill of Materials is a structured table that lists all the components within an assembly or sub-assembly. This includes everything from individual parts and fasteners to sub-assemblies themselves, along with crucial information like part numbers, descriptions, quantities, and often custom properties such as material, weight, or vendor details. SolidWorks automatically compiles this data from your 3D models, ensuring accuracy as your design evolves.

However, a raw BOM table, while informative, might not always be presented in the most user-friendly or brand-consistent manner for your specific workflows. This is where a solidworks bill of materials template becomes invaluable. It’s essentially a pre-defined layout and format for your BOM, allowing you to control which columns appear, their order, the column headers, font styles, and even company logos or specific notes. Think of it as tailoring the generic BOM output to perfectly fit your company’s internal standards and external communication needs, ensuring consistency across all your projects.

The “why” behind investing time in creating or refining such a template is rooted in efficiency and accuracy. Without a standardized template, each time you generate a BOM, you might find yourself manually adjusting columns, reformatting text, or ensuring all necessary data points are included. This repetitive work is not only time-consuming but also prone to human error, which can lead to costly mistakes in procurement or production. A template eliminates this guesswork and manual intervention.

Furthermore, a consistent BOM format significantly improves communication across different departments within your organization and with external partners. Purchasing knows exactly where to find part numbers and quantities, manufacturing sees the assembly order clearly, and quality control can easily cross-reference components. It fosters a shared understanding of the product, minimizing confusion and streamlining operations from design conception to final delivery.

Unlocking Efficiency: Key Benefits of a Standardized SolidWorks BOM Template

- Consistency Across Projects: Ensures all BOMs generated from SolidWorks have the same look, feel, and data structure, regardless of who created them.

- Reduced Manual Errors: Automates the inclusion of necessary data fields and formatting, minimizing human error in data entry and presentation.

- Faster Generation of BOMs: Saves significant time by eliminating the need for manual adjustments and formatting for each new BOM.

- Improved Communication: Provides a clear, unambiguous document that stakeholders, suppliers, and manufacturing teams can easily understand and act upon.

- Professional and Uniform Documentation: Enhances your company’s image with polished, branded documentation that reflects attention to detail.

Creating and Customizing Your SolidWorks Bill of Materials Template

SolidWorks offers robust tools that empower users to customize their Bill of Materials tables far beyond the default settings. This customization capability allows you to truly make your BOMs work for your specific needs, whether you need to include custom properties, reorder columns, or simply change the aesthetic to match your company’s branding. The process begins within a SolidWorks drawing, where you typically insert your BOM table.

Once you’ve inserted a BOM into your drawing, the real fun of customization begins. You can right-click on the table to access various options. Here, you have the power to add or remove columns based on the information critical to your workflow – perhaps you need columns for material specifications, a vendor code, or even a specific internal project number linked to a custom property in your SolidWorks files. You can also rename column headers to be more intuitive for your team, adjust column widths, and change text fonts or sizes to enhance readability.

A particularly powerful feature is linking BOM table cells directly to custom properties within your SolidWorks part and assembly files. This ensures that information like descriptions, materials, and part numbers automatically populate your BOM, directly pulled from the properties you’ve already defined in your models. This automation is key to maintaining accuracy and significantly reduces the effort required to update BOMs when design changes occur. Once you’ve configured your table exactly as you want it, you can save this layout as a .sldbomtbt file, which is your custom solidworks bill of materials template.

It’s highly recommended to save this template file in a shared network location or a designated folder that all SolidWorks users in your team can access. This ensures everyone is using the same standardized template, reinforcing consistency across all projects. Before rolling out a new template, it’s always a good idea to test it with a few representative assemblies and gather feedback from different departments who will be using the BOMs, ensuring it meets everyone’s needs and workflows effectively.

Embracing a tailored SolidWorks Bill of Materials template is more than just a convenience; it’s a strategic investment in the efficiency and accuracy of your entire product development process. It streamlines communication, minimizes errors, and ensures that vital information is consistently presented in a clear, professional format.

By taking the time to set up a robust template, you’re not just saving hours of manual work; you’re building a foundation for smoother collaboration and better decision-making across all stages of your project. It’s a key step towards optimizing your workflows and achieving greater success in bringing your designs to life.